While improper lubrication could cause a sudden failure overnight, contamination is a far more discrete condition that progressively leads to mill gear failure without any obvious symptoms. Indeed, contamination is to gear failures what high blood pressure is to heart attacks - a silent killer. And that silence could be deadly for your grining mill's gears. But just like there are ways to detect and control high blood pressure, there are also many ways to minimize gear contamination to benefit from the asset’s expected 25-year lifecycle when designed to the most stringent industry standards such as AGMA 6014 – Gear Power Rating for Cylindrical Shell and Trunnion Supported Equipment.

Types of contaminants

While anyone understands the definition of contamination, its occurrence is most often overlooked due to its sneaky nature. Despite the popular expression to “throw sand in the gears”, little attention is spent on monitoring and controlling the many different types of contaminants that could be categorized as solid or liquid.

Solids

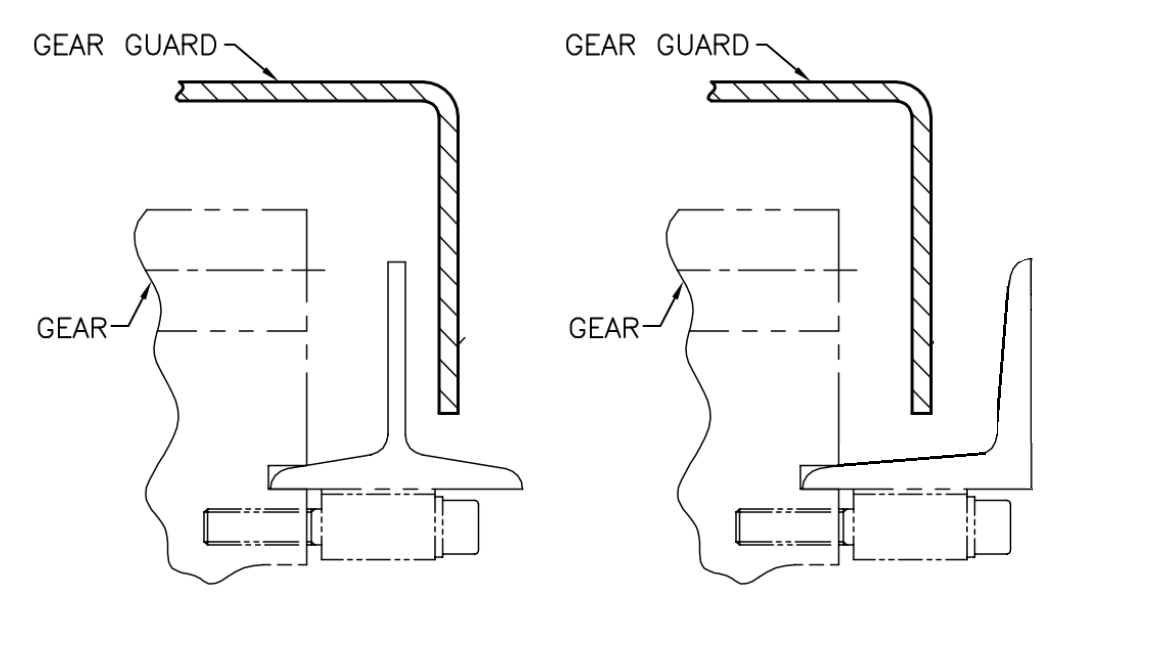

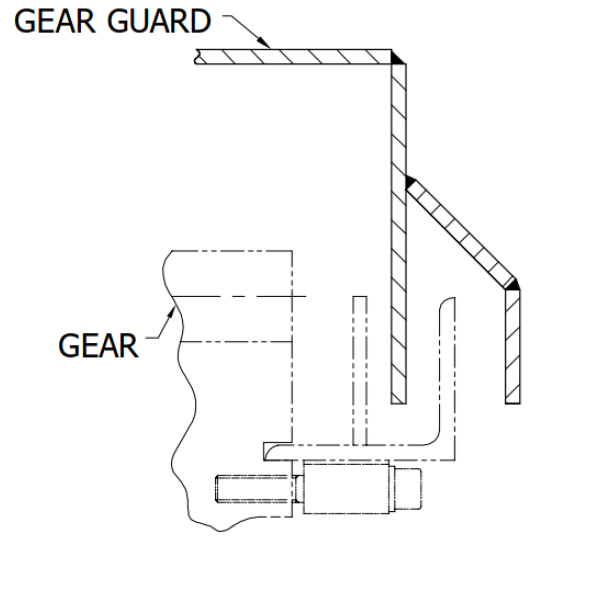

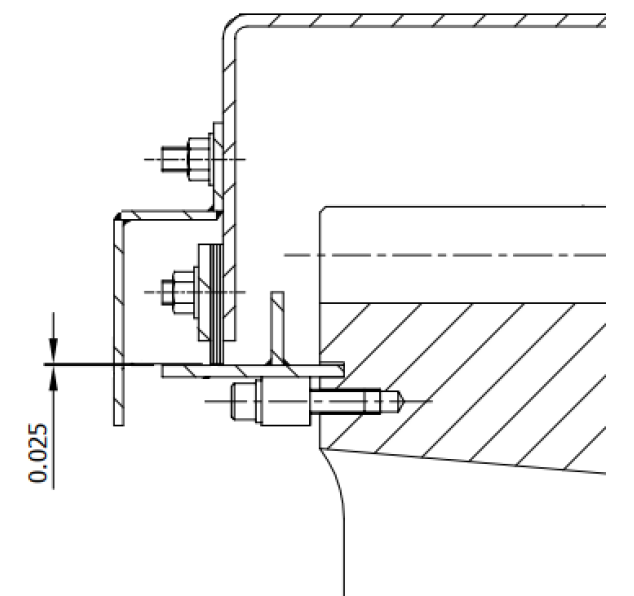

Solid contaminants, also referred to foreign materials, are finer particles that are either suspended matter such as dust infiltration or coarser particles such as dirt and debris that ingress from the surrounding harsh environment. Due to their relatively small size, these contaminants easily find their way through the mud and gear guards that do not always provide proper sealing in certain environments. Hence, the particles will tend to stick to the gear and pinion’s tacky lubricant and get caught through the gear mesh during operation, accelerating wear and reducing lifespan.

Dust infiltrations are very common in dry grinding applications such as cement plants where constant dust clouds are present within the plant. In wet grinding applications, dirt and debris accumulation occur from material transfer such as ore falling from the feed chute or from other equipment adjacent to the mill.