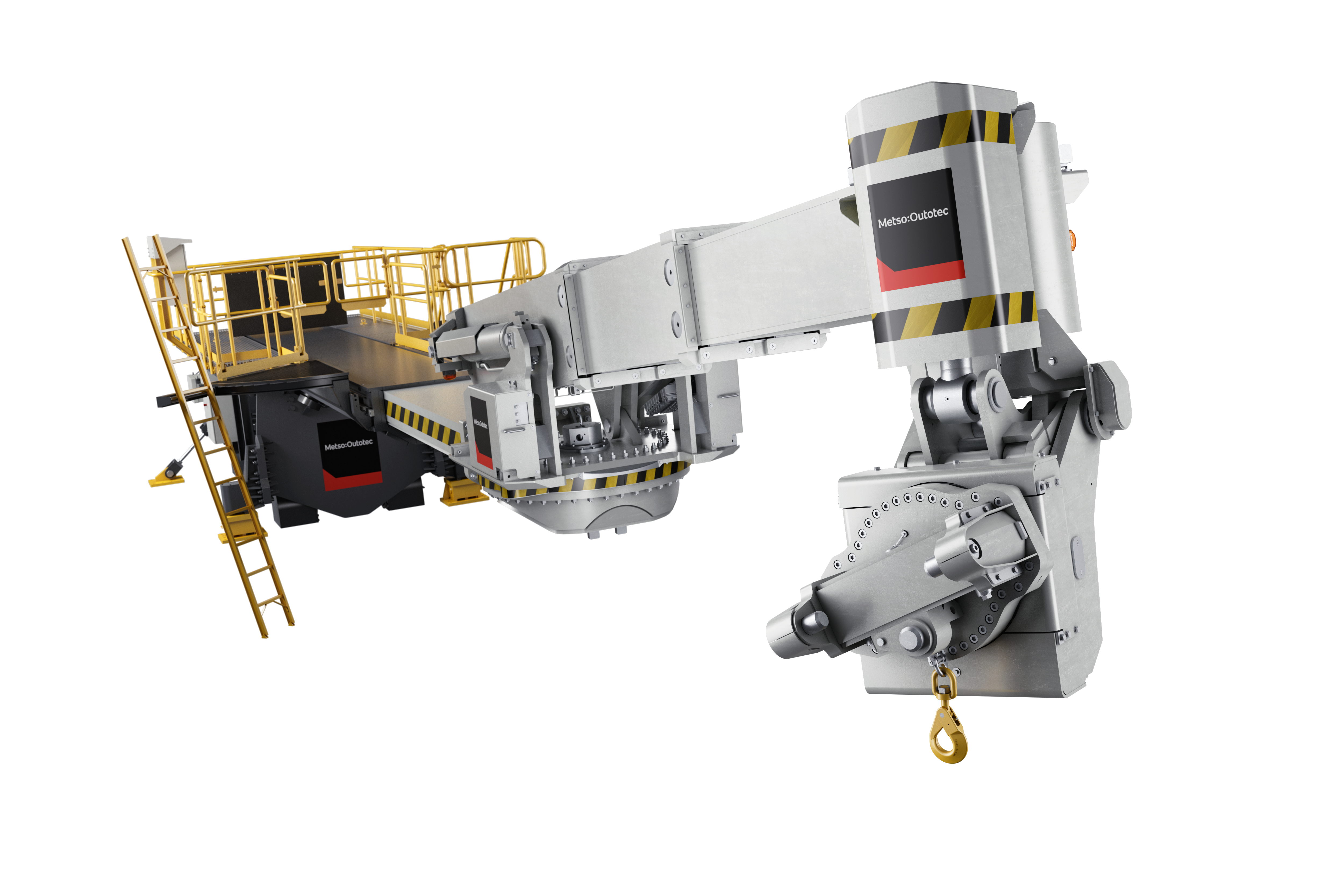

Training reline machine operators is difficult due to the uniqueness of the task and equipment involved. The unfortunate reality is that operators rarely get the opportunity to refine their skills and the few opportunities that do arise are under conditions that are far from ideal. This creates a high demand for the handful of highly experienced operators, making availability a serious concern and succession planning practically impossible.

