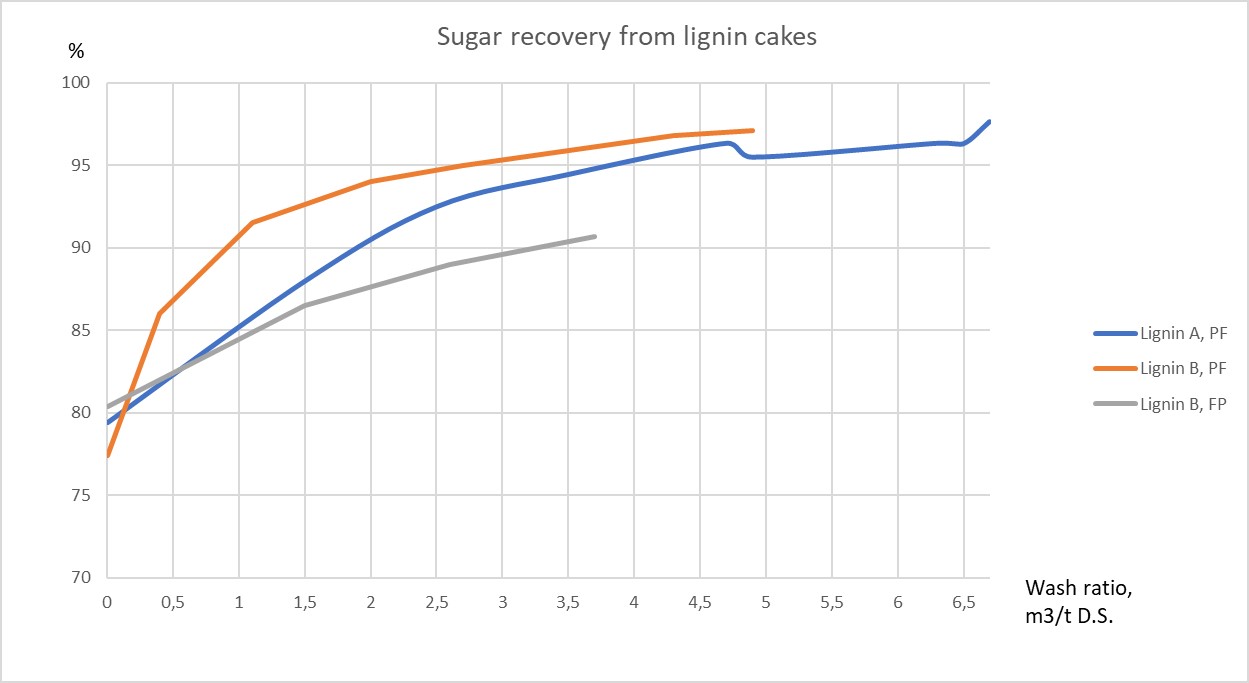

As seen in the chart above, the sugar recovery without cake washing is around 80 % depending on the residual moisture content of the cake. When cake washing is included, the sugar recovery increases significantly with the Larox® PF technology already with lower wash liquid consumption. When comparing lignin B, a wash ratio of around 1 m3/t D.S. is sufficient for >90 % sugar recovery with Larox® PF. With the conventional filter press technology, on the other hand, a wash ratio of around 3.5 m3/t D.S. is needed to achieve as good results. With a wash ratio of 3.5 m3/t D.S. results in a sugar recovery of 95 % with the Larox® PF filter.

Another way to estimate the washing efficiency between filtration technologies is to analyze the sugar content of the filtrate during filtration cycle. This can be done with Brix measurement or by using chromatography measurement. It has been seen that with the Larox® PF filtration technology, the sugar content in the filtrate stays relatively constant all through the washing step and then drops rapidly indicating that the wash has been completed. This indicates that wash liquid has evenly replaced the sugar solution in the cake over time.

With the conventional filter press technology, the sugar content value in filtrate drops quickly after the washing step is started. This indicates that the wash liquid is not washing the cake evenly and is channeling through the cake.

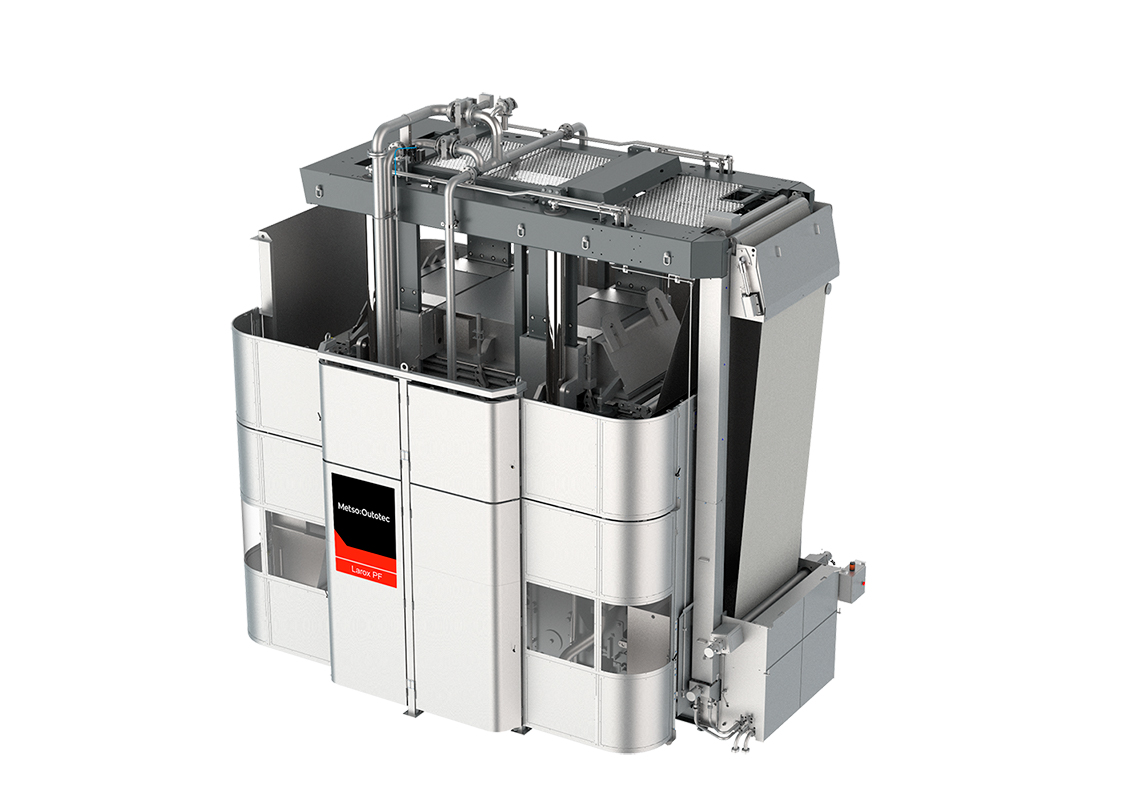

Moving into full scale plants

It must be kept in mind that the presented results are achieved with test units with small surface area. When moving into full scale plant unit sizes, the differences will be even bigger.

The horizontal plate alignment ensures that the Larox® PF filter has even cake washing regardless of the plate size. With conventional filter presses, as the plate area increases, the channeling effect will remain present and impact the washing result over the whole area of the cake and diluting the sugar concentration in the liquid phase.