Modern, automated plant that is easy to adjust

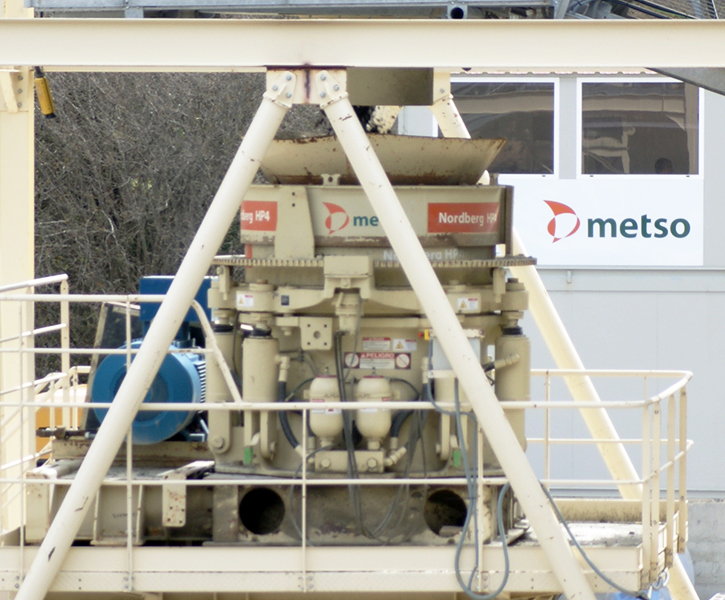

The new Ofitas de Santutis plant, designed by Metso Spain, combines new Metso equipment with the company's existing machine fleet.

"The setup is a fully automated plant, but the secondary and tertiary crushing stages can be flexibly adjusted, depending on the need, always giving end products with the same granular sizes," says Eduardo Diaz, Metso's Director of Engineering and Service in Spain.

"The customer is especially satisfied with the power solution. The plant is fed by two different generators, each feeding one section of the plant; this way, the whole plant doesn't get stopped because of a failure," concludes Diaz.

A long project to execute

"The quarry project has been long and laborious. We applied for the exploitation permits already 15 years ago. At first, only mobile equipment could be used. After 13 years, we were authorized to build a complete, stationary crushing and screening plant," says Iñigo Ajuria, Managing Director of Santutis de Ofitas.

The quarry has known ophite rock material reserves of more than 10 million tons with a Los Angeles value of between 9 and 11; this makes it top-quality material for the production of ballast for the Spanish high-speed trains.