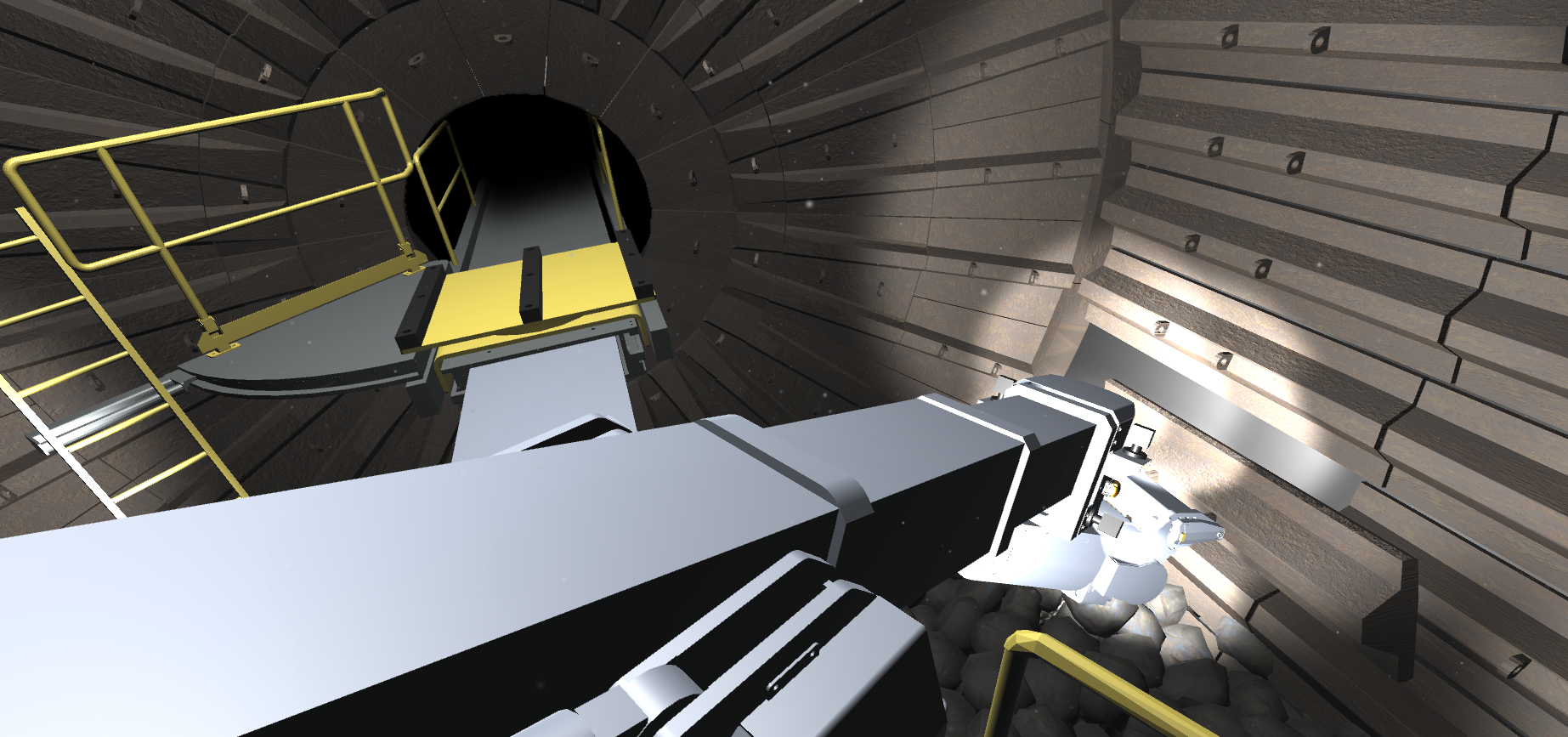

Over the years, multiple attempts have been made to address the lack of quality operator training options. However, by reviewing these approaches it becomes apparent that all have significant compromises and fail to address the issue. Considering these findings, a comprehensive solution is urgently required and thanks to recent developments in virtual reality technology, that solution has finally arrived.

