Commissioning and start up completed ahead of schedule

Metso appointed Roltech Engineering Ltd as their installation partner to make the necessary changes to the existing support structure and chute work required to complete a successful installation of the new crusher into the existing primary station. Roltech took on both principal designer and principal contractor roles under the CDM regulations and had a full-time site manager supervising the overall installation, as well as Metso engineers building up the crusher from the new support level.

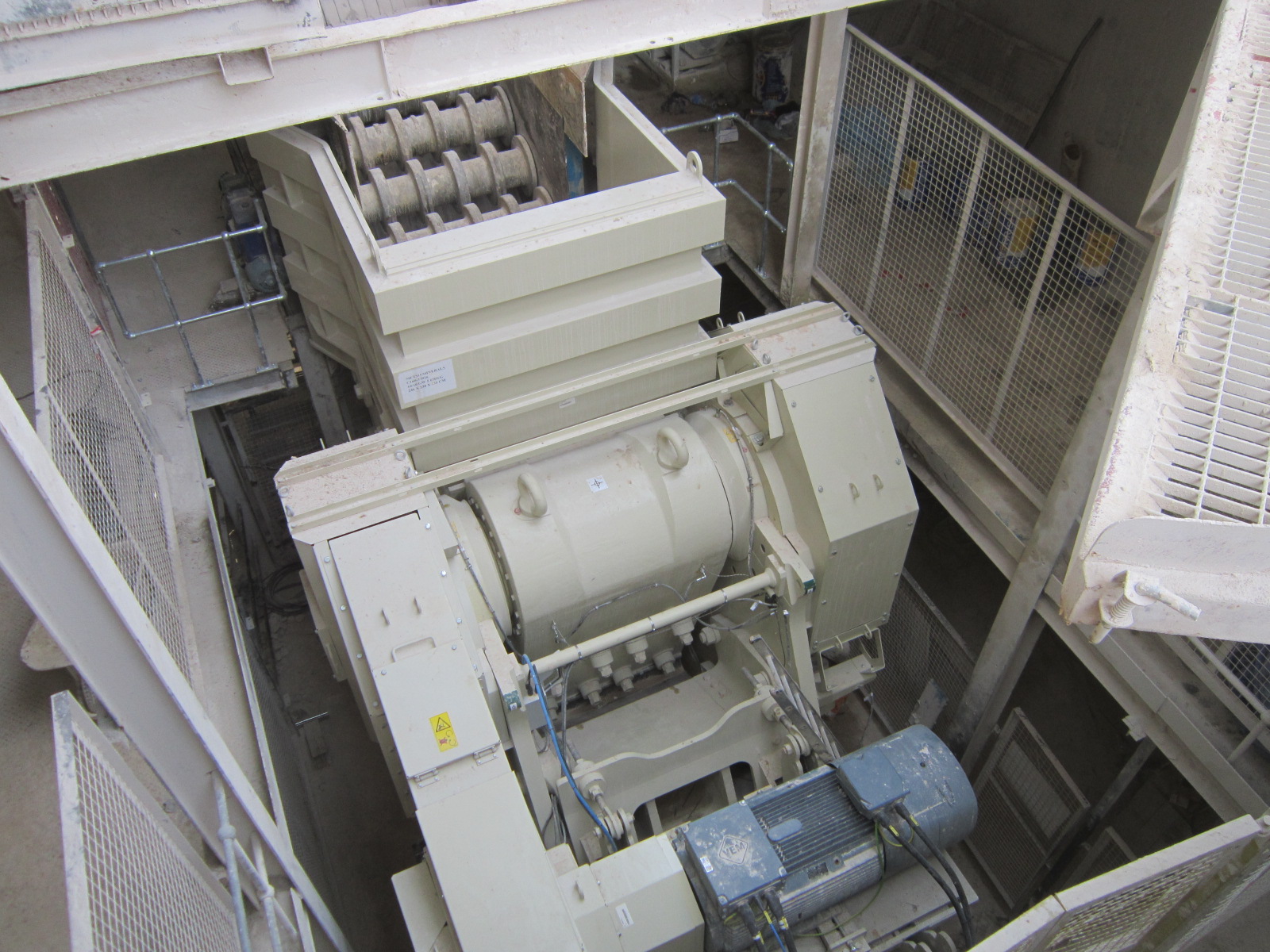

The new crusher had to be installed into the existing space, respecting the feed and conveyor system; to gain access, the roof and existing lifting beam had to be removed. The scope of installation also included a new magna start for the slip ring motor and electrical control panel. During the planning stage, which included all the stakeholders, it was determined that the best solution was to build up the crusher “in situ”. This overcame the challenge of crane access for the size of lifts involved with sufficient reach available for the best position near the primary building.

With the effort made during the planning stage and with everybody’s co-operation, the installation proved successful – and commissioning and start up were completed three days before the deadline.

Comprehensive results achieved

According to Andy Meadows, Group Engineering Manager from Longcliffe Quarries, the results are comprehensive:

-

Improved throughput

-

Impressive ability to crush marginal stones the size of the crusher mouth

-

Reduction in downtime and in use of the hydraulic breaker

-

Reduced downtime adjusting the crusher setting by using the hydraulic setting equipment

-

Improved maintenance with the auto lubrication system, the compact design of the machine and easy access to parts