Rising energy costs and declining ore grades are setting new challenges for the mining industry. As a result, there is demand for more energy-efficient circuits, with reduced number of operating machines. High Pressure Grinding Rolls utilize advanced technology to offer more energy-efficient grinding with increased throughput capacity and minimal maintenance activities. For many mines, the HPGR is a popular grinding solution to achieve cost savings and improved availability. Like any great solution, the HPGR does face some challenges in the field, particularly in the case of skewing.

Many HPGR operators will admit that they struggle with feed variance and segregation. Typically, these issues have pushed HPGR manufacturers to implement skewing control systems to regulate skewing within a tight tolerance. So, what is the truth? Our assessment – every HPGRs skews, but machine designs that promote skewing do not improve the operation of the HPGR. Here are the facts about three common myths around uneven pressure distribution across the width of the rolls and skewing. Before shining light on the myths around skewing, let us define the causes for uneven pressure distribution as these are leading the way towards understanding skewing and the limitations around this operating condition.

Defining the Edge effect and Feed size segregation

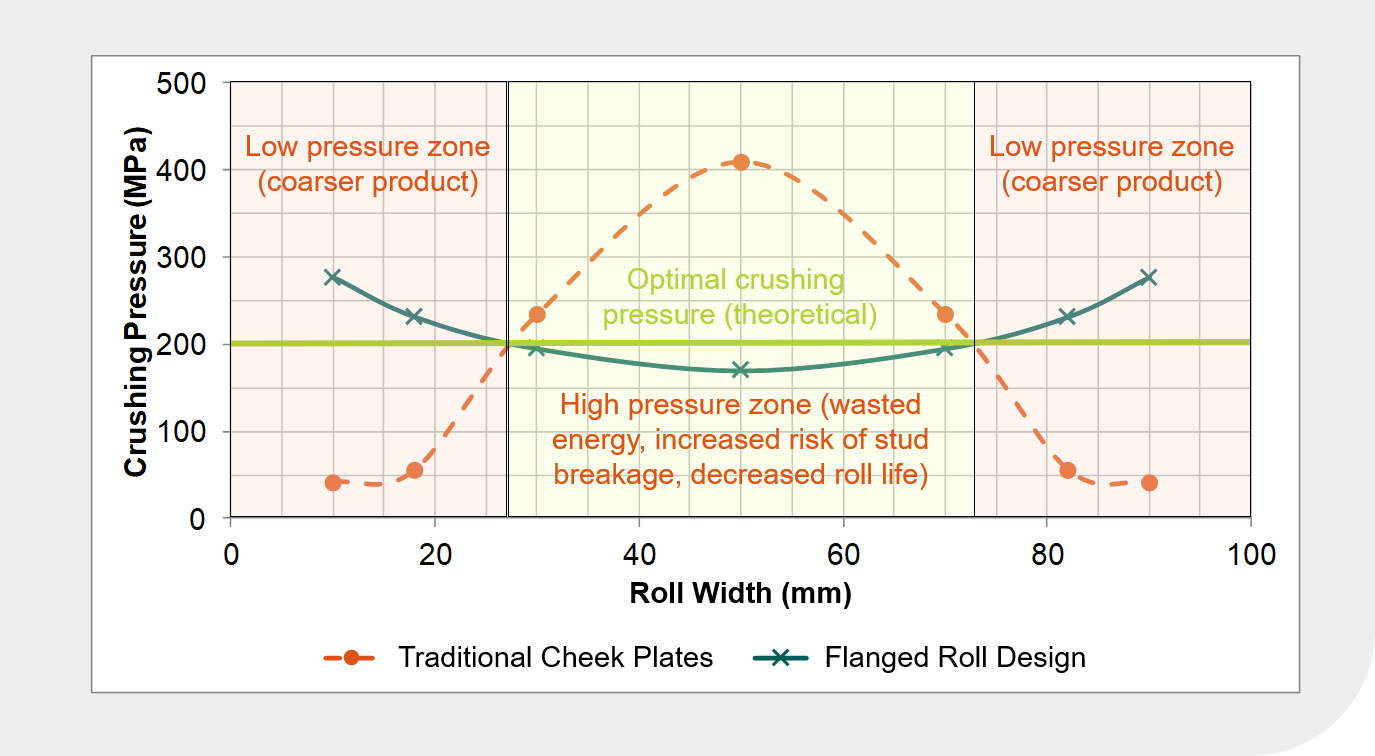

To operate HPGRs most efficiently, it is desired to have an even pressure profile across the width of the roll. Generally, the two main causes of uneven pressure distribution are the edge effect and feed size segregation. Looking at these two conditions, edge effect is a consequence of an HPGR design with static cheek plates, while feed size segregation is causing the HPGR to skew.

Edge effect

In traditional, non-flanged HPGRs, the pressure across the rolls is uneven, caused by a phenomenon called “edge effect”. This happens because ore bypasses the comminution process on both sides of the rolls. Static cheek plates are used to keep the material in between the rolls when it is being crushed and therefore to minimize the edge effect. However, the ore flow through the compression zone also has a directional component pressing against the static cheek plates, creating friction, slowing down the ore, causing a gradient within the mass flow. The gap between the cheek plates and the rolls increase, allowing ore to bypass, causing the pressure drop. This means that the smaller the distance between the rolls and the cheek plates, the better is the reduction of the edge effect. It also means that skewing can only be tolerated within a small range to avoid contact between the rolls and cheek plates. Some cheek plates are designed with springs to minimize the gap and to allow the roll to press the cheek plate sideways when skewing. This, however, causes significant wear on the roll and cheek plate which reduces the life of both components and subsequentially increases the edge effect.