Mining companies are making significant investments in studying ways to improve the security and safety of tailings depositions. Several sites have started separating acid-generating material from the bulk of their tailings in order to significantly reduce the volume of tailings that require ongoing management and to create a more environmentally sustainable tailings storage facility (TSF).

In more arid locations, paste deposition and beach disposal have proven to be effective ways to increase water recovery and reduce risk in the tailings storage area. Some sites have progressed even further to dry stacking of filtered tailings.

A holistic view to helps identify performance improvements

Thickeners are recognized as one of the more cost-effective technologies for recovering water from tailings streams. Significant energy savings can be achieved by maximizing the recovery of water close to the mill. In addition, a higher density of tailings deposited in the dam tends to reduce the footprint and produce a more stable tailings deposit.

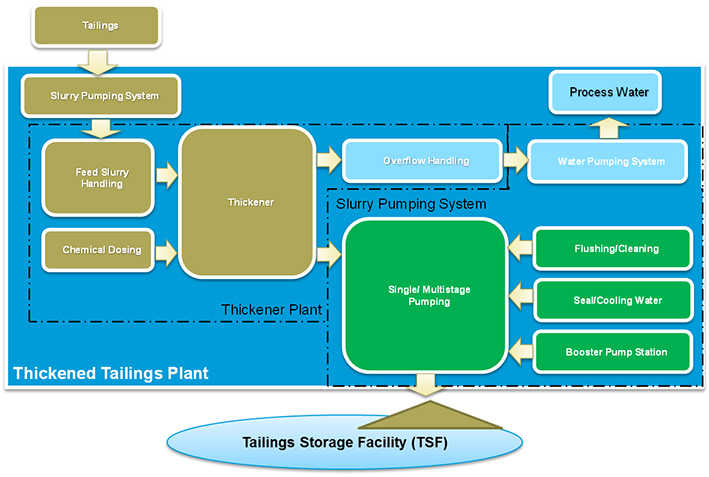

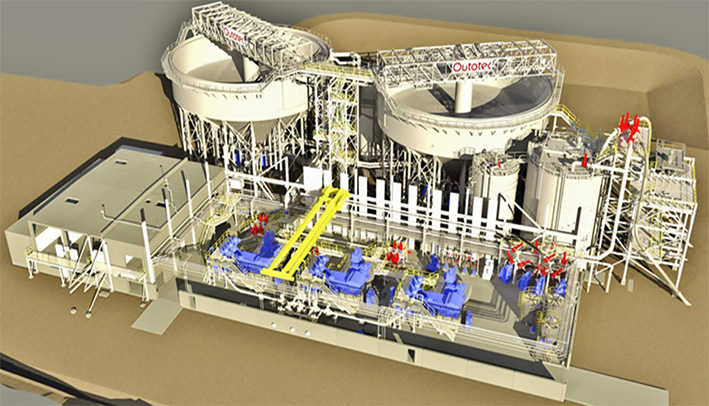

When considering a thickened tailings solution, there is the question of whether the technology to thicken tailings should be located in the thickener as a piece of equipment, or whether a complete solution is required to achieve the best performance. We typically view the components required to thicken tailings in isolation rather than considering them as a complete plant comprising a thickener, pumping system, automation systems, and the necessary ancillary equipment or systems required for operation (see Figure 2).

Because all these components interact with one another, in order to identify how performance can be optimized it is necessary to look at the whole system, rather than the thickener in isolation. As the thickener produces higher degrees of separation, the underflow increases in viscosity, which in turn leads to the high frictional losses that require higher discharge pressures to pump thickened tailings to the final deposition point. Optimizing the performance and cost of a thickener plant – whether it is a self-contained plant that is separate from the main processing facility, or part of the mill – is becoming a challenge as we increase water recovery with compact equipment, lower safety factors, and increasingly simplified testing campaigns.