Dedicated training facility

Perhaps the most obvious solution to training operators on any piece of equipment is to provide a dedicated training area in which they can learn safely and make mistakes without consequence. A handful of sites have invested in such a solution and have no doubt benefitted massively from improved operator skill. However, for most sites, access to such a facility is not feasible due to space or budget constraints.

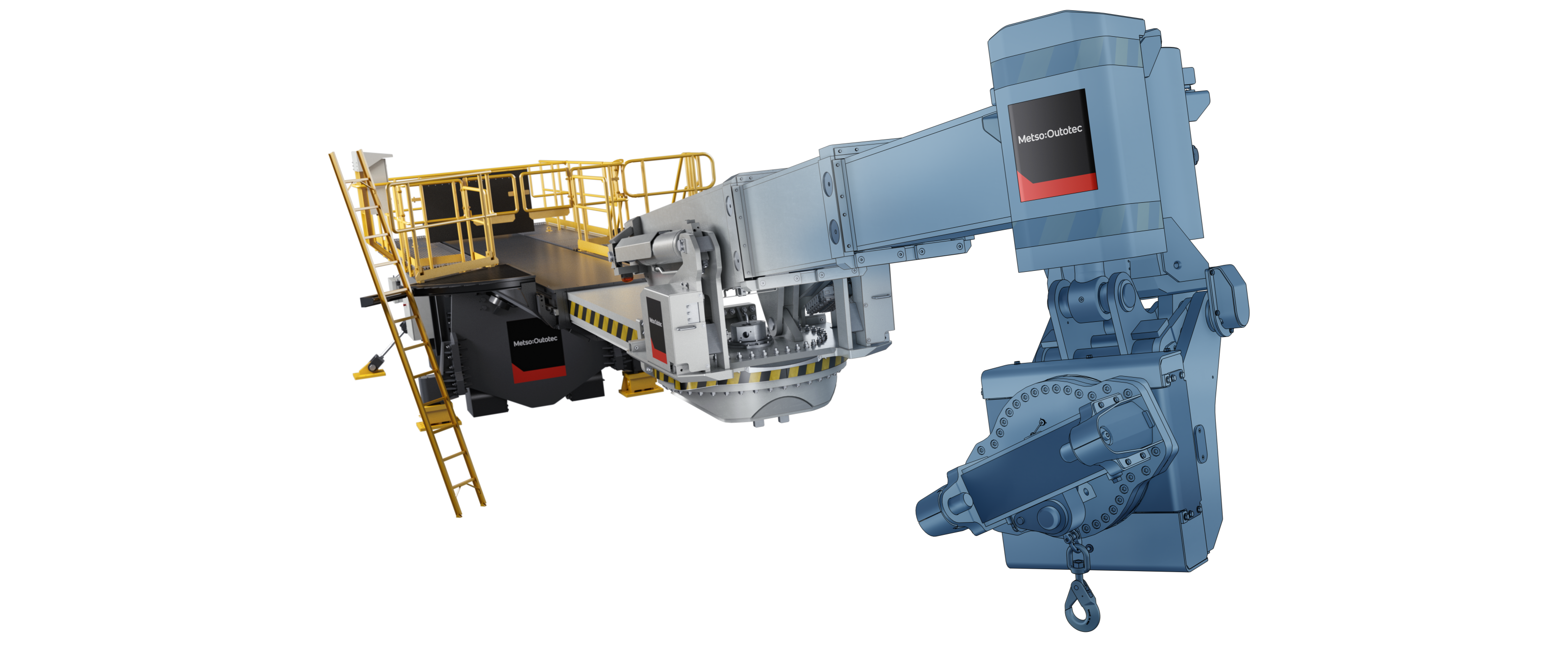

Mill reline machines are expensive, large and difficult to move over any significant distance. Traditionally this has meant that once a mill reline machine is placed on a mill deck, it stays there for the duration of its life. Mill decks are extremely optimized in plant layout planning, resulting in a deck so compact that even moving the reline machine from the storage location to the working location can prove difficult. A dedicated space for operator training is a luxury that is cut from typical plant design long before the first layout drawing is completed.