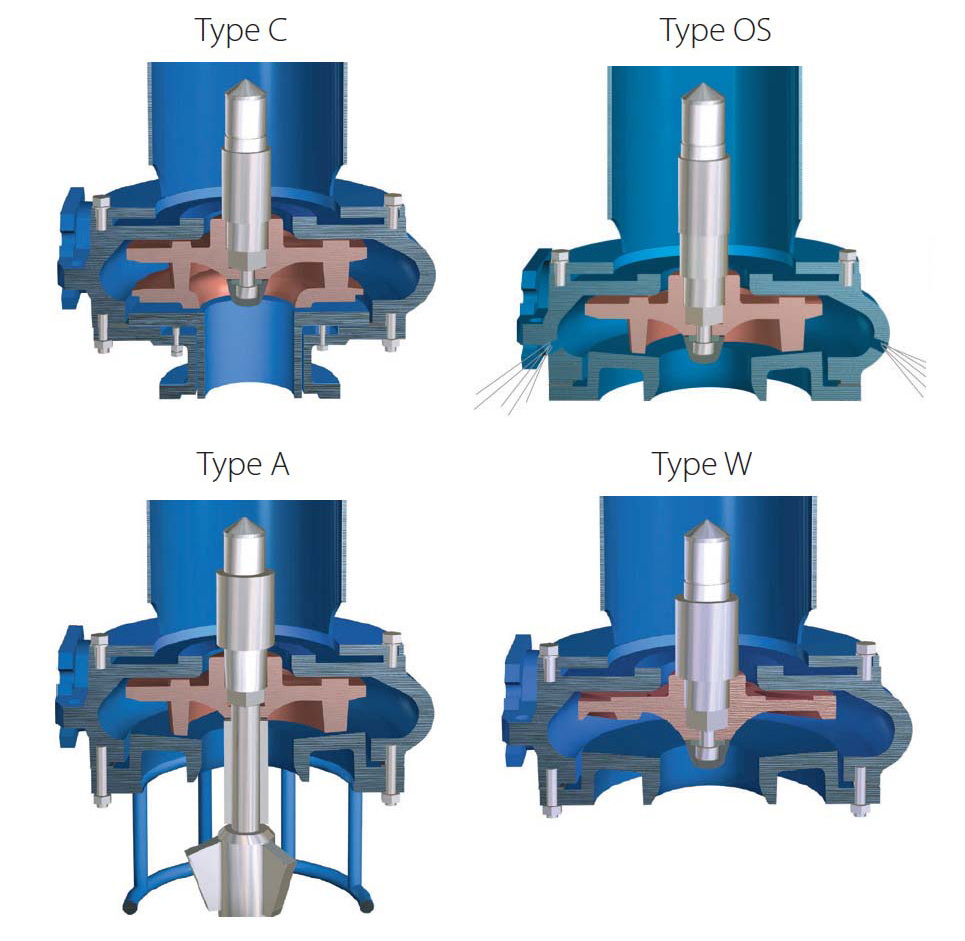

Type C - Closed impeller for high heads and efficiencies. Preferred in high wear application at high heads and where the sump is protected from oversized items.

Type OS - Semi open impeller and pump casing with spray holes. Provides better solids handling than the closed impeller design and is less sensitive to air blocking on intermittent operations. The spray holes direct some of the slurry towards the sump bottom, thereby agitating settled solids.

Type A - Semi open impeller, robust extended shaft with a slurry agitator. Used where solids are large and settling fast such as grinding and crusher area sump pumps.

Type W - Vortex induced flow impeller for pumping of long, fibrous, or coarse solids without the concern of blockages of impeller vanes. Originally developed for mill scale pumping in steel mills, where steel scrap sometimes is present but suitable for a range of applications.

