It is important to note, that when crushing ore there is an optimum pressure for a given feed. Below this optimum pressure, less breakage will occur, while above the optimum pressure the energy efficiency will decrease. Therefore, it is important to have consistent pressure across the full width of the roll, so that an optimal pressure can be applied to the full bed of material. In the case of the traditional cheek plate design, the total pressure to the system is commonly raised to increase the amount of breakage at the edges of the roll. However, this results in higher pressure being applied to the center of the roll, leading to wasted energy and added wear in the center area of the roll. In addition, the higher localized pressure associated with the cheek plate design needs to be considered when selecting the stud hardness and composition in order to prevent stud breakage. The results of this lab test gave the engineering team the confidence to proceed with the flanged HPGR design on the pilot scale unit.

Pilot plant confirms lab findings

Prior to installation of the HRC™3000, a pilot scale plant was installed at the Morenci Concentrator to use as a proving ground for the HRC™ HPGR.

The pilot plant included an HRC™ HPGR with 750 mm x 400 mm rolls, a primary wet screen, and a secondary wet screen. The HRC™ HPGR was fed by the primary and secondary screen oversize. The primary and secondary screen undersize was then transferred to the downstream process. The capacity of the plant varied depending on the circuit configuration, but in most conditions it could process approximately 50 - 70 tph. The F80 to the HRC™ HPGR varied significantly and ranged from 11 mm to +16 mm.

A series of twelve process surveys were performed at the pilot plant to better understand how the flanged roll design affects the performance of the HRC™ HPGR circuit. These surveys, identified as the edge effect testing series, showed that in all conditions and pressures, the flanges clearly provided more breakage across the width of the roll and increased the throughput of the HRC™ HPGR relative to a traditional cheek plate HPGR design. On average, the flanges were shown to reduce circuit specific energy by an average of 13.5% and to lower circulating load by approximately 24%, while increasing the specific throughput of the machine by 19%.

In addition to test the design, the pilot plant testing aimed to provide a better understanding of the performance of the circuit, and to give the plant personnel experience operating and maintaining an HPGR circuit.

From problem-solving to successful installation

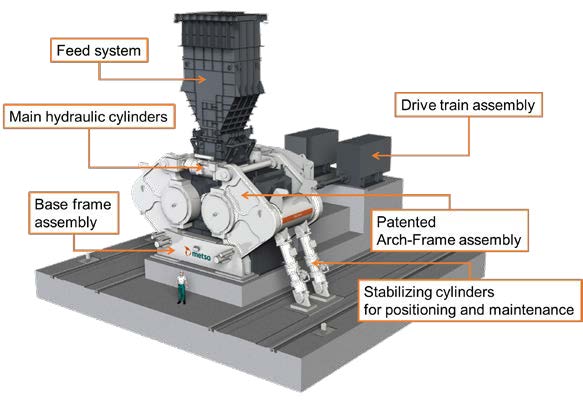

The HRC™3000’s capacity is approximately double the capacity of the largest preceding HPGR in operation. It was unknown what issues would arise when scaling up to a machine that is over 50 times larger than the design prototype. In order to ensure the proper design of the Arch-frame, a series of structural analyses were performed prior to the final design of the HRC™3000.

While the new machine concept eliminated some traditional HPGR design concerns, it did introduce new design considerations. For example, the interface between the pivoting Arch-frame/roll assembly and the stationary dust enclosure and feed chute needed to be carefully designed. An integrated tramp bypass system was developed in order to eliminate the requirement for additional infrastructure typical of HPGR installations.

Installation of the HRC™3000 at the Metcalf concentrator started in September of 2013. For the installation of the HRC™3000, Metso provided the installation crew and field service supervision. This allowed for very close communication between the engineering team and the installation team.

The size of the large components needed to be considered for the installation phase of the project. Transporting the shaft from the laydown yard to the Metcalf building required coordination with site personnel to arrange for the use of the truck needed to move the 97 ton component, as well as the use of the overhead crane needed to lift it.

A machine as large as the HRC™3000 requires a significant infrastructure to support it. In multiple cases, the actual dimensions between the structural steel and the machine were different than originally designed. In some cases, the remedy was not a simple solution. For example, when installing the hydraulic cylinders, the amount of room between the steelwork was not enough to install the cylinders as originally planned. A different lifting fixture had to be designed to move the cylinders into place. Moreover, maintenance had to be carefully considered in order to safely access and handle the large components. A 20 ton gantry crane was installed inside the steelwork tower to handle the hopper and feed guide plates. In addition, 0.5 ton robotic arms are used to handle the maintenance for the edge blocks and flange segments.

Promising results

The HRC™3000 is to date the largest HPGR ever put into operation. At the time of writing, it has operated for over 11,000 hours. During that time, a total of 46,100,000 tons have been crushed by the HRC™3000 and the HPGR circuit has processed over 30,600,000 tons of ore.

The operational benefits of the flanged roll design, first tested on the pilot plant, were shown to exceed predictions on the HRC™3000. Table 1 shows a comparison of the predictions based on the pilot plant surveys versus the actual operating results at the HRC™3000. The higher-than-predicted machine throughput and increased particle breakage resulted in higher circuit capacity and it decreased circuit specific energy. In addition, the flanges have provided an even pressure distribution across the width of the rolls, which has allowed for installation of harder studs and ultimately has increased the life of the rolls.

Table 1 – Operating results

|

|

Predicted (based on flanged pilot plant tests)

|

Actual*

|

|

Operating gap (mm)

|

99

|

95 – 125

|

|

Specific throughput (t∙s/m3-hr)

|

276

|

310 – 360

|

|

Circulating load (%)

|

58 – 85

|

40 - 60

|

|

Specific energy (kW∙h/mt)

|

1.5

|

1.10 – 1.25

|

* Values based on typical operating pressure of 3.0 N/mm2

Additionally the HRC™3000 provides circuit flexibility compared to a traditional milling circuit. Both the speed and pressure can be changed online to meet the changing needs of the downstream circuit. The pressure can be increased, for example, if the plant is processing a harder ore. The HRC™3000 is capable of running at 30% nominal speed, which effectively reduces its capacity by the same amount. Under normal plant operations, the single HRC™ HPGR feeds two 7.3m (24 ft) ball mills. During times when one of the ball mills is offline, the plant can still operate at reduced capacity by turning down the HRC™ HPGR and feeding only one of the ball mills.