Building an aggregate crushing plant that responds to constant market changes

The quarry project started in the early 2000s by requesting all the necessary permits. After many years in the planning and administration stages, the plant was commissioned in 2016. The Ofitas de Santutis operation is located in the municipality of Peñacerrada, in Álava, northern Spain, near Bilbao.

Mr. Iñigo Ajuria, Owner & General Manager of OSF Group, and Mr. Carlos Fernandez, Engineer Manager of the Ofitas de San Felices quarry, had plenty of time to think about the design of their new plant. During that period, the economy was going up and down, so they wanted a plant that could easily adjust to the needed production capacity and the demands of the market.

The Ofitas quarry, an ophite operation, produces high-quality sand, gravel and ballast. The ballast is mainly delivered to the rail infrastructure works in central and northern Spain; the ballast has a Los Angeles index between 9 and 11, making it suitable for use on the high-speed train network. The sand and gravel go to local works in the surrounding area.

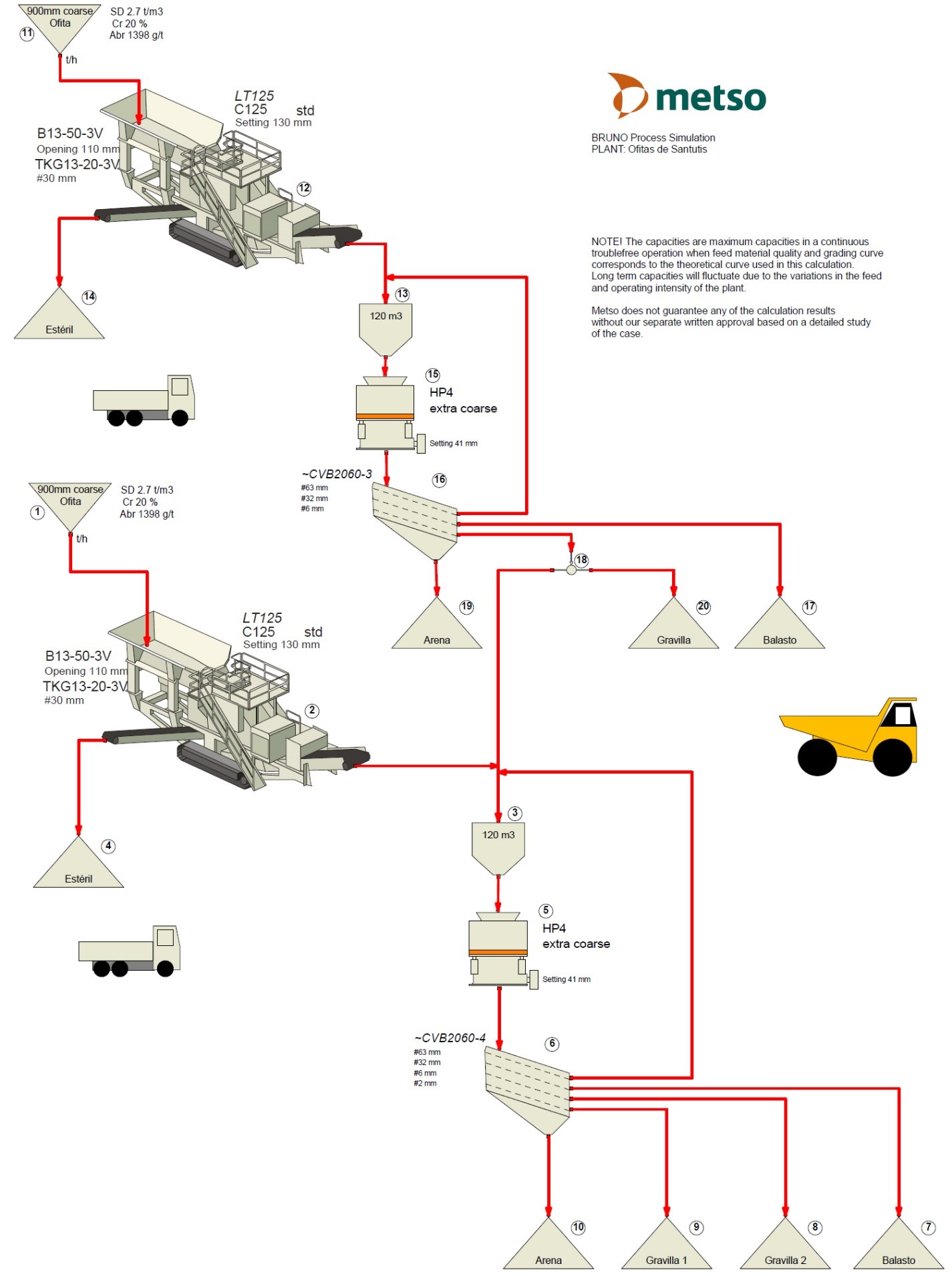

The plant was designed so that it allows working with a primary, secondary and tertiary crusher, or with two secondary crushers for maximum ballast production, or with two tertiary crushers for gravel production.

“We had a long track record of working with Metso and had built personal relationships with them over the course of many years, so the level of trust in them was high. We had no doubt that Metso would deliver what we wanted,” says Iñigo. “We’re extremely happy with the solution they provided. The whole plant brings us the desired results in response to the changes demanded by the market.”

A crushing plant with a highly innovative, multifunctional and flexible configuration

The plant configuration consists of Metso’s Lokotrack® LT125™ primary mobile jaw crusher followed by two Nordberg® HP4 cone crushers working as secondary and tertiary crushers. In this configuration, the plant’s capacity is 400 tonnes per hour. This being the most logical setup, the cone crushers can also work simultaneously as secondary or tertiary units. In doing so, the plant’s capacity is simply doubled to 800 tonnes per hour.