Metso Outotec used its extensive know-how as a stockyard equipment supplier to extend the service life of the ore stacker/reclaimer dating from the 1970s that was in a critical structural condition. The service contract was delivered in September 2022 and is an example of a technological upgrade and service life extension project focused on reliability and availability. One of the highlights is the fact that it was performed on the equipment from another manufacturer.

The challenge started during the proposal phase, as it had an old design and no detailed engineering documents available. This led to great engineering efforts to collect reliable field data for the refurbishment project.

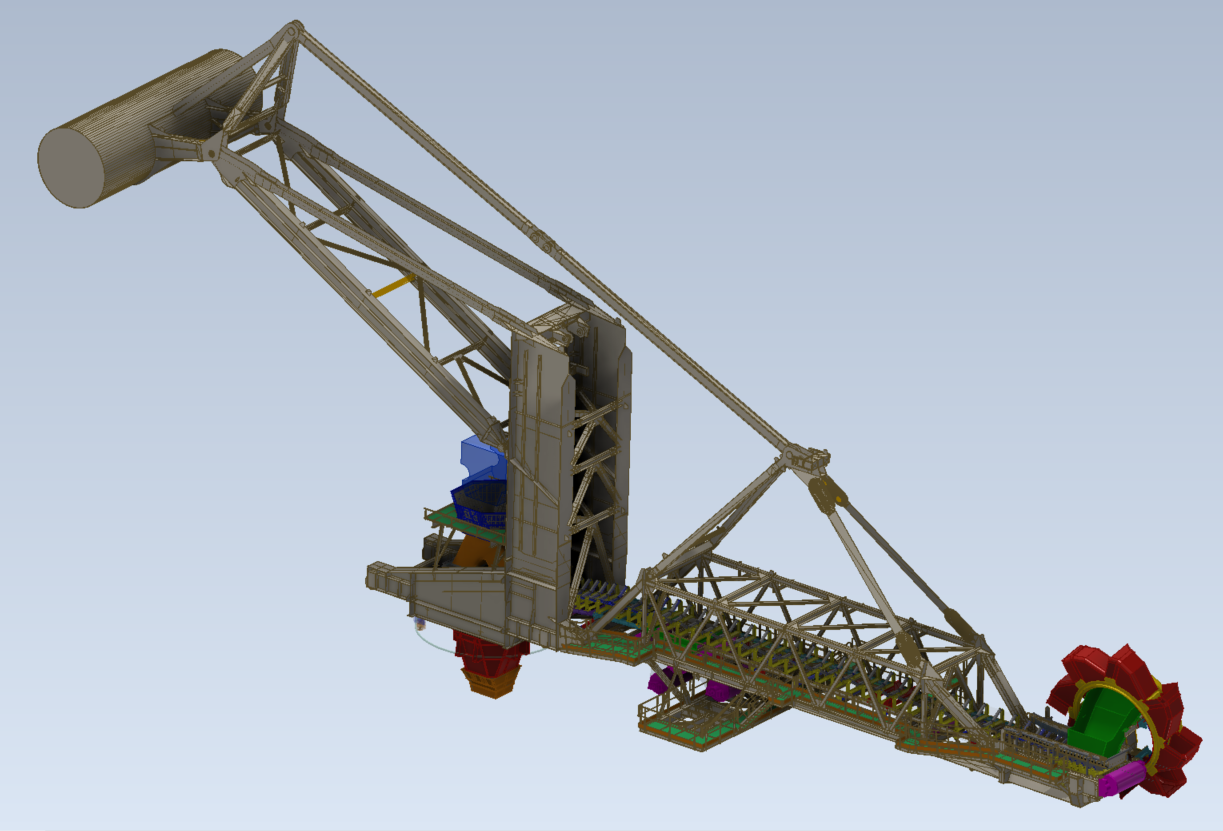

With all the engineered, manufactured and assembled parts weighing around 200 tons, the machine had to be 3D modeled using Metso Outotec's cutting-edge technologies. The field engineering services team started with the survey and identification of parts that could not be reused and therefore had to be fabricated by Metso Outotec. During the reverse engineering process, the parts dimensions were checked on-site individually. Later, Metso Outotec experts made a model that could be used to perform detailed engineering and perform the structural calculations that guaranteed the project delivery to the applicable standards and criteria.