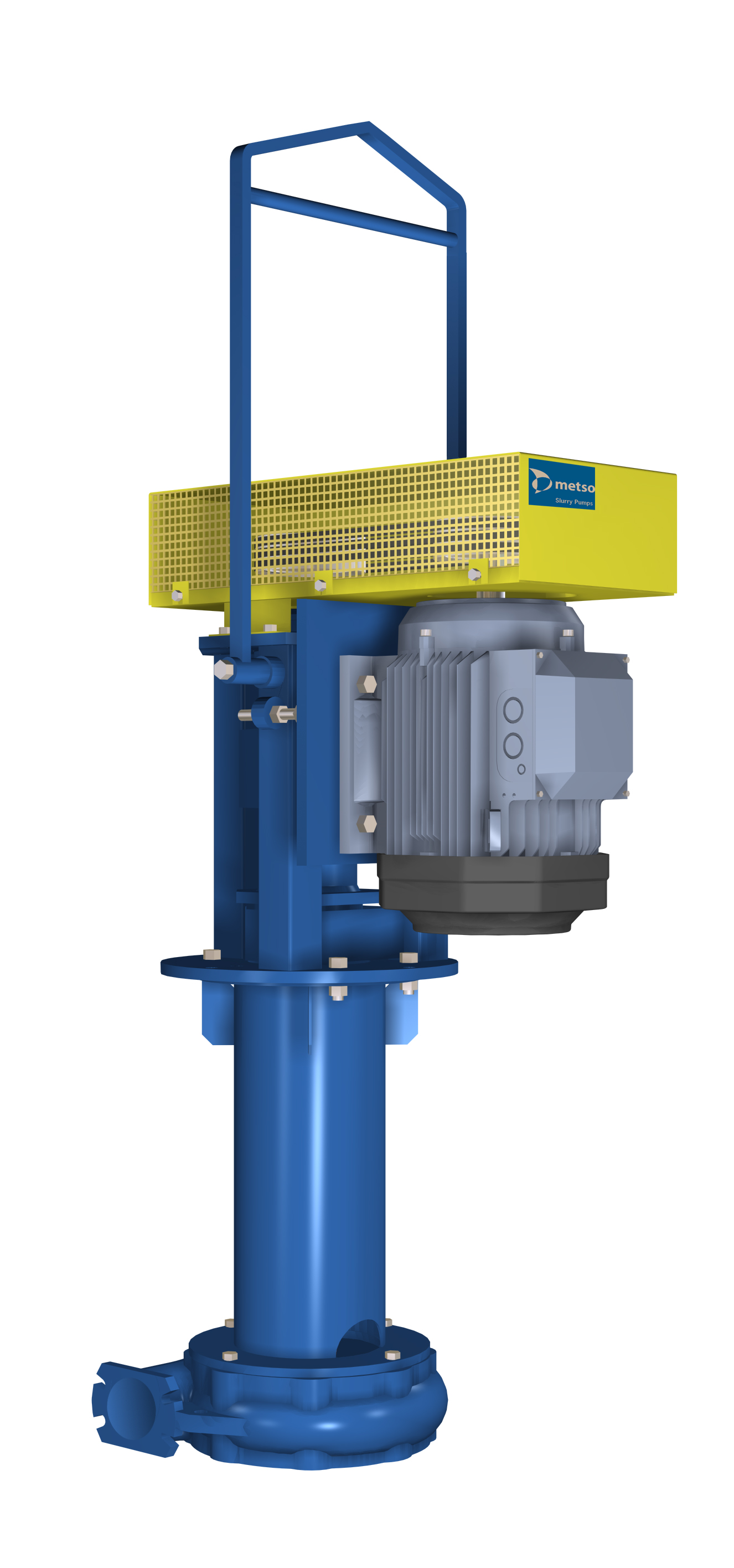

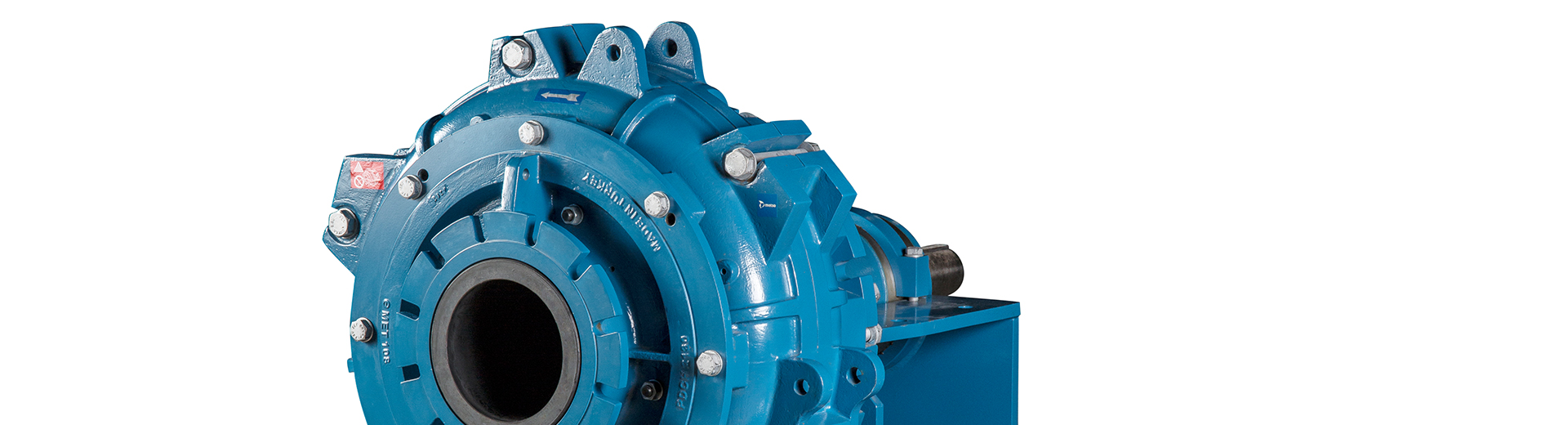

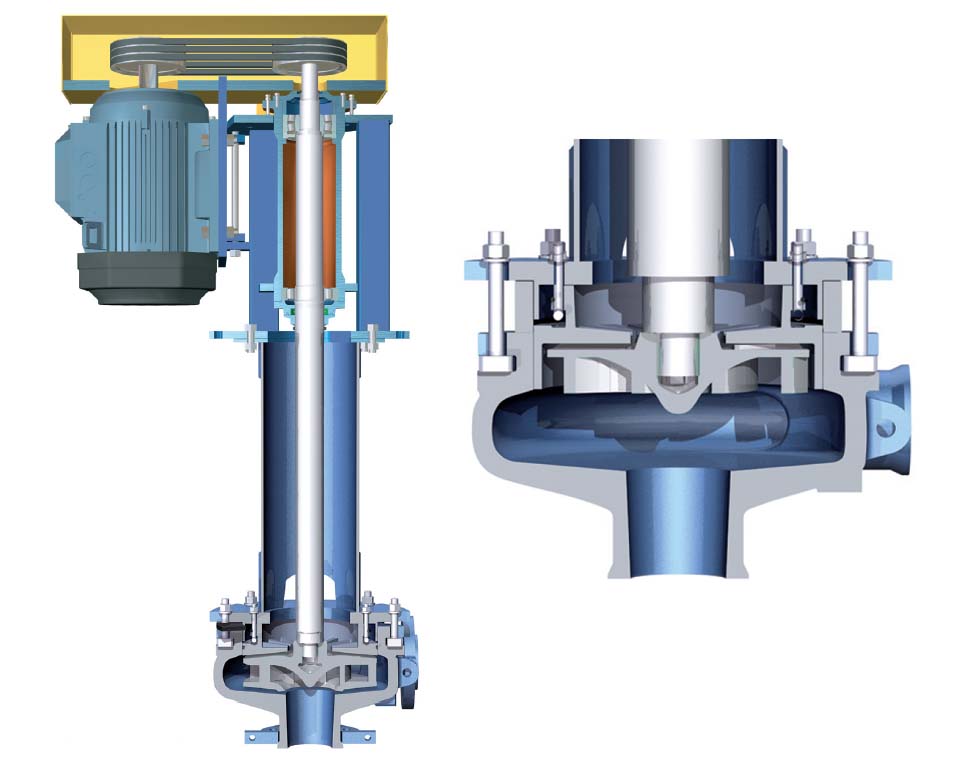

Extended application coverage with Orion Series

The combination of the VS pump and the Orion series horizontal wet ends opens up a wider range of applications and advantages.