H+H produces Aircrete, a lightweight masonry material that combines the strength, durability, and thermal efficiency of concrete with the convenience of a lighter material that is easy to cut and work with on-site. The materials used in the manufacture of H+H Aircrete are: sand, pulverized fuel ash (PFA), cement, lime, and water.

These are combined into a slurry with a small amount of aluminum powder added to the mix. This initiates a chemical reaction, generating minute bubbles that form the characteristic aircrete structure and appearance. When the mixture has partially set, the resultant “cakes” are wire-cut into blocks or panels and transferred into autoclaves for high-pressure curing.

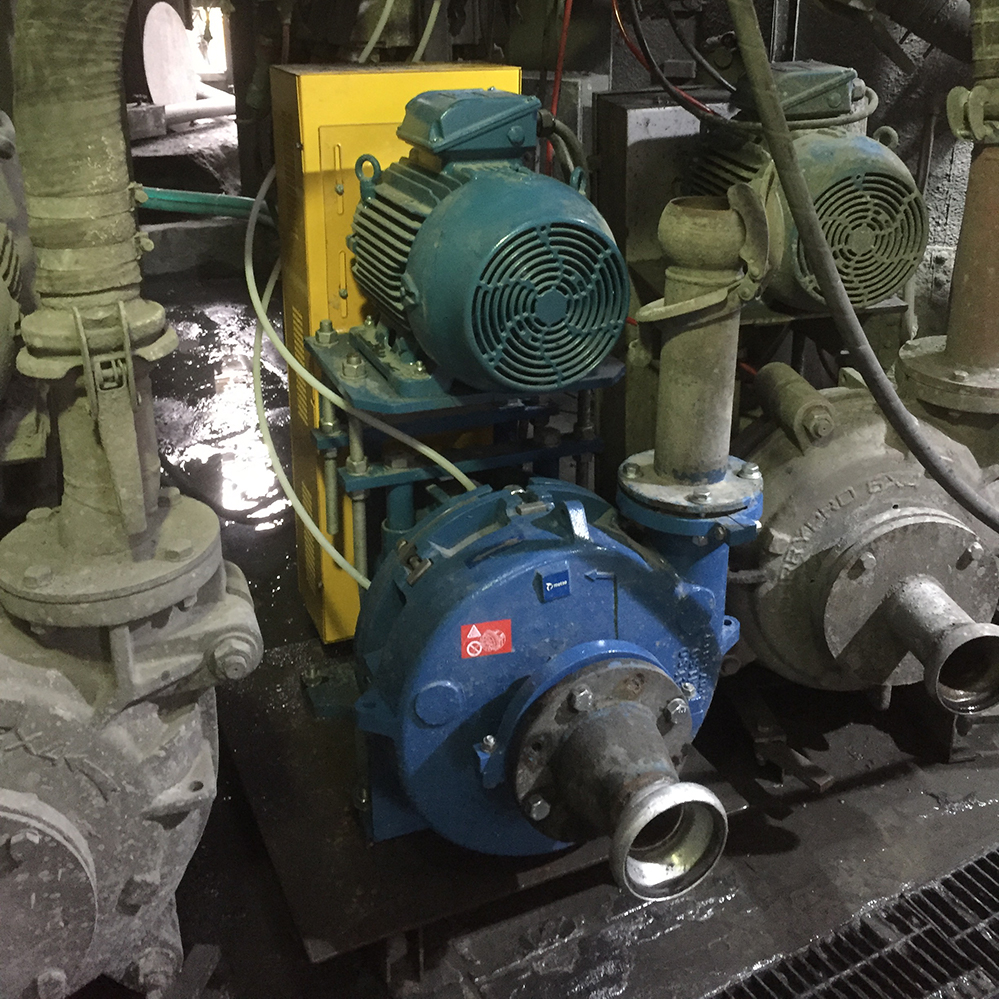

Pumps are used in the process at various locations including what is known as ”batch feed”, the most aggressive area of the process. That is where the block-making machines are fed with a thick slurry containing fly ash, sand, water, quicklime or lime sludge, cement, aluminum powder, and gypsum, with exact proportions dependent on client specifications. The slurry density was fairly consistent at approximately 1.6 SG.

Challenge

- Insufficient wear life of pumps parts

- Blockages

- Low production rates

Solution

- Two Metso Outotec Orion HM150 pumps

Benefit

- Extended wear life of parts

- Higher availability

Insufficient wear life with their previous pumps

Unsatisfied with their existing supplier’s pumps, H+H contacted Metso Outotec in hope we could find a solution to three main issues:

- Insufficient life from their existing 3rd party pumps, as the pulverized fuel ash (PFA) used to feed the process got coarser overtime. Originally, it had been possible to use rubber pumps because of the finer nature of the PFA. However, as the feed became coarser over time, this accelerated damage to the wear.

- Blockages were occurring with standard closed impellers that led to suboptimal production rates

- Spares requirement of the customer was not being met

“By discussing with the operational process staff, we were able to identify numerous operational issues that were occurring,” says Steve Sedgewick – Senior Manager, Pumps Business Line at Metso Outotec. “With our expertise, we were able to resolve these issues for the customer in our product offer.”

The Metso Outotec solution

The customer’s design criteria for the process was to use existing motor sizes whilst matching the flow and head of the current installations. Additionally, they hoped for equipment that would provide a good wear life without incurring process incidents such as blockages.

Metso Outotec first provided an Orion HM150 pump on trial at H+H’s Pollington site in Yorkshire.

“With this trial, we were able to prove our product versus existing pumps and pumps from competitors”, says Greg Dixon - Senior Pump Sales Manager, Europe at Metso Outotec.

The Metso Outotec Orion Heavy Duty pumps are designed for the toughest pumping applications. The Heavy-duty Metal variant (HM) features a class-leading design, with extra thick sections at known points of wear and a high aspect ratio impeller. This results in a long wear life as well as excellent performance.

“Wear life and performance are further optimized through the modular pump design which provides a choice of impeller design and gland seal options,” adds Greg. ”For this particular application, we offered a solution to their issues that their existing supplier was not able to provide an equivalent for.”