In the beginning plant sizes were quite small: the first pellet plants had a machine width of as little as 2.5 meters and annual capacities in the range of one million tons. In order to respond to the growing demand for pellets and to reduce investment and operational costs, machine widths grew to four meters and reaction areas to 818 m². Today, the highest capacity plants can produce more than nine million tons of pellets a year in a single furnace. The last three-meter plant, built by Metso Outotec in 1976 for Peña Colorada in Mexico, remains in operation to this day.

In recent years we have seen increased demand for plants with smaller capacities, particularly in India and China. The specific cost per ton of pellets increases with smaller plant sizes, and in terms of capital expenditure, engineering and project management represent a larger proportion of the total cost.

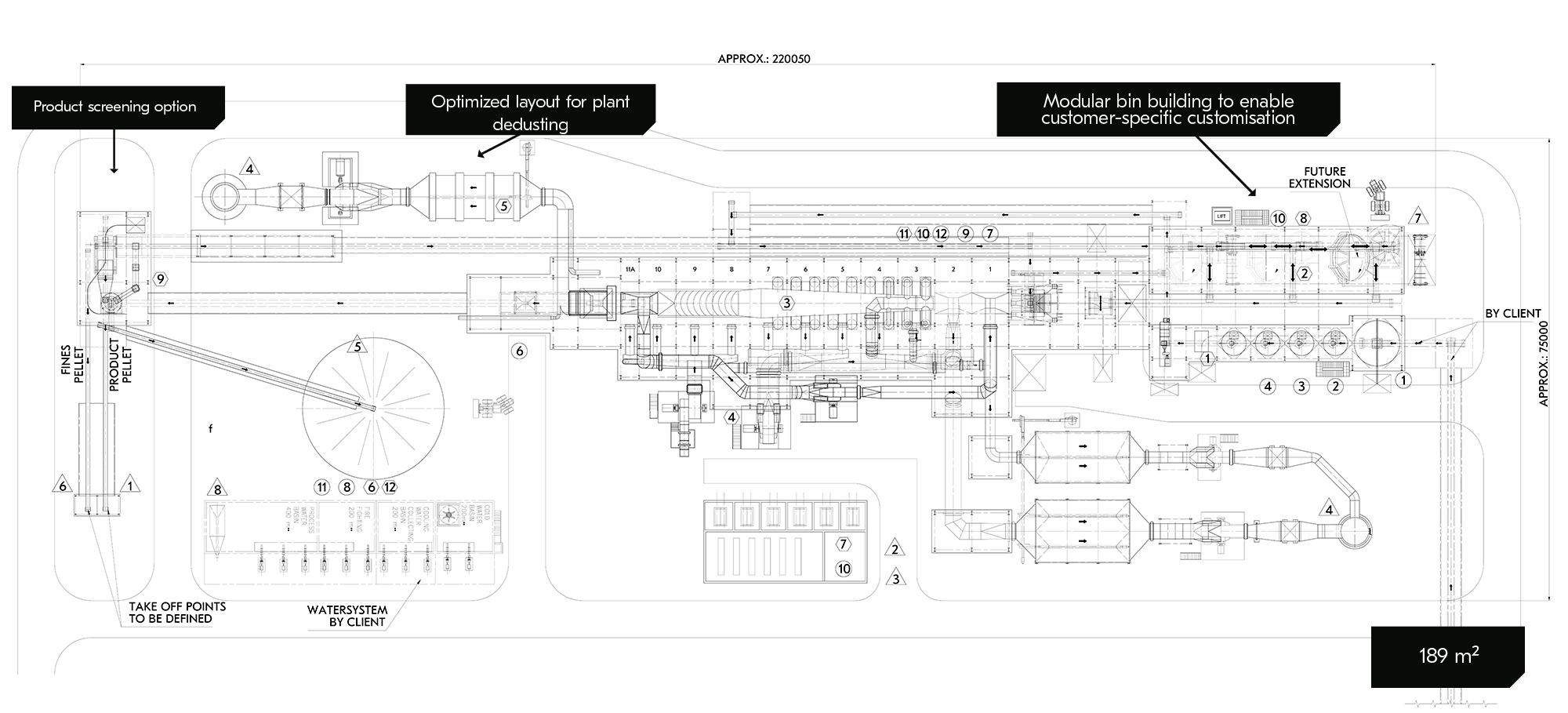

In response to this development we have invested heavily in optimizing our design, engineering, and project execution procedures as well as our supply base. As a result of these efforts we can now offer competitive pellet plants that have a smaller footprint and production capacity while still incorporating all the process features of the world’s biggest and most efficient plants.

The main features of our Compact-sized Pellet Plant offering are:

-

highly standardized engineering

-

optimized layout

-

modular and flexible configuration

-

minimized CAPEX and delivery time

Our compact pellet plants are available in the following standard sizes and corresponding capacities:

-

Size: 189 m2 Capacity: 1.20 - 1.50 Mtpy

-

Size: 288 m2 Capacity: 1.75 - 2.30 Mtpy

-

Size: 315 m2 Capacity: 2.00 - 2.60 Mtpy