Enhancing flotation circuit performance for inaccessible ores

Beneficiation plants grappling with inaccessible ores face unique challenges in optimizing flotation circuit performance. Here is a range of useful tips to address these challenges and improve results from existing flotation circuits.

Ore characterization: Ore characterization tools, including mineral liberation analysis and scanning electron microscopy, provide operators to comprehensively understand inaccessible ore mineralogy.

Reagent optimization: This allows mining professionals to fine-tune reagent formulations. By evaluating different reagent types and dosages, operators can achieve optimal selectivity, improving the recovery of valuable minerals while minimizing the impact on gangue minerals.

Grind size optimization: Grinding solutions contribute to the improved liberation of minerals in inaccessible ores. Tailoring the grind size optimizes the flotation process by enhancing mineral exposure and facilitating more effective separation in the flotation cells.

Froth management: Froth management strategies, incorporating advanced froth formulations and dosage control, enhance froth stability and selectivity. This results in improved flotation performance, especially in challenging scenarios presented by inaccessible ores.

Automation and process control: Process control and automation technologies ensure real-time monitoring and adjustment of flotation circuit parameters. This enhances stability, minimizes variations, and optimizes overall performance in response to the dynamic nature of inaccessible ores.

Sustainable water solutions: Water recycling and conservation through innovative solutions, addressing the water scarcity issues often associated with mining operations. Implementing efficient water management practices contributes to both environmental sustainability and operational cost reduction.

Sensor technologies: The incorporation of sensor technologies, such as online particle size analyzers and mineral analyzers, enables real-time data collection. This data-driven approach facilitates quick and informed decision-making, ensuring optimal flotation circuit adjustments based on the ore's changing characteristics.

Continuous improvement programs: Regular monitoring, data analysis, and optimization efforts are integral to ensuring that flotation circuits remain adaptable to variations in inaccessible ore characteristics and operating conditions.

