Being a technology leader in providing plant and equipment solutions for alumina calcination, part of our mission at Metso Outotec is to provide our customers with integrated services that ensure reliability, maximum performance, and safe operation of their plants and process equipment. Our service portfolio is aimed at improving the OEE (Overall Equipment Efficiency) and provides support to customers to improve their performance with regards to availability, throughput, and product quality.

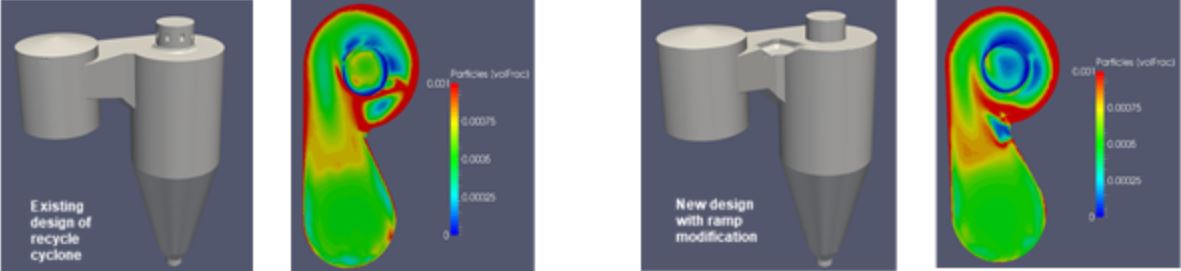

Our service portfolio includes equipment inspections, plant audits, CFD modeling as well as research and development, including lab and pilot plant facilities, providing troubleshooting and solution optimization. Our knowledge is based on years of expertise and experience, in conjunction with the development of key spare parts and maintenance-friendly equipment packages, we can perform modernizations and upgrades to boost the reliability of your plants. Our range of alumina calciner services is typically associated with shutdowns which are extremely challenging procedures for many customers, characterized by tight schedules to reduce production losses, high costs, and risks.

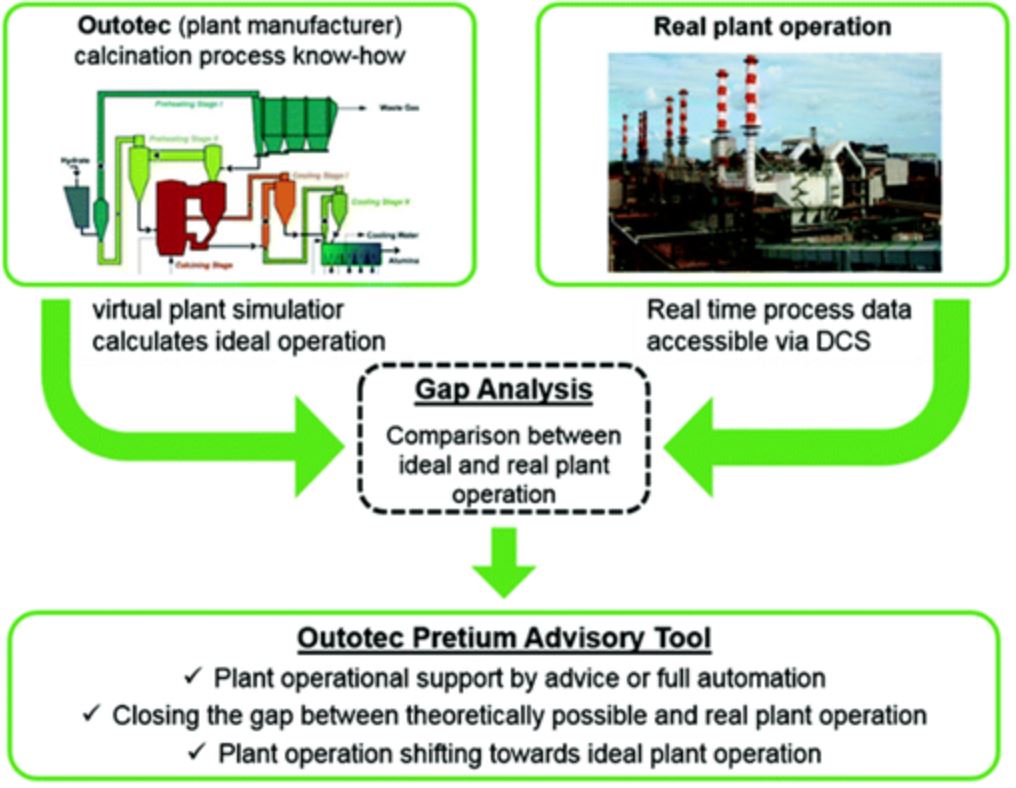

Our comprehensive shutdown planning and management procedures have advanced over decades of successful furnace shutdown services, greenfield plant installations, and brownfield modernizations, specifically for CFB calciners. We are also pioneers in the development of digital tools for the metals and mining sectors, our calciner optimizer digitization offering primarily targets the improvement of energy efficiency of calciner operations.

We view our customers as strategic partners. To strive to assist our customers to design the best maintenance practices and long term operation strategies. We recommend developing a comprehensive calciner roadmap in collaboration to ensure equipment and operational improvements, to prioritize and finally implement these measures with our specific service products and offerings. Our global presence and local operations enable world-class engineering, project delivery, and service for our customers. Our experts from a worldwide network of extensive technical, engineering, and operational capabilities. Safety is of utmost importance to us, our QEHS Management System defines the principles and elements by which we conduct our global business to protect employees and stakeholders, the public, company property, and the environment.

Equipment Inspections

Certain pieces of equipment are process critical for smooth calciner operations, such as the feed screw, preheat burner, discharge device, fluidized bed cooler, ESP, etc. Periodic inspections during the planned shut-downs, conducted by a Metso Outotec specialist, provide precise information about the condition of the equipment. The inspection reports summarize the equipment status and developments to provide maintenance, operational, and safety-related recommendations. This information is critical in maximizing operational capacity by minimizing unscheduled downtime and maximizing the possible campaign life. It also allows planning the requirements for the next shut-down as well as the operating expenses over the long run.

Plant Audits

Metso Outotec also applies process know-how to perform comprehensive calciner plant/process audits, to investigate bottlenecks, the potential for improved process performance, production or product (Alumina) quality, and the impact of raw material or fuel basis changes, etc. We value customer feedback to ensure continuous improvement and R&D activities as we strive to enhance equipment and designs. Continuous improvement includes the latest technologies as potential retrofit solutions.