As water experts warn of a serious global water shortage resulting from climate change, sustainable water management is critical. Mining companies are on the front line of water security risks. The mining industry uses water for a variety of purposes, including mineral processing, dust suppression, slurry transport and storage, extraction processes, and site usage. In most mining operations, operators extract water from groundwater, streams, rivers, lakes, or through commercial water service suppliers. To make things even more challenging, some mining sites are located in areas where water is already scarce.

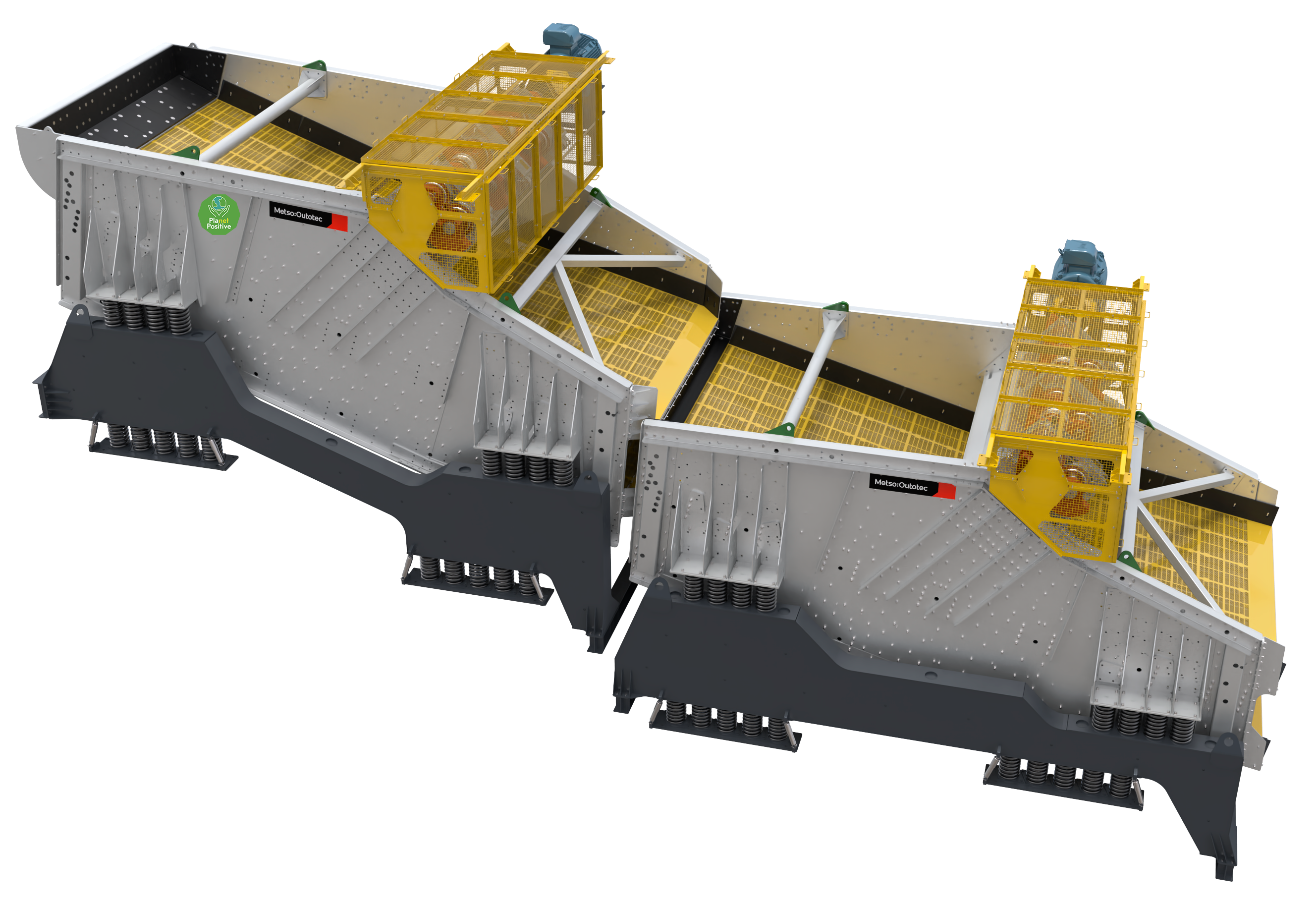

The business is well aware of the need for more sustainable use of water and many companies cooperate with suppliers to find new efficient technologies. While the expected details and efficiencies vary greatly depending on the technicalities of the industry process, the complexity of the design, and the geographic location, there are a few areas that have a great impact when it comes to optimizing water management. Screening is one of them.