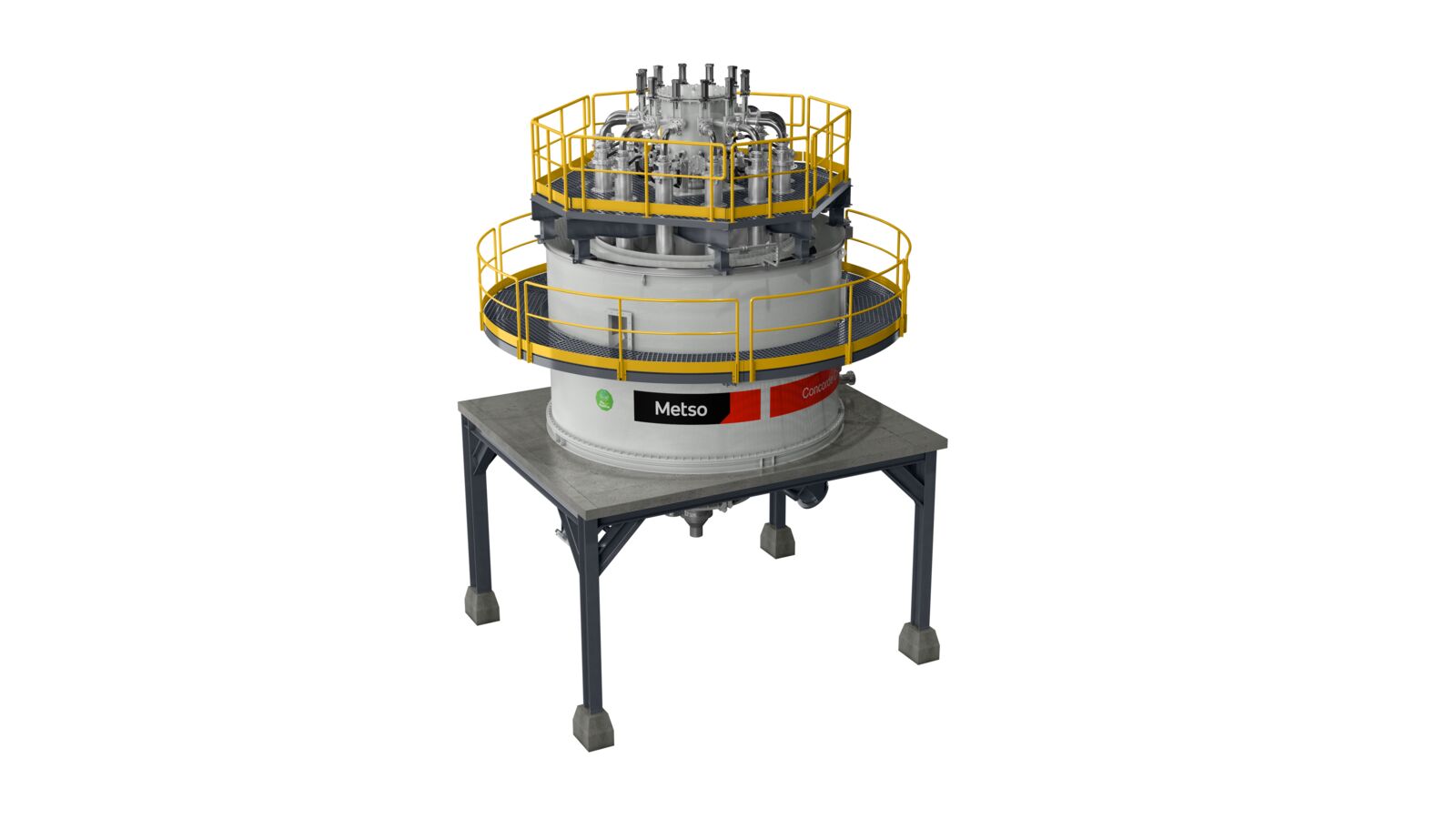

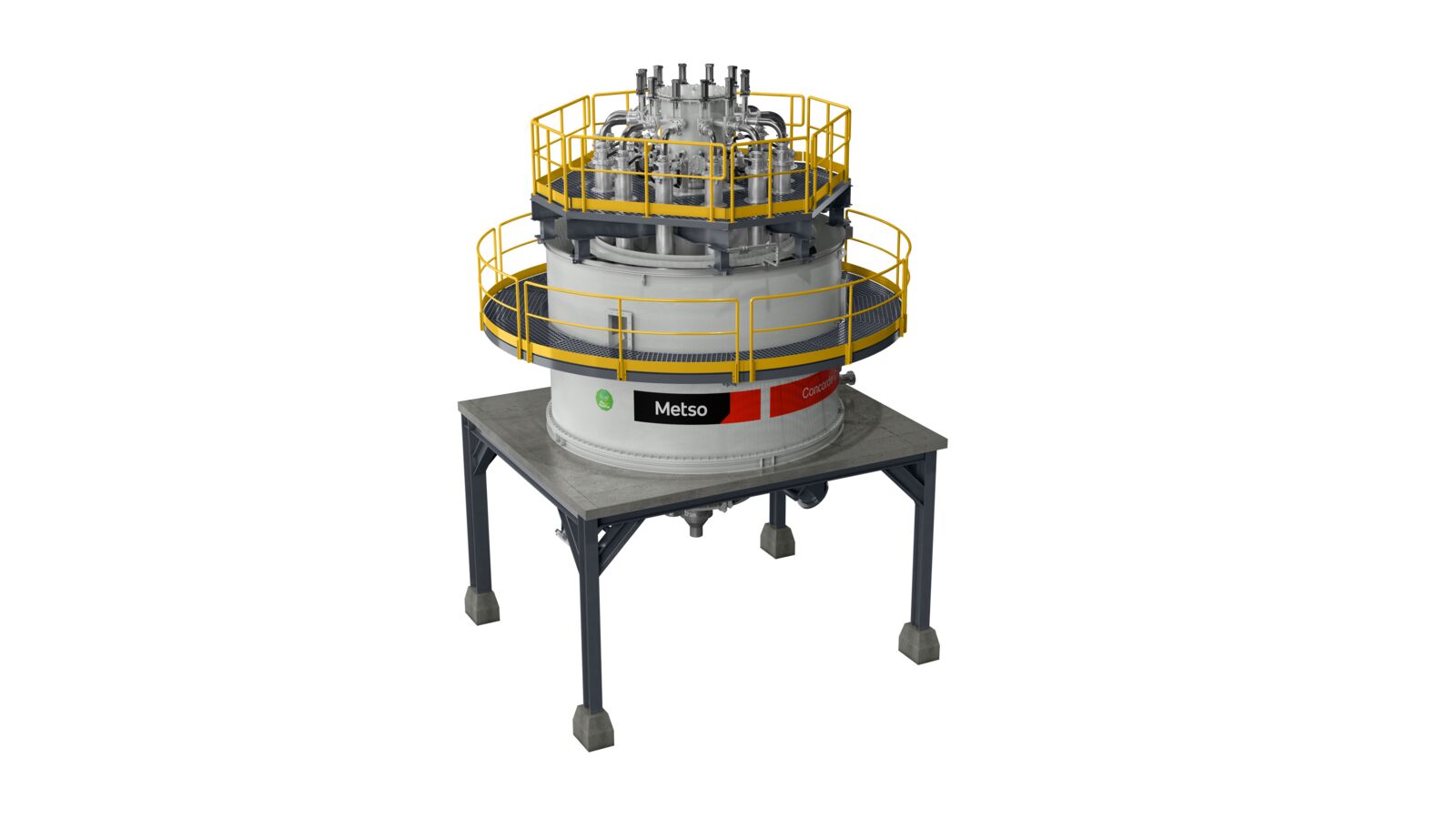

Advanced flotation technologies: Advanced flotation technologies such as high-intensity pneumatic flotation, offer improved selectivity, higher recovery rates, and greater adaptability to challenging ore types. These technologies provide a pathway to enhanced circuit performance.

