Failure modes

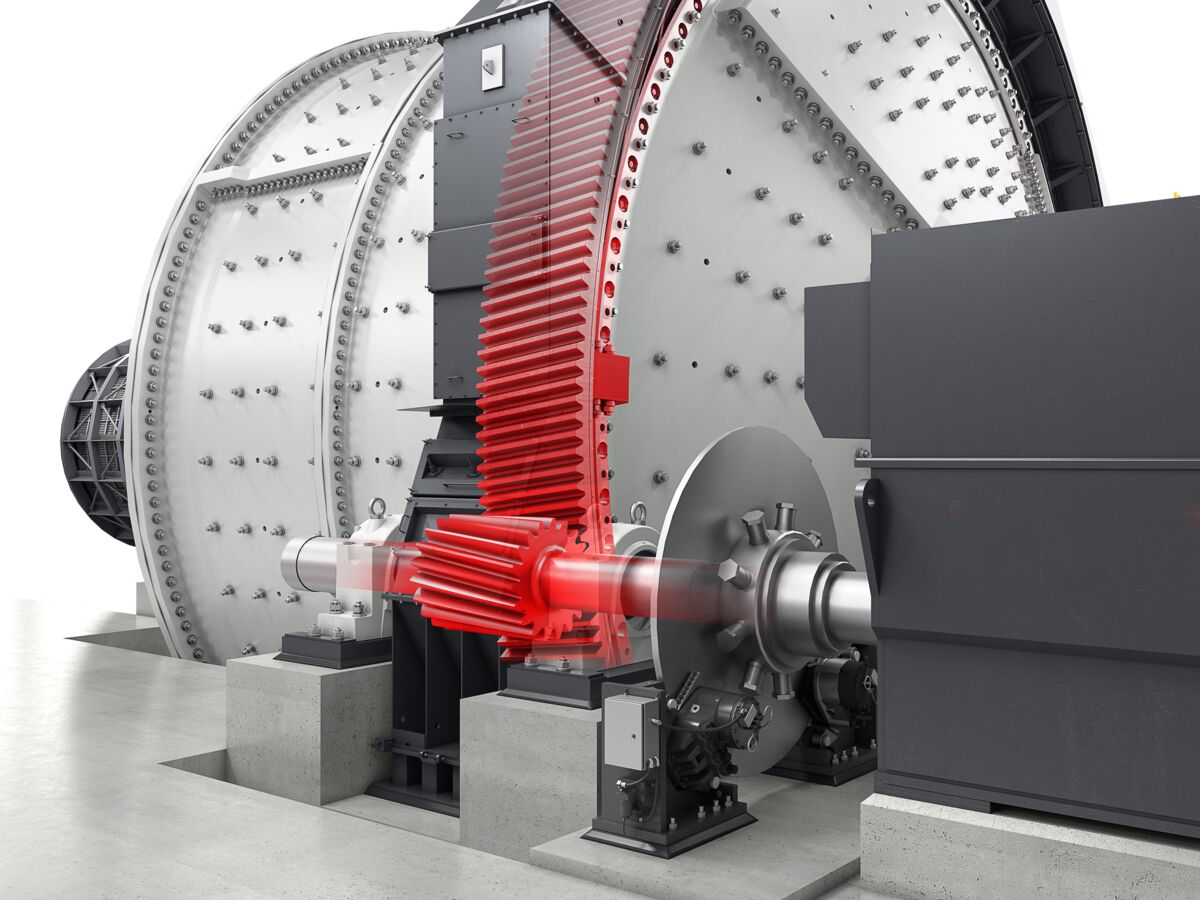

A failure mode is defined as a cause of failure of an equipment, component or system. Potential failure modes depicted here are based on known industry standard AGMA 1010-F14 for Appearance of Gear Teeth – Terminology of Wear and Failure. While simplified for the purpose of this article, to properly understand how common modes of gear failure are identified and measured, it is important to distinguish Class, Mode and Degree.

