Kinetic flotation model: based on test work

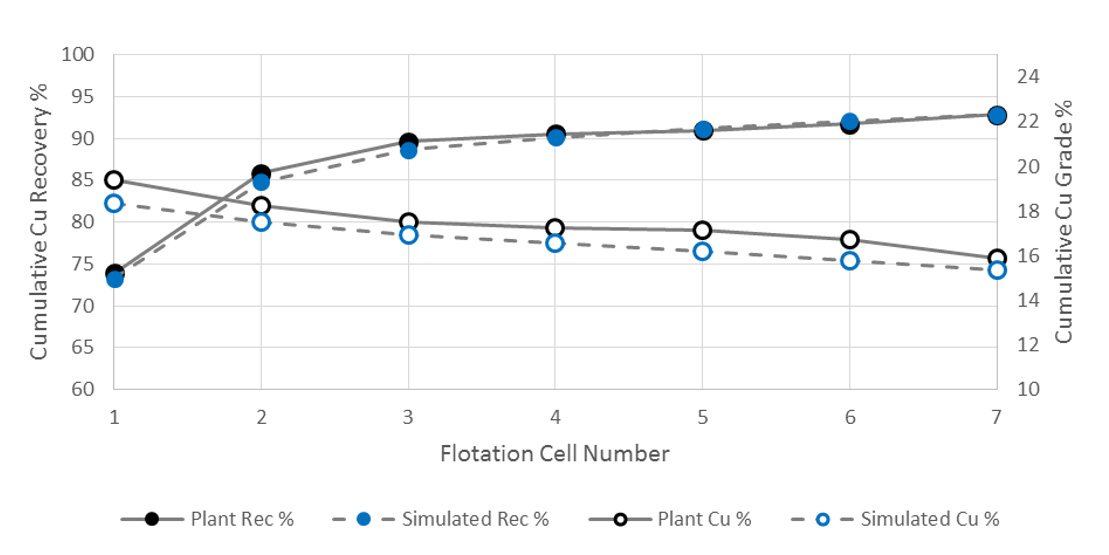

In the kinetic flotation model, mineral recoveries are calculated based on the flotation cell residence times and the particle flotation rate constants. For example, Outotec HSC Chemistry® Sim flowsheet simulation software utilizes a unique property based modeling approach, which means that the solids feed material is based on minerals that are always defined as particles, and have properties such as size fraction, solids density, floatability, etc. Thus, the material is set up similarly to real slurry streams and the chemical composition is calculated based on its particles and mineral composition.

The flotation kinetic model parameters are derived from continuous plant sampling data or from batch laboratory tests. Figure 1 shows the Outotec GTK LabCell laboratory flotation machine for batch testing.

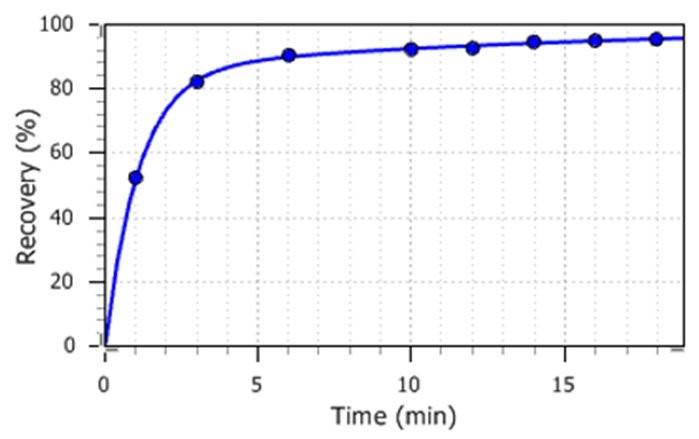

The outcome of a kinetic batch flotation test is a series of cumulative recoveries of assayed elements as a function of time. The element recoveries are further converted to mineral recoveries. The benefit of the conversion is that the gangue kinetics can be calculated and the total mass recovery is obtained from the mineral recoveries. The cumulative kinetic data is model fitted to set up equations based on the flotation kinetic rate constants k min-1. Both the element-to-mineral conversion and the kinetics model fitting tools are included in the HSC Chemistry® software.