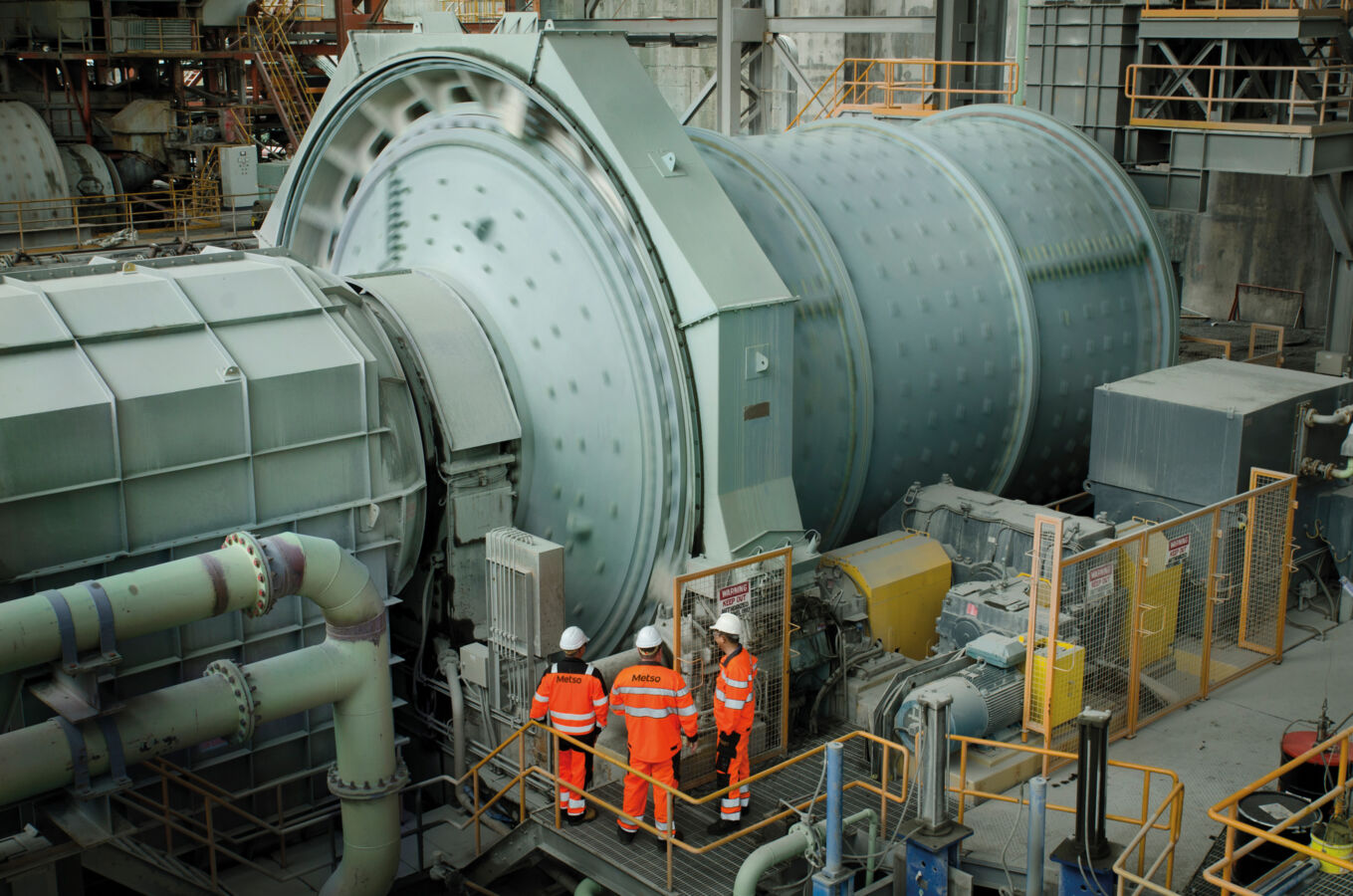

In my role as a technician for Metso, I have spent over ten years working in and around grinding mills. I noticed some areas of the mill often get the most attention from maintenance teams such as the gear, pinions and liners. However, other components can also be critical to maintaining the uptime of the mill. One area that is often overlooked is the seals that protect the bearings and the bearing housing.

