Santa Isabel Quarry has been in operation since 1959 and is part of Votorantim Cimentos, one of the largest business groups in Brazil. Located in Mogi das Cruzes, in Greater São Paulo, the quarry serves customers in the metropolitan region of the largest Brazilian city and provides aggregates for civil construction, major works and cement block producers. However, the company’s positive story was jeopardized in 2018.

The reason is simple: Santa Isabel faced two major challenges. In addition to the retraction in civil construction, the plant was having problems due to aggregate contamination and an above-average presence of fines. Both had a negative impact on buyers’ perception of the final quality and on Santa Isabel’s sales. On the sand and gravel market, buyers prefer materials with controlled levels of contaminants and dust. In other words, “cleaner” aggregates.

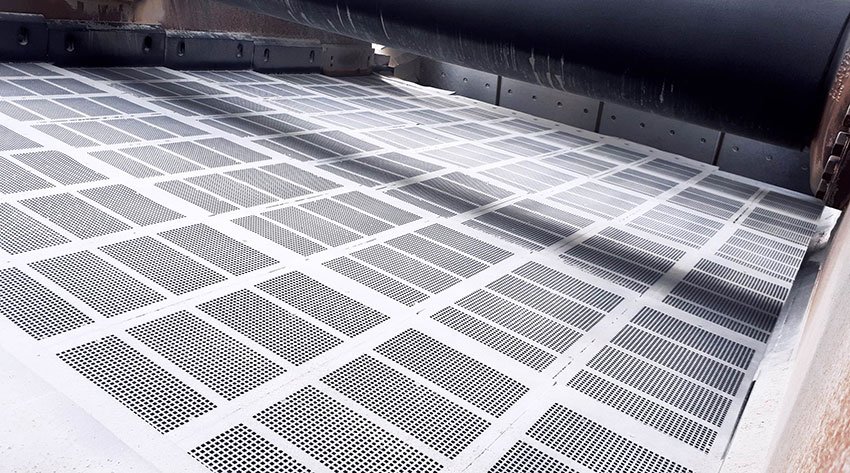

With the arrival of the new regional manager, Carlos José Barbosa Silva, the quarry began to implement operational changes, including training employees and addressing the main technical problem – the improvements needed in the aggregate screening process. Specialists from Metso Outotec were invited to assess the operational efficiency of the screens. “We had already faced a similar problem at the Araçariguama quarry and achieved good results with the solution presented. The screens were retrofitted and the wire media were replaced with Metso Outotec’s high-resilience rubber screening media,” comments Carlos.