The mining industry is undergoing significant changes in regards to sustainability and productivity. With the increasing demand for operations to be moving towards efficient and autonomous production, a key theme has emerged: Digitalization.

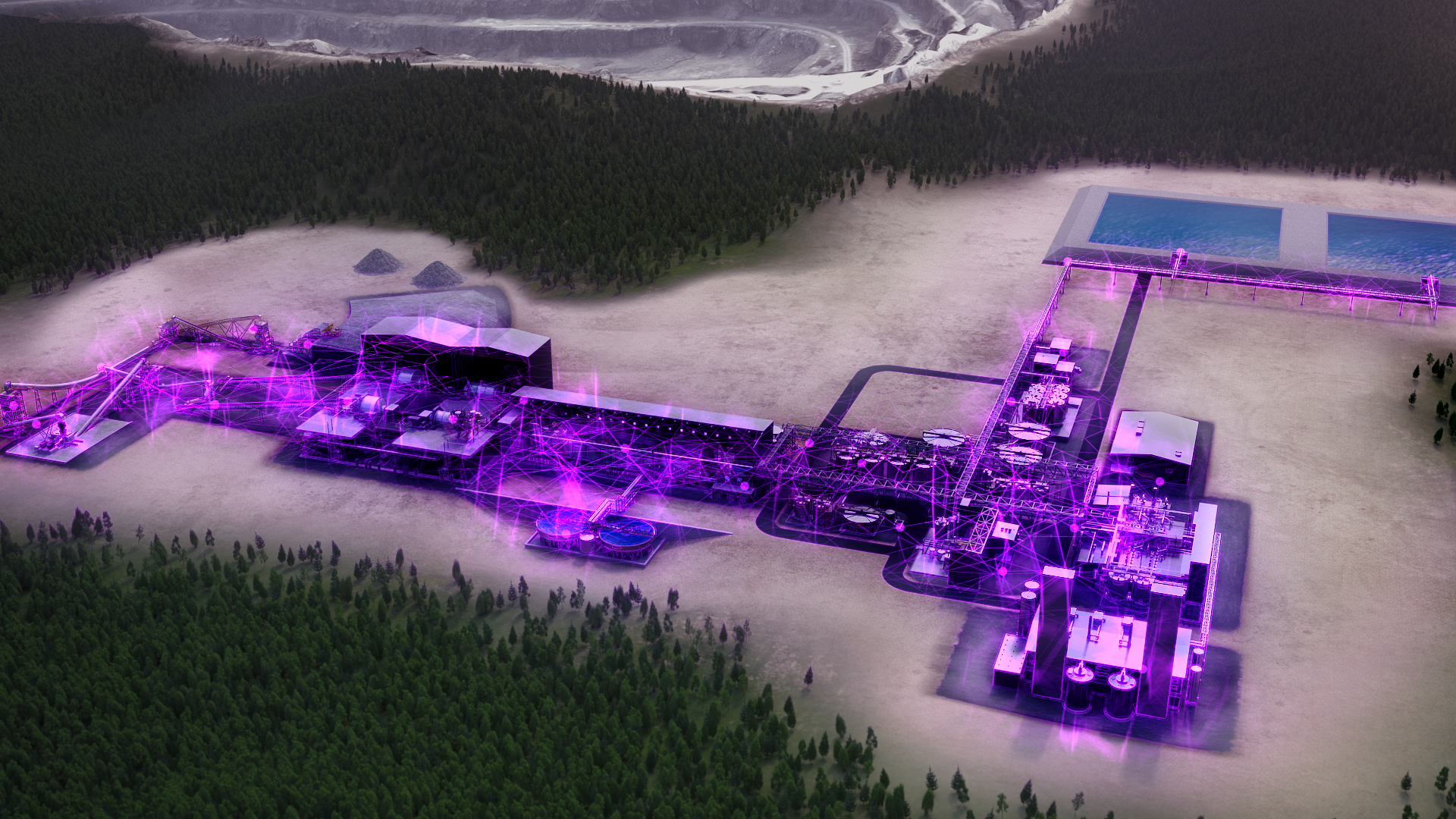

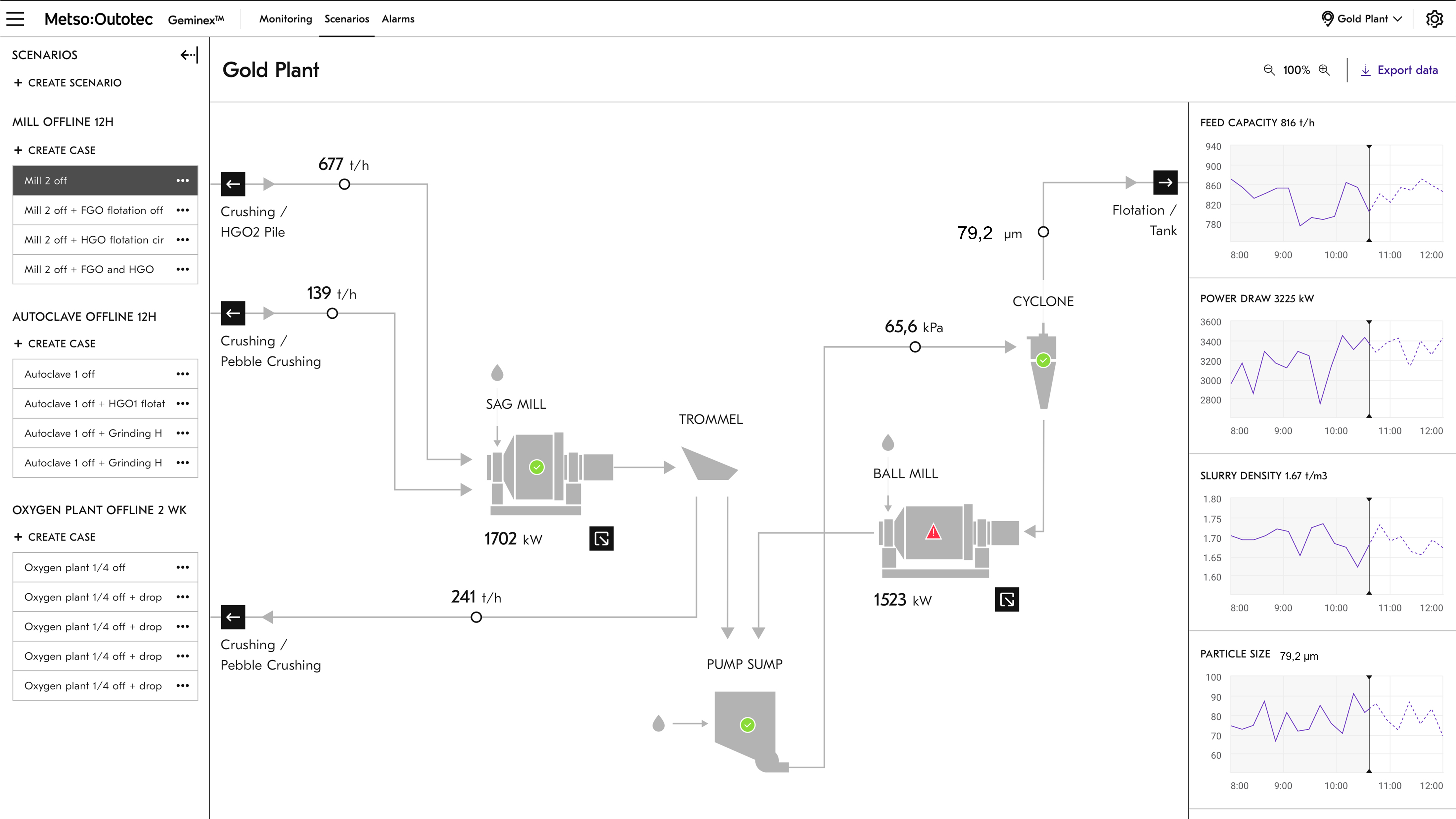

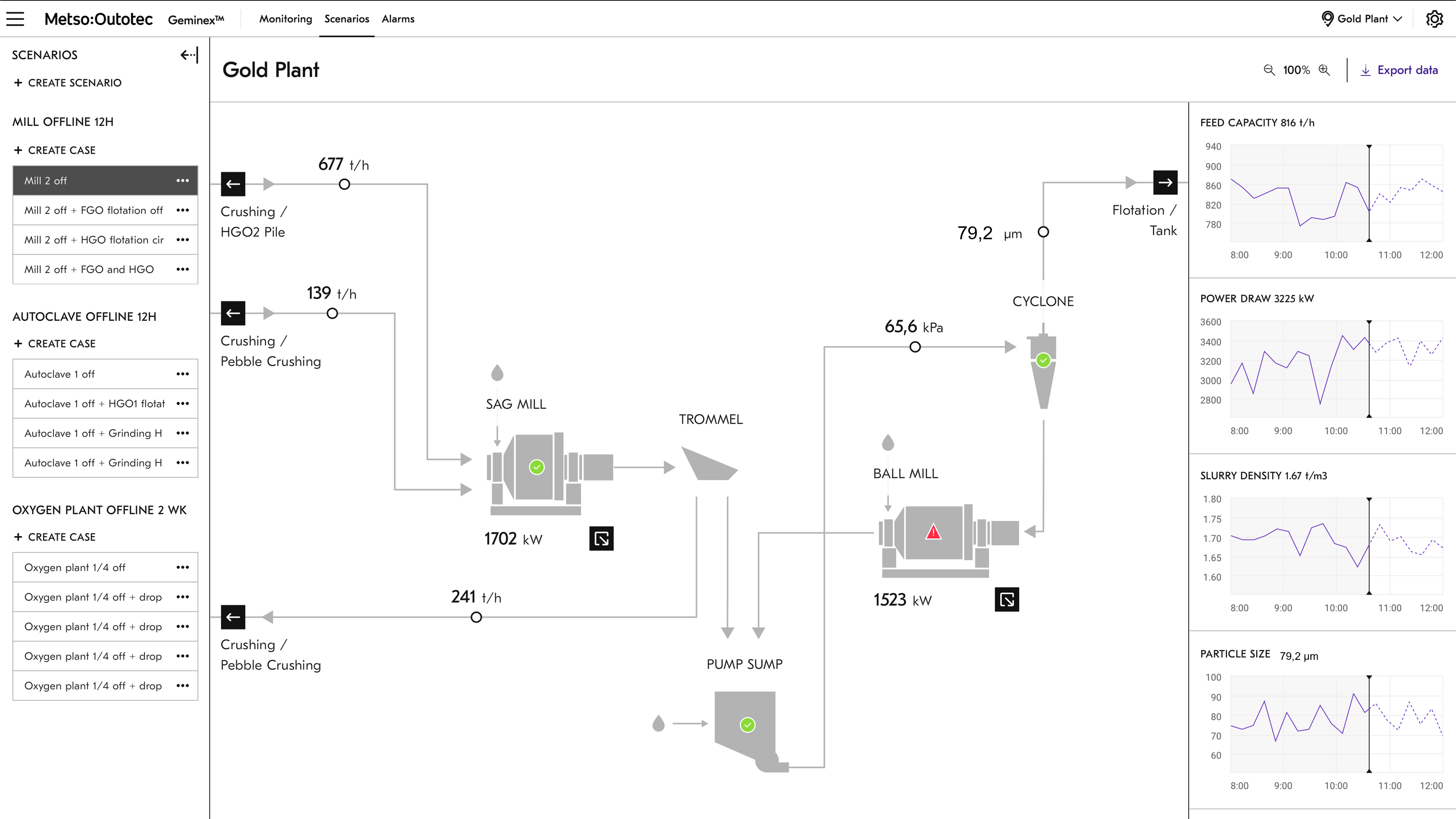

Digital twins are the most recent addition to this trend, offering the potential to revolutionize the game. Metso's metallurgical digital twin, Geminex™, supports the trend towards autonomous operations by integrating data from various databases and systems used in mineral processing. This enables operators to better manage the variability in feed materials, metallurgical processes, and the overall environment.

