The successful installation by Outotec of one 53m diameter high rate thickener at TISCO Jianshan Iron Mine underlines the significant benefits of high rate thickening compared to conventional thickening. This one Outotec thickener has replaced two existing thickeners each of 53m diameter and achieved an increased tailings capacity in just one thickening stage. Since the installation, the resulting overflow liquor is of excellent quality, and easily reusable as process water. This installation by Outotec was the first of its kind in China, with more than 1000 installations globally.

Taiyuan Iron & Steel (Group) Co., Ltd. (TISCO) is a large iron and steel producer in China and an advanced stainless steel producer. As the largest subsidiary company of TISCO Group, the TISCO Mining Company sites include the Jianshan Iron Mine, Ekou Iron Mine, Yuanjiacun Iron Mine (under construction - 2009), Dongshan Limestone Mine and Daguanshan Dolomite Mine.

TISCO’s Jianshan mine lies in Loufan County, Shanxi province, China, 115km from the city of Taiyuan. Since founded in 1992, Jianshan has become the primary iron concentrate supplier for TISCO. The beneficiation process uses three stages of crushing, three stages of grinding, five stages of magnetic separation and anionic reverse flotation.

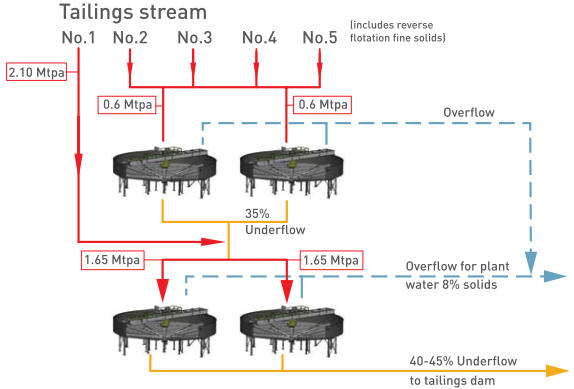

Previous primary thickening circuit

The old primary tailings thickening circuit at Jianshan consisted of a two-stage thickening process, requiring more time and energy to operate. Four tailings streams, including fine solids from reverse flotation (tailings stream No. 2-5), were split into two 53m diameter conventional thickeners, where they were thickened to an underflow density around 35%w/w solids. The underflow from both thickeners were combined with tailings stream No.1, a coarser solids stream from the magnetic separators, before being split into another two 53m diameter conventional thickeners. The final underflow at 40-45% solids was pumped to the tailings dam, with overflow from each thickener recycled to the plant.