MODIFICATION OF THE TAMANO FLASH SMELTING FURNACE (FSF)CONCENTRATE BURNER

Previously, the Tamano FSF concentrate burner faced the following problems.

- The burner inspection hole layout did not allow for the cleaning and removal of buildup, which made inspections difficult.

- Thorough removal of the buildup was not easy for reason (1.) above, and we were forced to continue operation with a poor concentrate reaction.

- The thermal deformation of the platform structure in the concentrate burner area meant that the burner nozzle was prone to misalignment.

- The misalignment explained in (3.) helped the buildup to grow on the concentrate burner jacket and this led to an uneven concentrate reaction.

- Maintaining the proper function of the burner’s eccentricity detector and position adjuster was not easy, and the position adjustment was a time-consuming task.

We therefore made modifications such as changing the inspection hole layout. The layout was changed to a design that allowed the thorough and quick removal of buildup. In addition, we modified and replaced the supporting structure and also replaced the adjustment system consisting of a jack and a position adjustment device with a system fixed onto a welded plate to maintain the adjusted clearance for an extended period of time.

PEFORMANCE OF THE MODIFIED CONCENTRATE BURNER

The modification reduced the inspection frequency from an average of 3.1 times/day to 2.5 times/day, thereby lowering the operating load. The time required on inspections to reduce the rate of the concentrate charge by 15% was shortened by 55 hours/year and the dust generation rate decreased from 8.1% to 5.8%. The modification thus contributed to the stabilization of the reaction in the concentrate burner.

MODIFICATION OF THE TAMANO FSF UPTAKE SHAFT

Previously, the Tamano uptake shaft faced the following problems.

- Accretions grew on the uptake shaft’s inner surface because of the plate cooling element of the off-gas from the FSF, and required removal by scraping into the settler.

- The concentrate feed rate had to be reduced by approximately 30% (for approximately 4 hours at a frequency of once a week) during the abovementioned removal, and this operation represented a loss of productivity.

- The replacement of the plate cooling element was required at maintenance shutdowns (every 2 years), which meant that the repair cost was considerable.

- The abovementioned factor (iii) did not allow a longer shutdown interval.

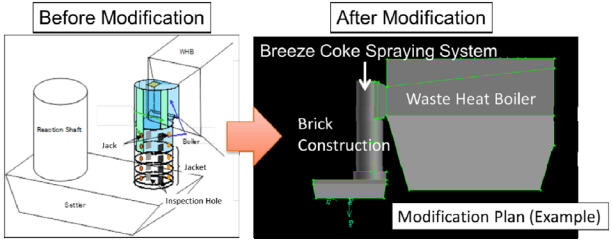

To solve the abovementioned problems, we changed the uptake shaft construction from a cylindrical plate cooling element design and a boiler to a refractory construction (Fig. 2). We also added a breeze coke spraying system to the top of the uptake shaft to reduce (deoxidize) the accretions that had stuck to and grown on the uptake shaft wall through coke spraying.