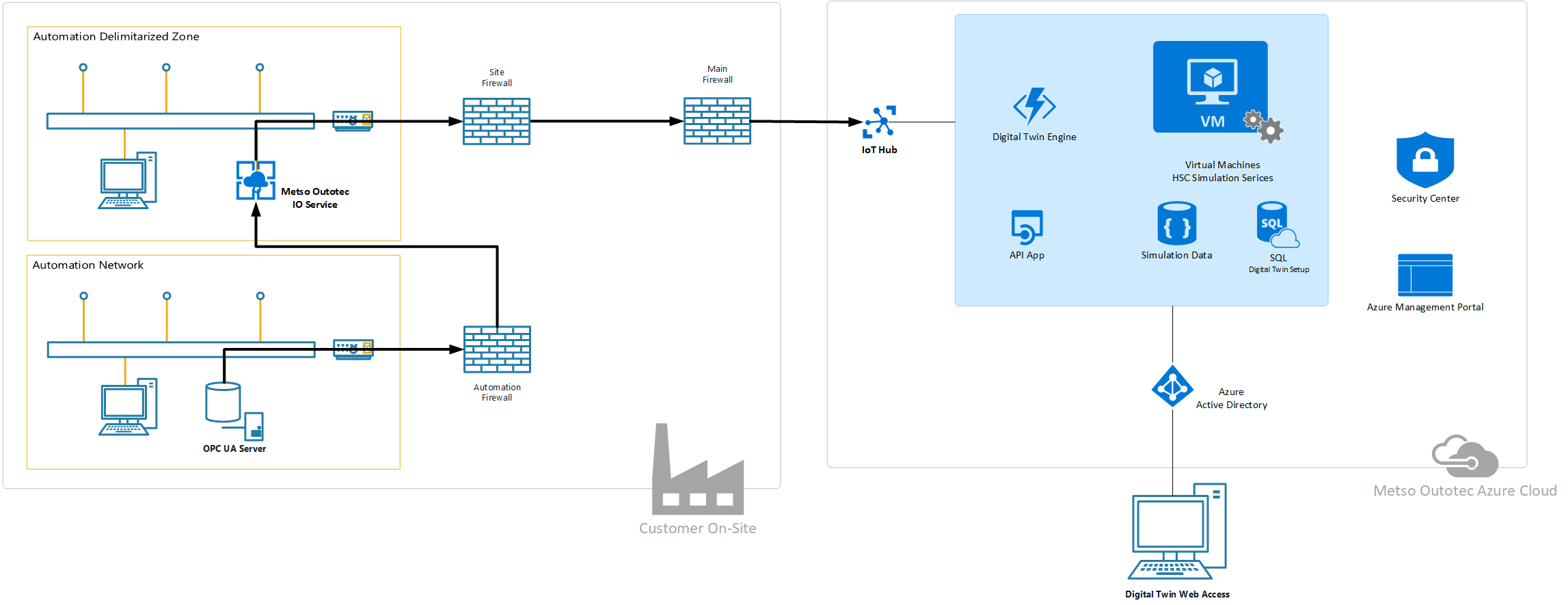

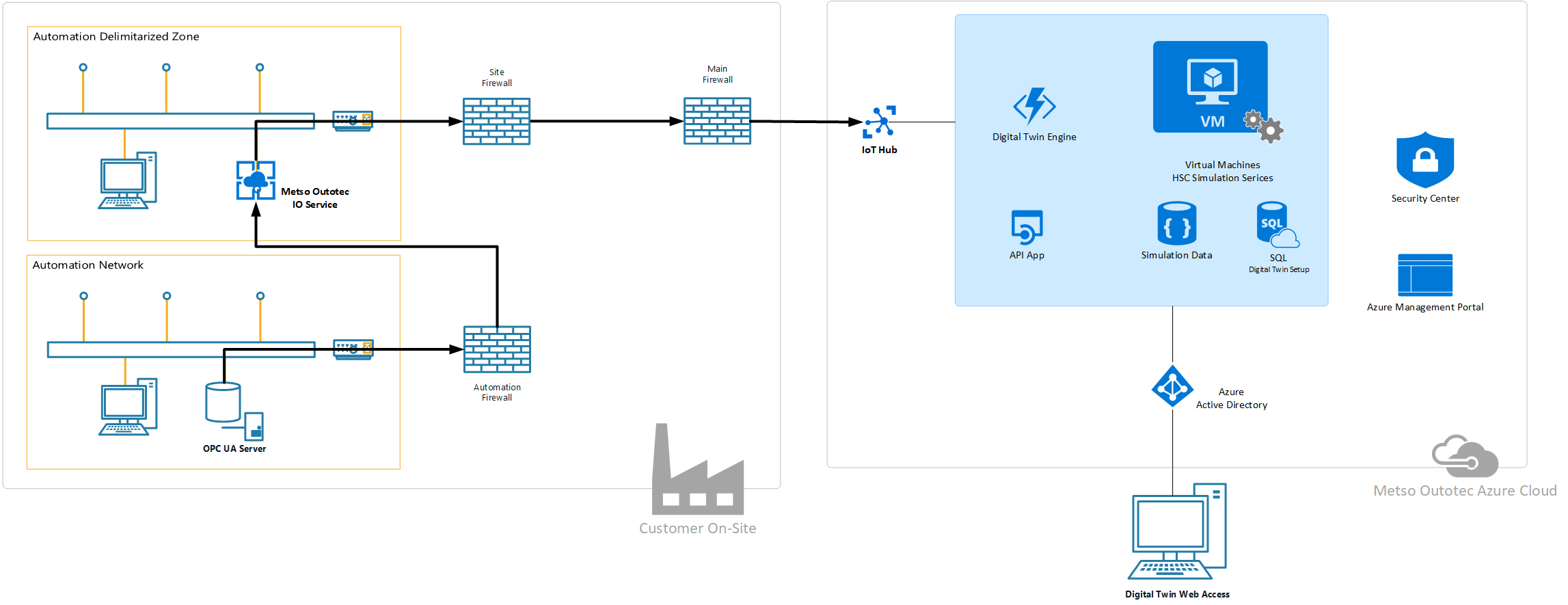

In the midst of this, cyber security has become a growing concern, with more and more business moving online. Cyber security issues are not just a direct threat to confidential data, but can also ruin relationships with customers or even place them in significant legal jeopardy. Thankfully, cyber security threats have been a discussion point since the initial development of Geminex™, and have been mitigated to the lowest level. This way, we can ensure our customers’ data is handled safely and securely.

Here at Metso, safety is our top priority and at the core of everything we do - and this includes in the digital space as well. We are committed to establishing a cyber secure connection between local data sources and cloud-based digital twin implementations, whilst ensuring protected access for on-site operators and corporate offices.

What is a metallurgical twin?

Digital twins have become increasingly important as they enable operators to make informed decisions in order to select the best outcomes, ultimately ensuring optimal results.

