Making world-class records

Just south of Gällivare in the north-central part of Sweden lies Boliden Aitik, the country’s largest open pit copper mine with an impressive depth of 450 meters. Operations include mining for copper, gold and silver around the clock.

Originally established in 1968, the mine belongs to the Boliden Group. Today, The Boliden Aitik mine is one of the most efficient in the world and is the largest employer in the Gällivare municipality with 650 people. The mine is also unique in that nearly as many women operate the huge, powerful mining machines as men do, making Boliden Aitik the most gender-neutral mine in the world.

Custom solution wanted

As a key priority to develop profitability, Boliden Aitik decided to raise efficiency and productivity by setting a new production goal of 45 million tonnes – a production increase of 25%. This huge challenge meant that every single part of the plant had to be optimized for peak efficiency.

The mine began by identifying its bottlenecks. One initial finding showed that if they increased the concentrator volumes, they would run into capacity limitations with the existing tailings from the plant. This would prevent them from reaching their production goals.

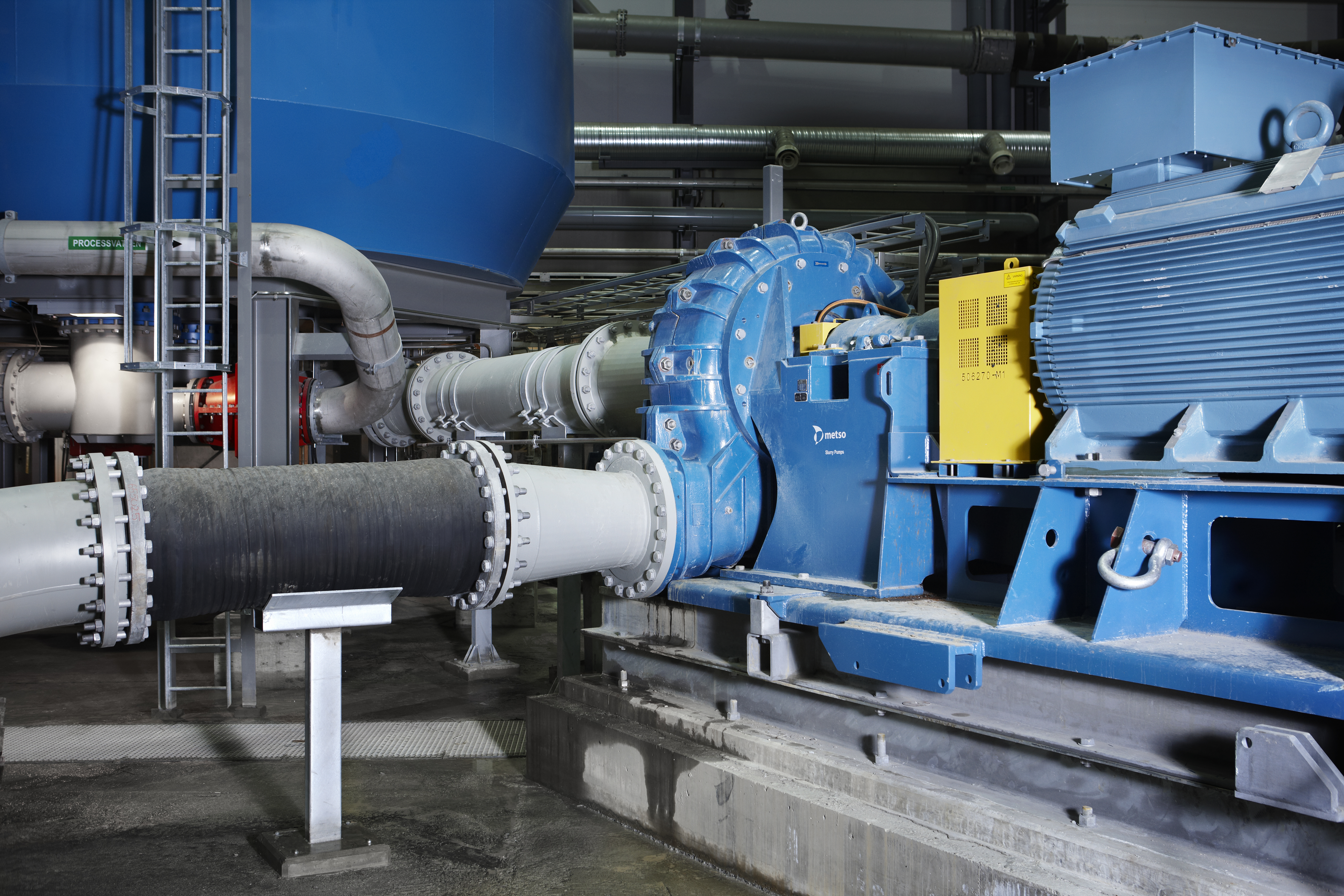

For Boliden Aitik, it was clear that they needed a custom-made solution that would fit with their existing tailing system. The mine also wanted a tailing system that was specifically designed for heavy-duty applications, and one that would be easy to install with low maintenance.

Another critical factor was that Boliden Aitik needed to find a supplier who could deliver within a short time frame. They turned to Metso for consultation.