The measurement

Our Research Center has performed refractory durability tests for over 35 years. Target groups have been flash smelting and converting units as well as copper melting and casting units. Ferroalloy smelting refractories have also been tested along with refractories suitable for some new process concepts.

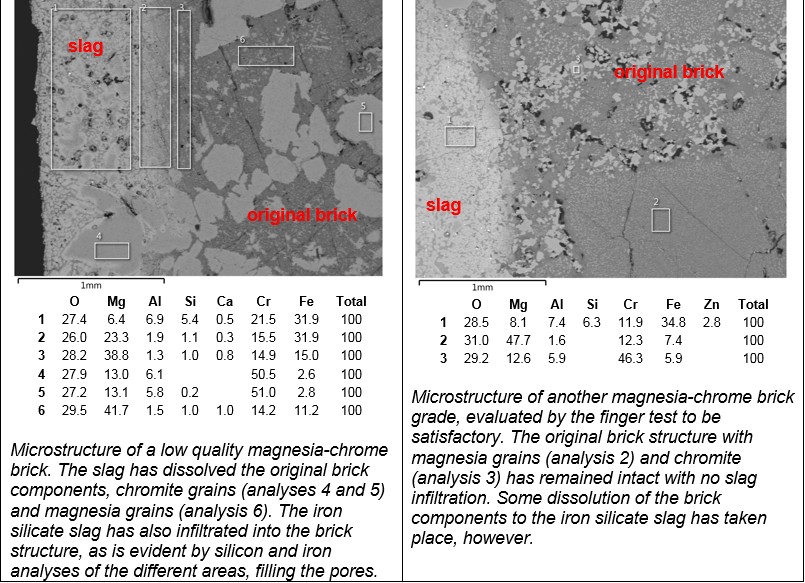

Tested refractory materials include magnesia chrome, magnesia, alumina-silica and carbon bricks or masses. The process melt has been typically slag, but matte and metal melts have been investigated as well. Best results can be expected if authentic slag or matte from a customer can be used. If not available, a reference melt can be utilized.

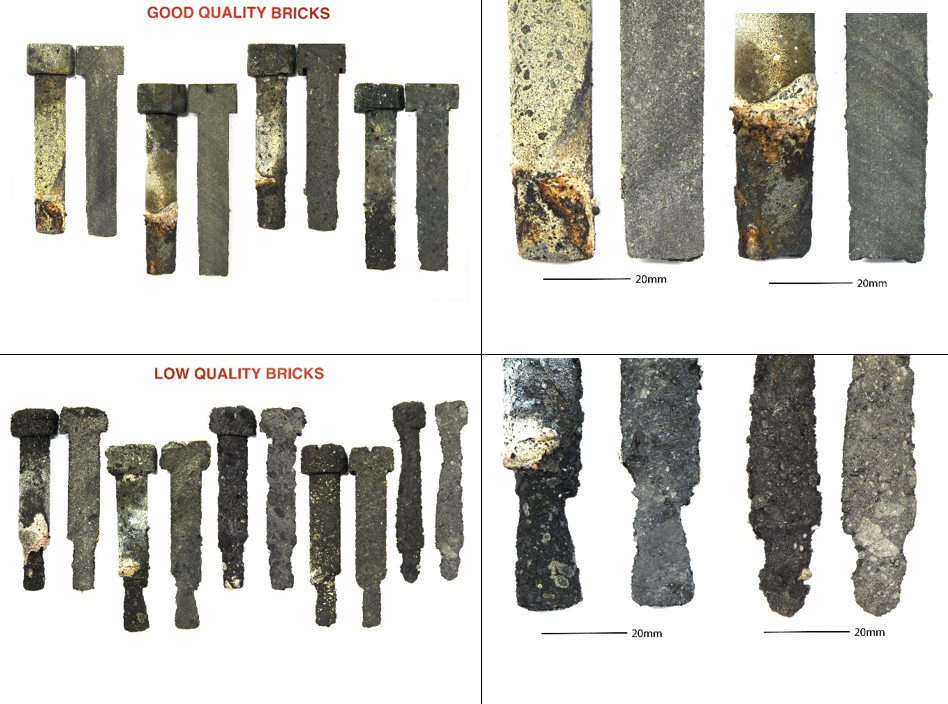

There are two options to measure the chemical durability of a refractory material: a finger test or a crucible test. The finger test is best suited for refractory brick materials and is the one most used, because it is dynamic and most accurately resembles the real operating conditions. The crucible test is best for refractory masses and for cases where the reactions with the refractories are unknown, i.e. new process concepts. It is static and does not mimic the vigorous melt movements as well as the finger method. Which method to use must be considered case by case.

