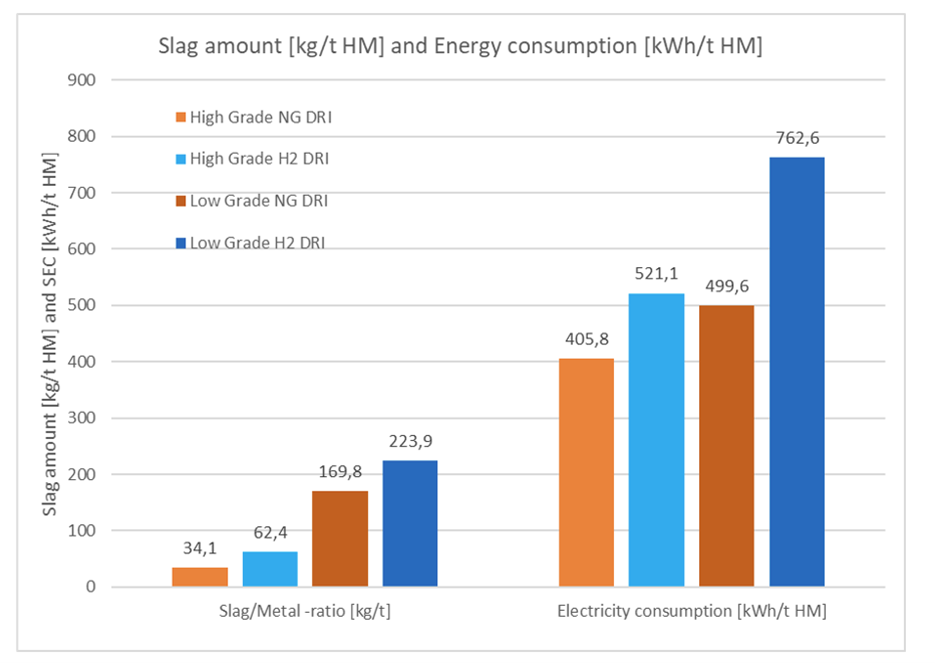

Figure 3 illustrates the amount of slag and required energy for various feed materials. We have carefully evaluated how the process behaves in different operating environments, and what is an optimal solution for a steel mill and for producing independently granulated hot metal for sale. The circular economy options for the produced slag are under research, as slag produced with an electric arc furnace cannot replace blast furnace slag in cement production due to completely different slag chemistry and high share of non-reacting FeO in it. On the contrary, the slag produced with the DRI smelting furnace could substitute the blast furnace slag and yield to significant CO2 emission savings in the cement industry. This is one of the major ESF technology benefits that should be considered when steel producers are making decisions between EAF and ESF technologies replacing the current blast furnaces.

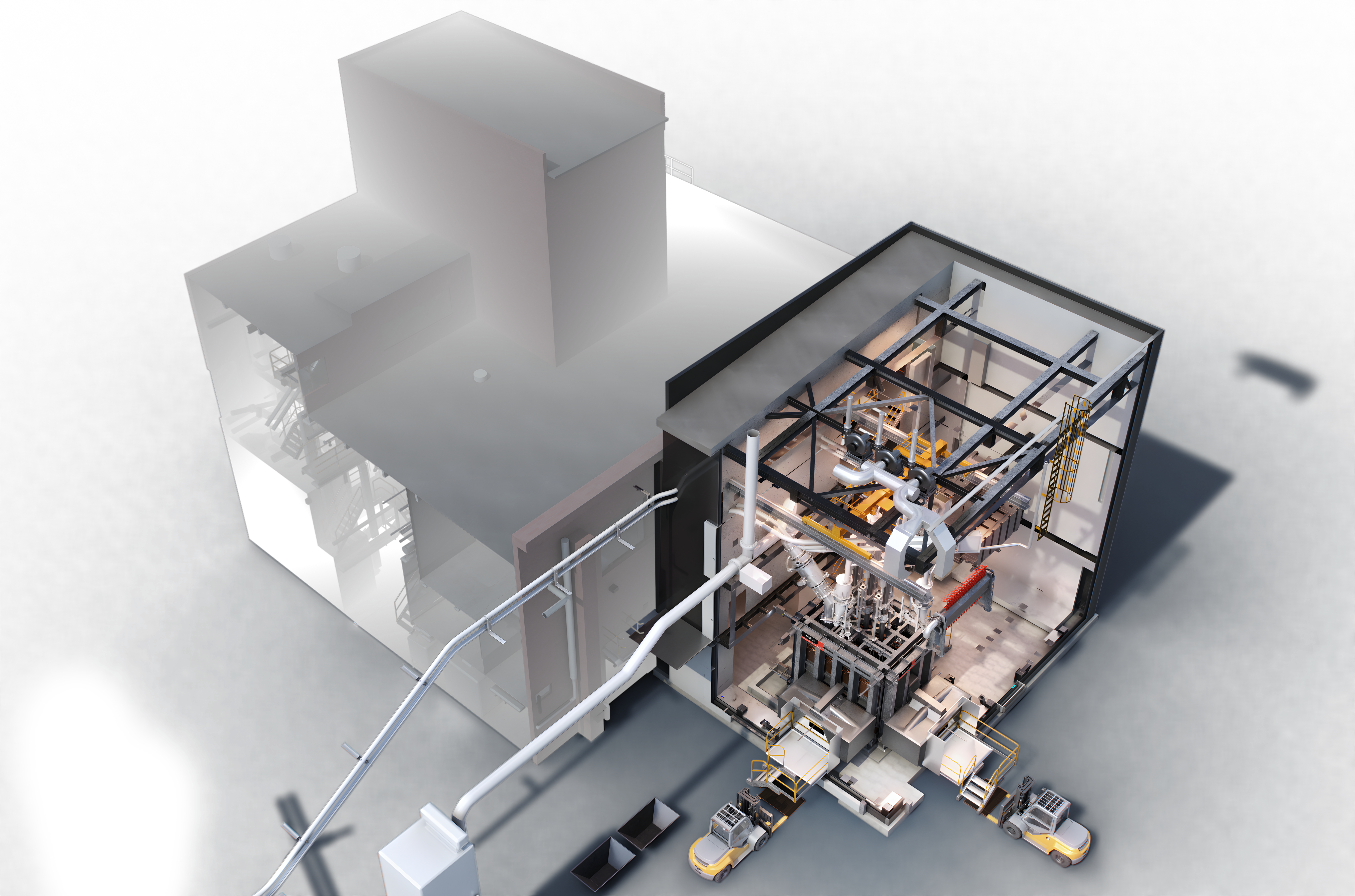

Metso did a pilot study on the carburization of natural gas reduced DRI with a modified AC furnace. The focus of the pilot campaign was to study the use of a bank for carburization (figure 4). In the campaign, the carbon content of the produced hot metal could be increased to over 3% which was the target value. When the campaign was conducted in March 2023, hydrogen reduced DRI was not available in sufficiently large quantities. Nevertheless, the metallurgical behavior of the process could be studied with Metso’s existing circular furnace. The new, larger rectangular pilot furnace being built at the Pori Research Center will enable further studies and technology development (see figure 1). This new 3-in-line furnace is a smaller version of the industrial 6-in-line furnace.

The name of the pilot furnace comes directly from the shape of its electrode assembly. The dimensions of the pilot furnace are roughly 3x2m and the feed rate is 1000 kg/h. The most important technical features are the same in the pilot and the industrial scale. The equipment will be used for Metso’s own development work, but also for testing different feed materials for customer needs.