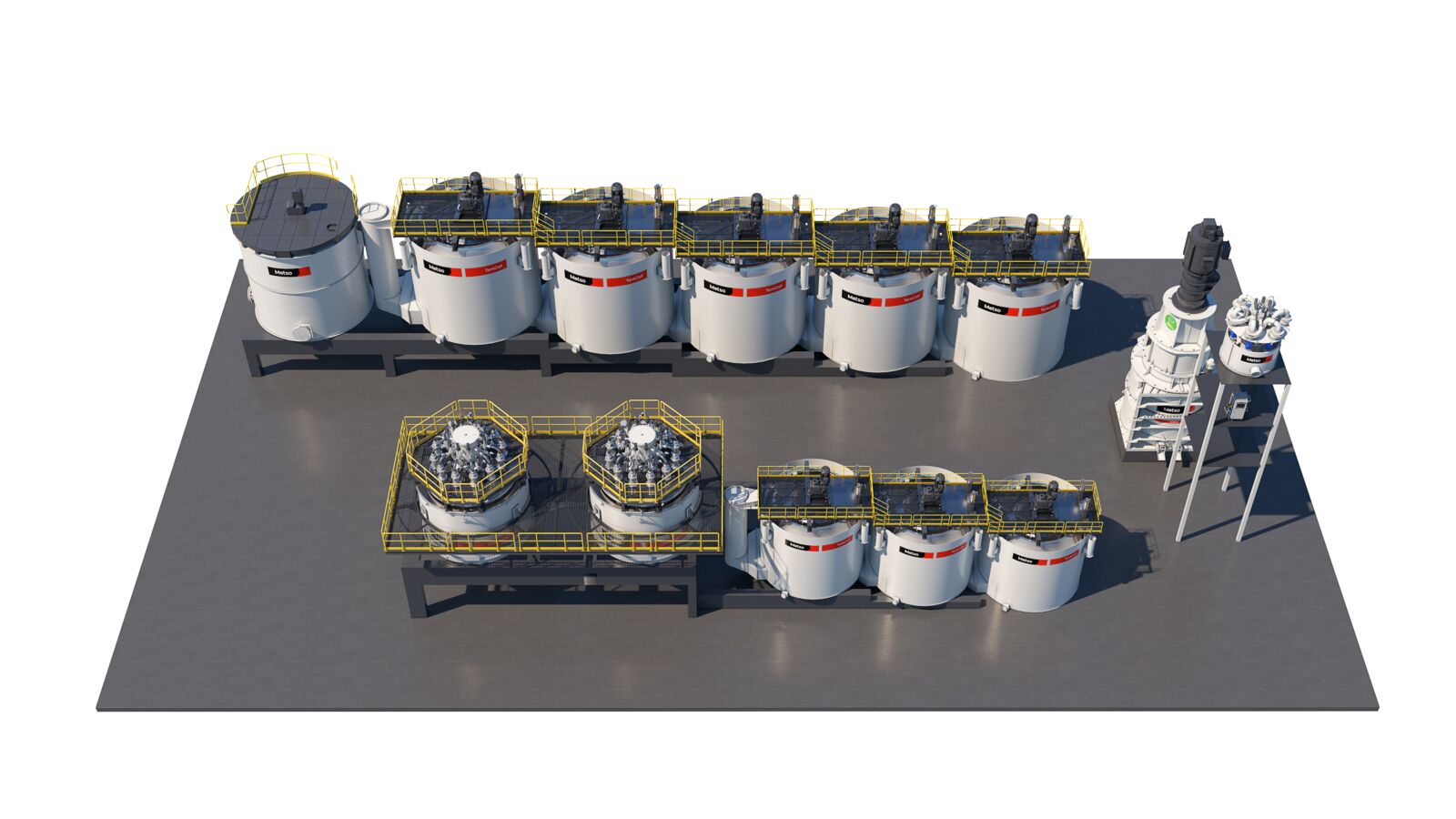

A comprehensive suite of technologies offers mining professionals a holistic approach to enhancing flotation circuit performance for inaccessible ores. By leveraging these solutions, operators can achieve improved recoveries, reduce environmental impact, and sustain operational efficiency in the face of challenging ore types.