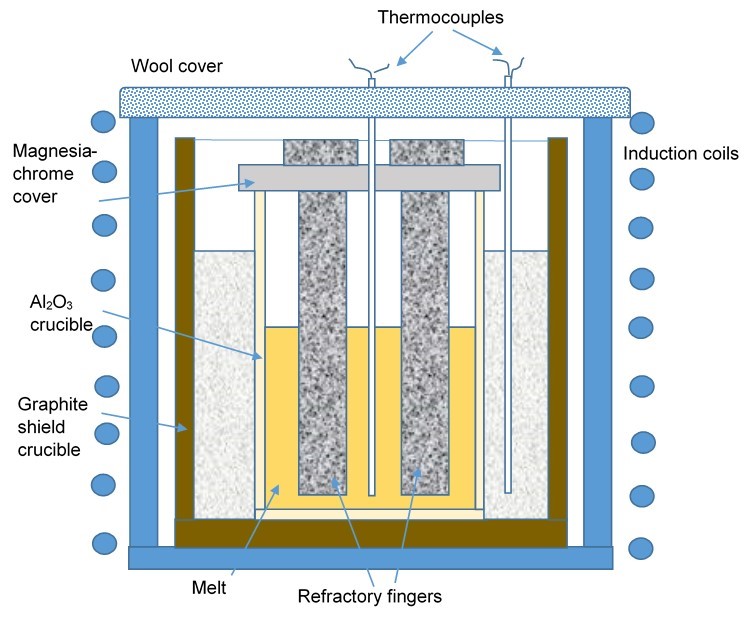

The finger and the crucible methods differ in the way the investigated refractory is introduced. In the finger test the refractory is the finger and the melt is held typically in an Al2O3 crucible. In the crucible method there is no finger and the melt is held in a crucible made out of the investigated refractory material.

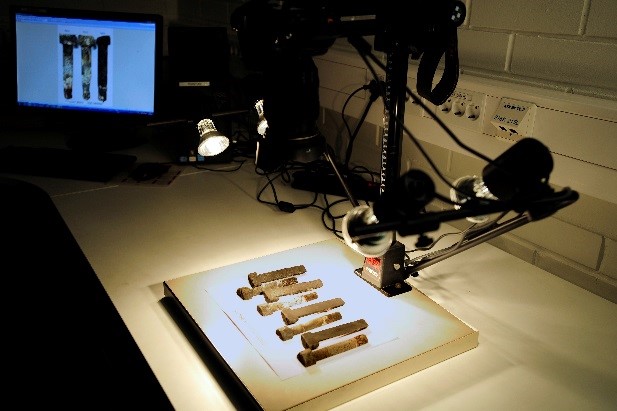

Testing starts with the preparation of the raw materials. Refractory brick fingers are drilled out of larger blocks and crucibles are prepared by drilling a cavity in the middle of a cubic or cylindrical sample block. The process material to form the melt is ground to a preferential particle size of < 2 mm, in order to allow filling the crucibles as full as possible. In some cases premelting of the material is required to prevent foaming in the actual test.

In the finger test, the crucible is then heated in an induction furnace where the melt is vigorously agitated by induction current, making the conditions dynamic. In the crucible test, crucibles are heated in a chamber furnace, rendering the conditions static. In both methods typically a temperature of 1450 oC, N2 or Ar atmosphere and duration of 6 hours has been applied. Other conditions are possible but then comparison to previous samples becomes cumbersome. After the test the fingers are lifted from the melt and the induction furnace current is turned off. In crucible tests the samples are cooled down with the furnace.