Class

A category regrouping different general modes. These include wear, scuffing, plastic deformation, Hertzian fatigue, cracking, fracture and bending fatigue.

Mode or General Mode

Known as general modes, is a family of modes classified within the same Class. As such, adhesion, abrasion and scaling are all categorized as wear.

Degree or Specific Mode

A degree is the level or extent to which the mode is present while a specific mode is an exact classification of a failure mode. For more common Classes such as wear and scuffing, the degree of different modes is classified as either mild, moderate or severe. Other Classes such as plastic deformation, Hertzian fatigue and bending fatigue will be defined with specific modes. Classes such as cracking and fracture do not have their modes classified under a degree nor a specific mode.

Most common failures

Gear failures are often a combination of one or multiple failure modes which can be retraced to one or many root causes related to either improper installation, operation or maintenance. In most cases, failures could be prevented through good practice. For better comprehension, the below summary provides a brief overview of the most common failures recorded on operating mill gears and pinions through empirical observations and experience with the equipment by paying close attention to terminology as described in AGMA 1010.

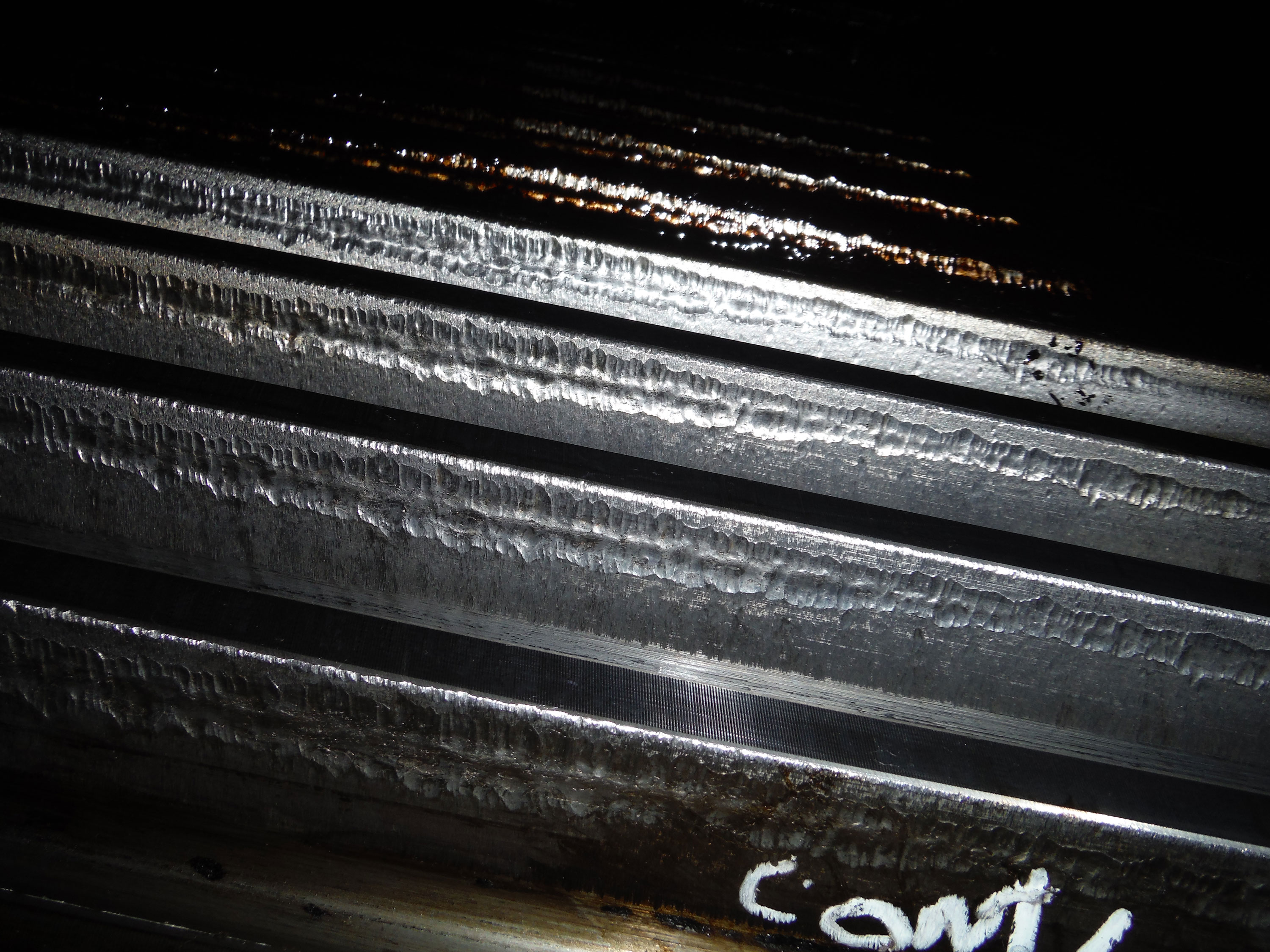