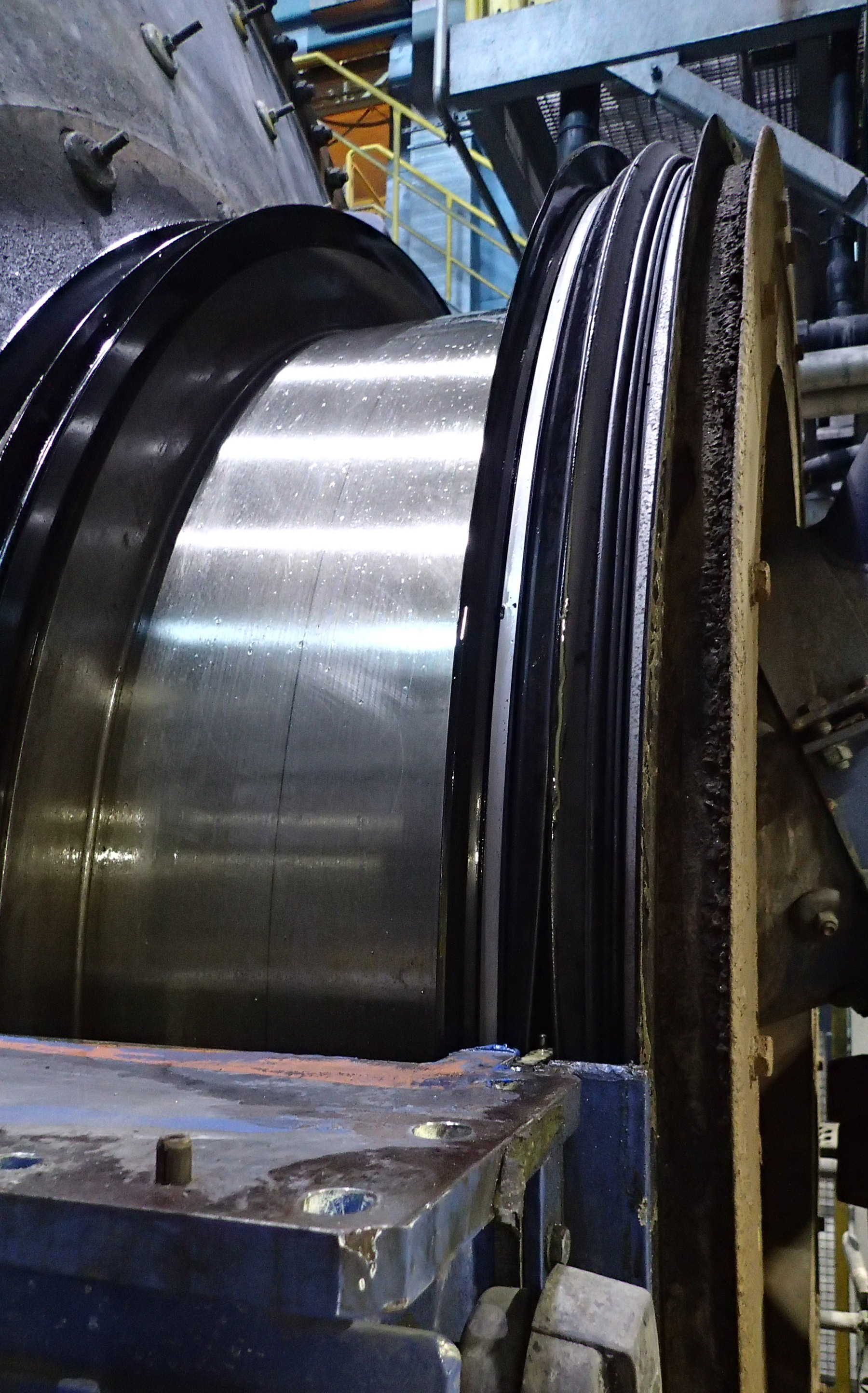

I once came across a mill which had an accumulation of 10 cm of slurry in the bearing housing, clearly posing a serious risk of damage to their once maintenance-free bearing, due to the slurry contaminating the oil. This risk could easily have been avoided with timely inspections and correct maintenance of the mill’s bearing seals. Read on to learn about timely sealing inspections and the three things to consider when it comes to the planning and execution of audits.