Commissioning

Dry, wet and process commissioning were conducted following installation.

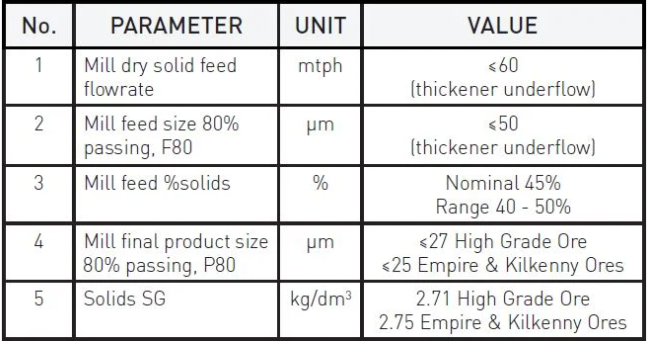

Poor grind was experienced during commissioning, which was put down to several factors: the media charge was not seasoned as it contained only 2.5mm media: the processed ore at the time contained higher clay content, resulting in higher viscosity slurry at 45% w/w solids density: and media packing in the milling chambers. Furthermore, media loss was observed to be exiting the mill with the product.

Initial operation

As with conventional grinding mills, stirred milling requires a seasoned charge for the first fill. In this case, there was no ceramic media present in the charge between the 2.5mm and 1mm size fraction. A seasoned charge reduces the voidage and maximizes the surface area of the charge, this being beneficial to fine grinding. Based on the signature plot monitoring, it was estimated that it took 2 to 4 weeks of operation to season the charge.

The amount of clay and ultrafine particles present in the feed greatly influences the viscosity. The thickener underflow viscosity is closely linked with the lime addition while treating clay-type ore. The HIGmill, while in constant power draw mode, was observed to be speeding up and slowing down depending on the lime addition pH CV.

Media packing was observed during the first inspection. The media packing is thought to accelerate the wear of the steel rotors which achieved a life of only 8 weeks for the first rotor set.

A small amount of media loss was observed to be exiting the mill with the product. This was thought to be due to the combination of the high flow rate through the mill and the resulting high mill speed required to draw the power, which creates a vortex. The variation of the media filling level was investigated. It was found that the SGE efficiency increases by ~2.4% with increasing mill filling level from 60 to 72% v/v. This is most likely due to the improving residence time distribution in the mill. It was also found that a reduction in flowrate greatly improved the SGE efficiency and allowed the mill to run at slower speeds at the same power draw.

Process power and control

Process control of the HIGmill was straightforward given the open circuit arrangement. The feed density is controlled by the pre-leach thickener, which has been configured to run on bed pressure control.

The HIGmill starting and stopping sequences are fully automatic, requiring no operator input. The HIGmill power can be set in various ways, Cracow opted for power control as the primary control method as it achieves the minimum grind size and maximizes gold recovery.