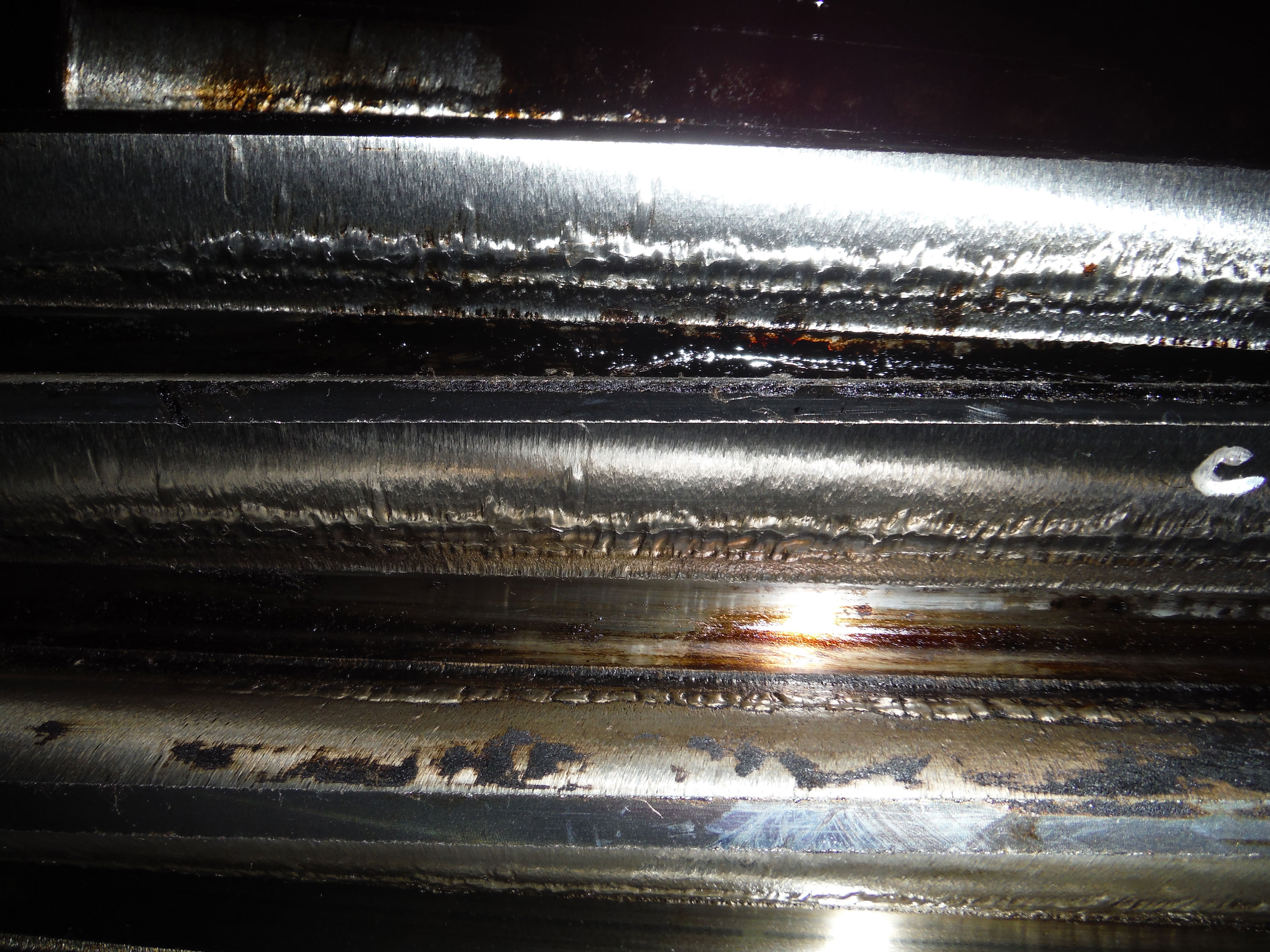

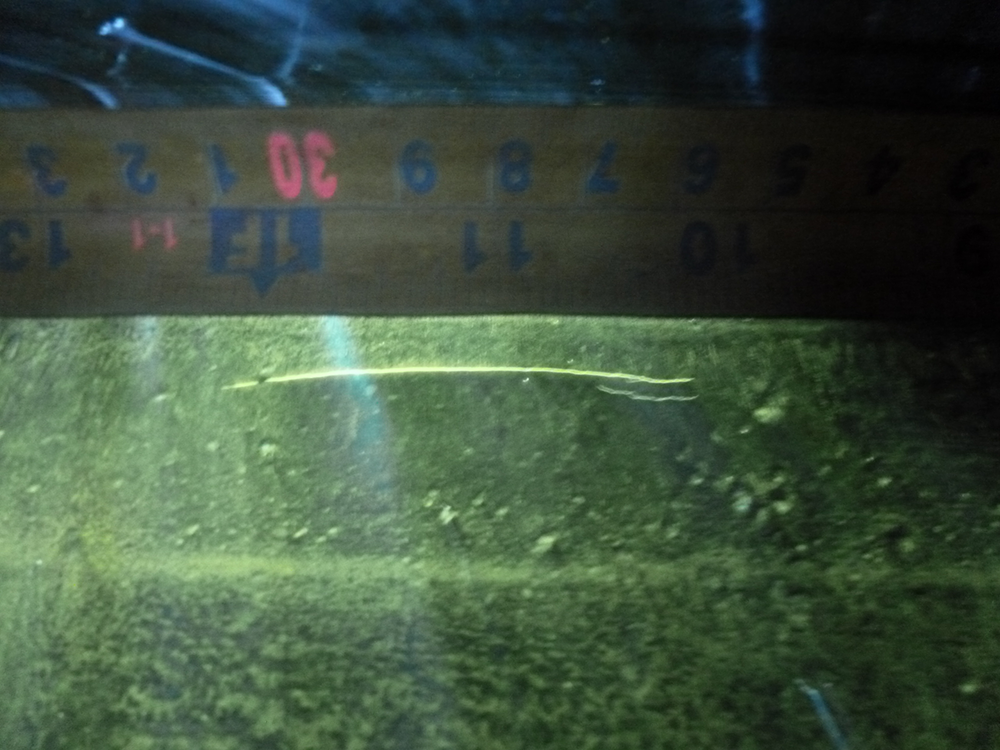

Wear

Modification to the gear tooth surface resulting in removal of material. Different general modes of wear have different appearances but all result in the disappearance of machining marks on teeth flanks which may serve as an early indication. Different sources of wear can include minor misalignment, loss of lubricant and contamination. While pinion wear can progress significantly faster than wear on the gear, due to the higher number of rotations, signs of wear to the gear will start to appear through transmission from a pinion with moderate wear. Pinion flipping or replacement is recommended to avoid transmitting additional wear to the gear.