Located in the Valparaíso region, Andina stands out for being Codelco's division with the highest copper mineral reserves in the country, combining open-pit and underground operations at more than 3,000 meters above sea level.

Copper production is a vital industry in Chile, with each piece of equipment involved requiring precise care and maintenance to avoid unplanned failures.

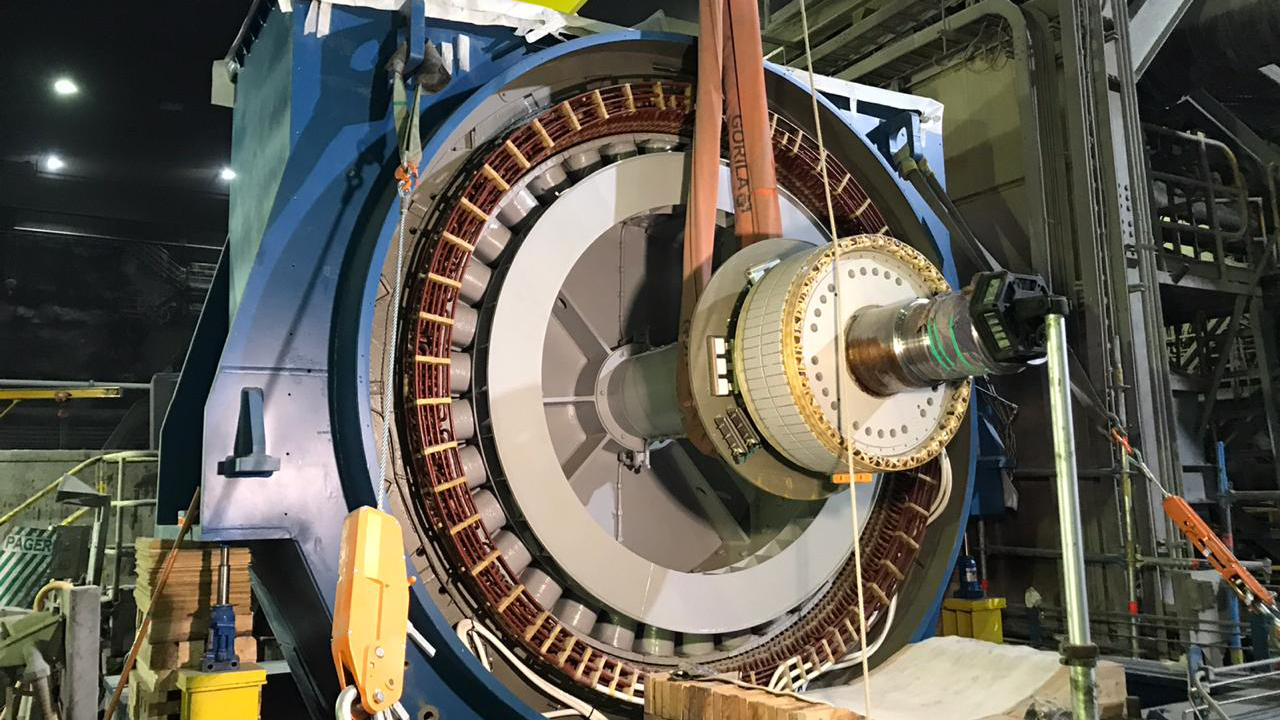

Due to the great technical knowledge and safety protocols of Metso Outotec in this type of work, Codelco Andina invited the company to participate in the change-out of two of its 7500 and 8500 HP SAG grinding ball mill motors in the interior of its underground operation. This was not a minor challenge considering the size of the components and the space constraints of the underground operation. It is for this reason that Metso Outotec decided to accept the challenge and unite its Field Services and A&CA work teams to carry out the task of mobilizing the 650 tons of major components.

The teams planned, designed and executed the project, which included the removal of the Westinghouse motor, assembly of the WEG motor bedplate, assembly of the WEG motor stator, threading of the WEG motor stator-rotor as well as the unthreading of the WH stator-rotor, over the course of 2 months.