Managing high-moisture screening

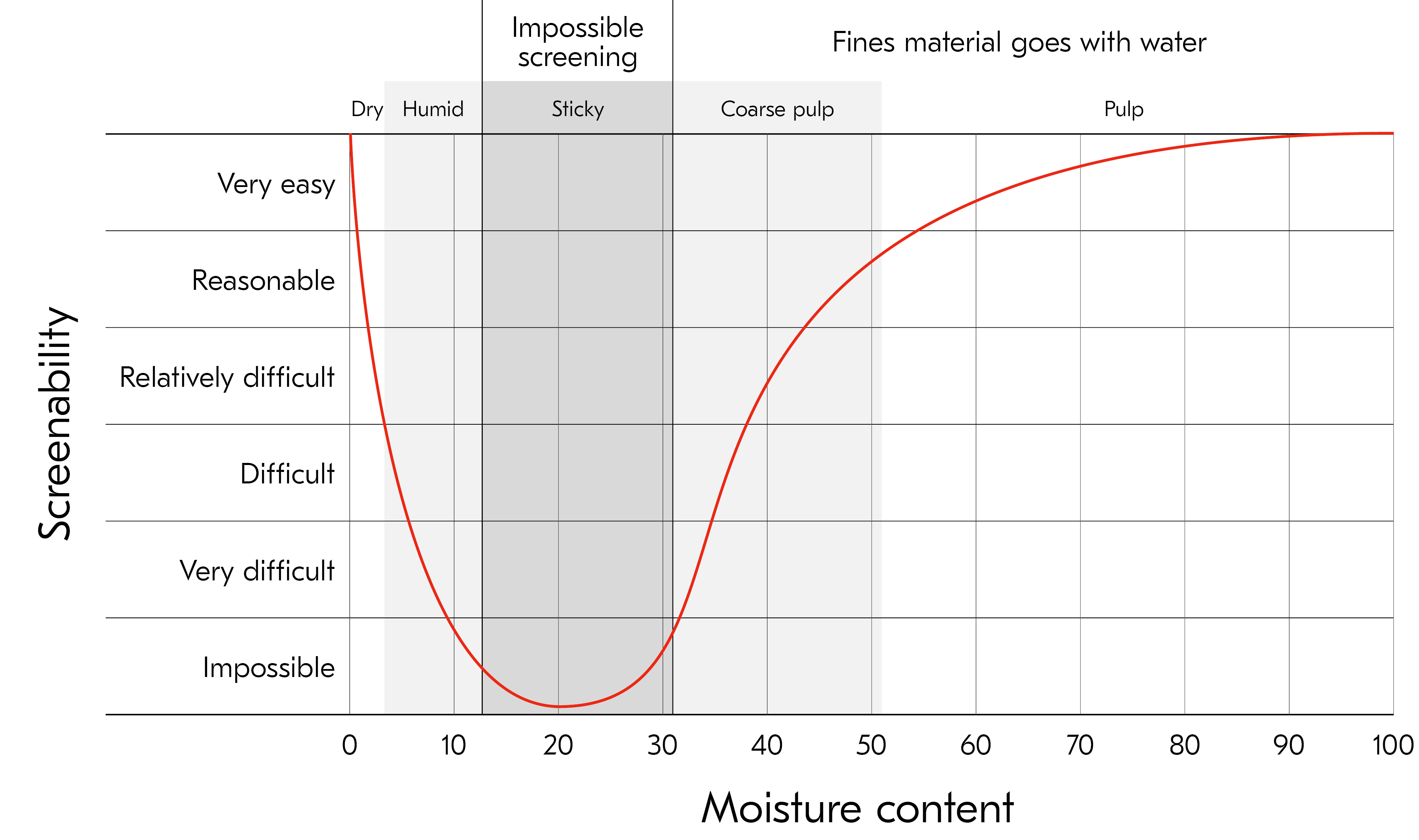

Many mining sites are located in regions with humidity or periods of intense rainfall. High-moisture screening is often a big challenge and it easily results in blinding, if water is not added in the process. However, when adding water is not an option, the need for a solution that provides efficient dry-screening of high-moisture ore, becomes crucial.