Located in Salamanga, 90 km from Maputo, Mozambique, JRC is a contractor outsourced by a Brazilian private equity Intercement company, Cimentos de Moçambique, one of the biggest cement producers, with operations in more than eight countries in South America, Africa and Europe.

The Salamanga Quarry operation, which went into production in 1955, supplies all the limestone for Cimentos de Moçambique. The old primary crushing stage, located in the factory in Matola, had several major problems that were causing interruptions in uptime.

They also faced another challenge. The operating model was designed to transport 0/600mm rocks by train from the quarry to the cement plant. This resulted in high operating and transport costs, as well as high potential for safety risks.

“Loading the 600mm into the train caused a lot of unused space between the rocks; this not only prevented JRC from loading the tons to the maximum capacity, it also increased the safety risk due to the size of the rocks,” says Paulo Seiça Leitao, Metso Sales Manager.

When Metso was called in 2012 to consult on the equipment, they also recommended a new model for operations: do the crushing first in the quarry and then transport the smaller sized rocks to the cement plant.

From planning to action

Once the signature was in place, Metso pulled out all stops to get the project going. It took only four months for the equipment to arrive from Portugal to Mozambique. Plant assembly began at the beginning of January 2015, with full commissioning completed in record time of just over two months. Start-up took place on March 9, 2015.

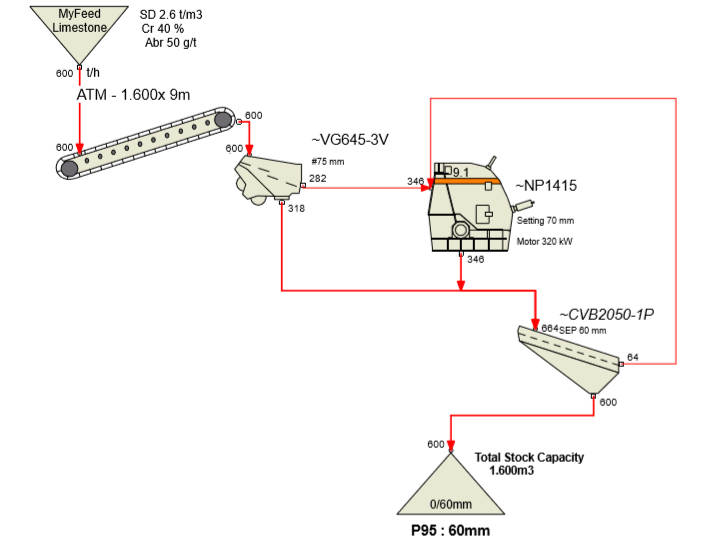

Metso installed a new crushing plant with its state-of-the-art equipment, including an apron feeder, a scalping screen VG645–3V™, an Impact crusher Nordberg® NP1415™ and a screen Compact CVB 2050–1P™.

Customer feedback has been highly positive, and with Metso’s support they continue to achieve their production targets with improved reliability and reduced commercial risks.

“The new crushing plant with Metso equipment has enabled us to increase our production output and reduce our operating costs. This can be attributed to increased reliability of the operation and automation, which now has a constant feed. In addition to this, we have also seen significant improvements in the plant’s environmental impacts,” says Marisa Conceição, JRC General Manager.