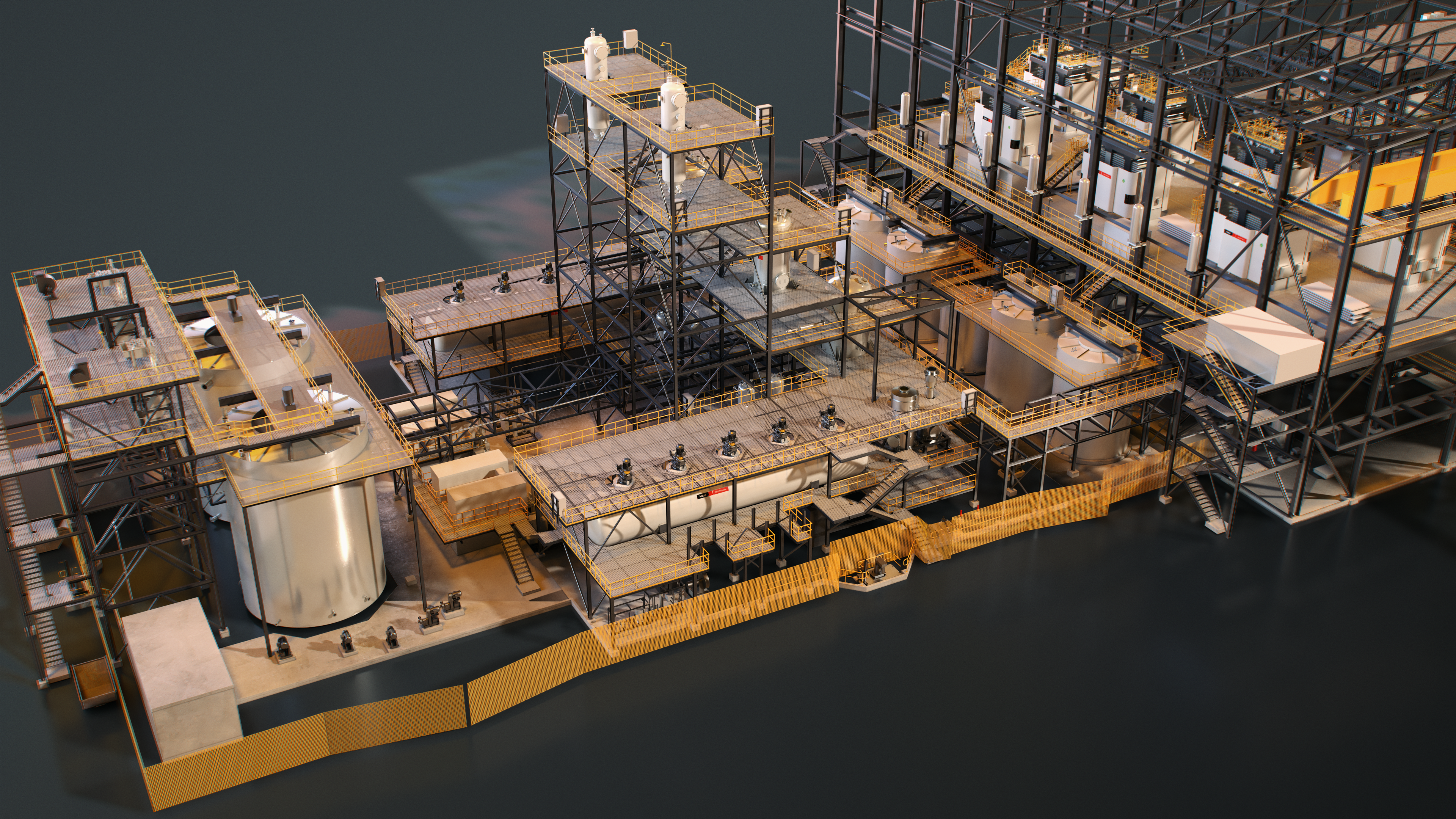

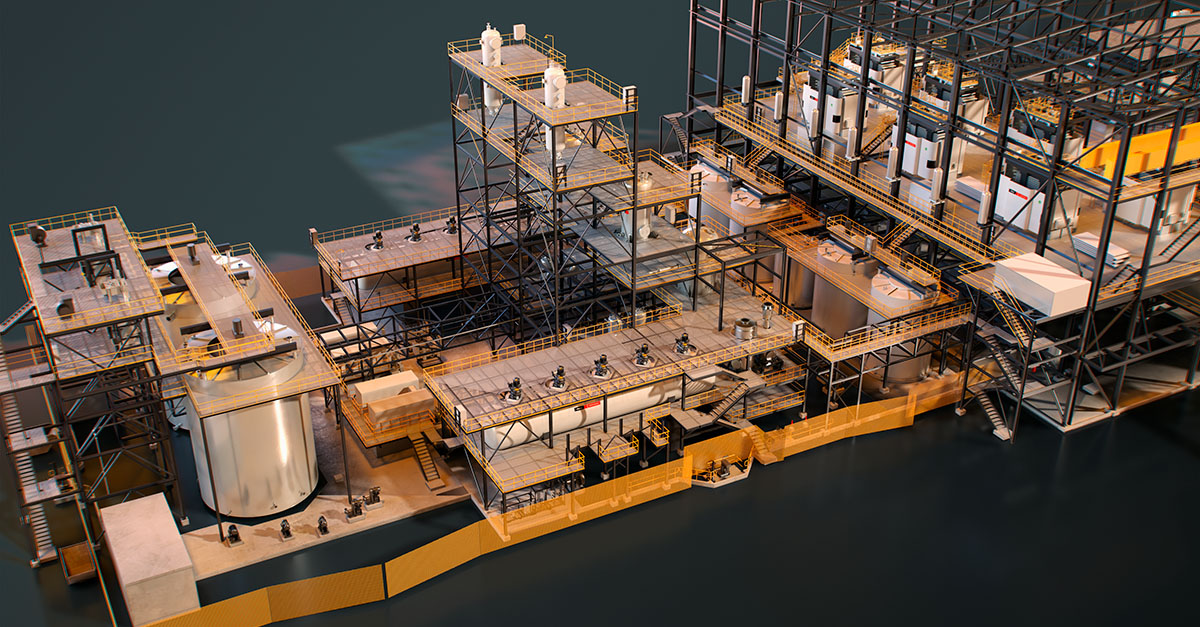

We have carried out years of extensive R&D on the alkaline leach process concept for lithium extraction from beta-spodumene and have introduced the Metso Lithium Hydroxide Process, a proprietary hydrometallurgical technology for refining spodumene concentrates. It is a direct leach process offering a sulfate and acid-free method to produce battery-grade lithium hydroxide monohydrate from spodumene concentrates. The process is environmentally sustainable as the main mineral residue “Analcime sand” is inert and readily neutralized. Additionally, the alkaline leach concept is currently under extensive development to cover also other hard rock lithium minerals like petalite, zinnwaldite and lepidolite.

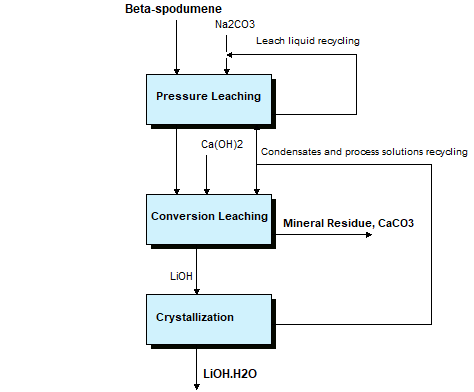

The Metso alkaline leach concept is based on a two-step process. Lithium is first extracted from the silicate minerals in pressure leaching. The reactions involve formation of an intermediate lithium compound and residual analcime mineral (NaAlSi2O6·H2O) as the main components. In the following conversion process step, lithium is solubilized, producing lithium rich solution and solid mineral residue which can be effectively separated in downstream pressure filtration step, including efficient washing. The alkaline processing milieu ensures selective extraction of lithium and very low solubilities of all the main impurity elements and compounds, including Fe, Al, Mg, Ca, B, and P. Overall, the lithium recovery from concentrate to dewatered and washed residue, typically exceeds 90%.