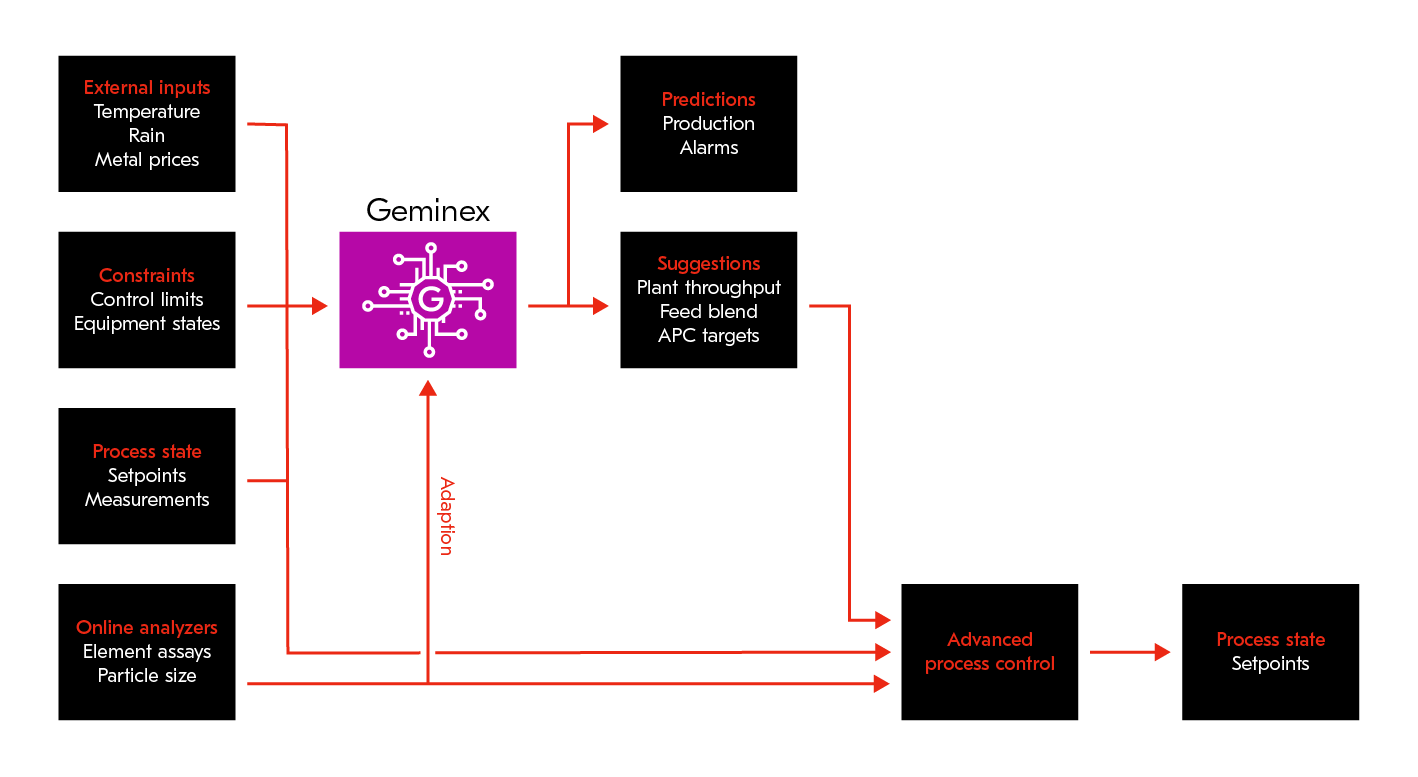

A metallurgical digital twin provides an unbiased process model by automating adaptation and learning from online sensors and process history data. The model is based on first-principle equations, equipment dimensions and flow sheets in dynamic mode. Thus, creating simulations of any process configuration and operating strategy before execution. This helps to mitigate risks related to environmental, financial and safety issues, leading to better decision-planning within the plant and resulting in better recovery and process optimization.

”Geminex™ allows for autonomy and overall optimization,” says Johanna Kortelainen, Simulation Specialist – Metso. ”What this offers can be very much utilized to see not only how different areas operate, but also how they can actually operate even better.”

The implementation of a metallurgical digital twin is typically split into phases, starting with the creation of a static model of the operation with the actual process flow sheet. The model is then converted into a dynamic model with equipment hold-ups to allow for time-dependent simulations. In the final phase, the simulation model is connected with live plant data for effective model adaptation.

Geminex™ is seamlessly integrated with APC process optimizers that seek the optimal process set points. For example, the varying feed ore, constraints, and equipment availabilities indicate varying regions for plant optimization. The digital twin predictions will give a set of alternative operating targets and find ways to further optimize for each process area APCs. Such as, in flotation, the control actions are made into froth speed, aeration, levels and reagent dosages.

“APC has a set of constraints, and what Geminex can do is either find the optimum targets within those areas or test what is actually conceivable within them,” says Johanna. “Essentially, in the case of flotation, Geminex is saying the process is capable of X recovery while maintaining Y grade. These targets are then given to the optimizer, which tries to drive the process towards the predicted optimum. Additionally, you could try to run the process outside of the set boundaries to see whether there's benefit in increasing your limits.”