Located in Huangshi, China lies the world’s largest TSL smelter operated by Daye Non-Ferrous Metals Co., China’s oldest copper producer. The smelter has been operating for almost 10 years and has a design throughput of more than 1.5Mtpa of copper concentrates. The site is currently facing challenges to reduce their environment footprint whilst simultaneously increasing production and operational efficiency.

Environmental sustainability is at the forefront of industry conversation, and metals processing is no exception. With the continued push to improve energy efficiency, increase throughput and reduce CO2 emissions, increased use of oxygen in non-ferrous smelting presents a compelling pathway to achieving these goals.

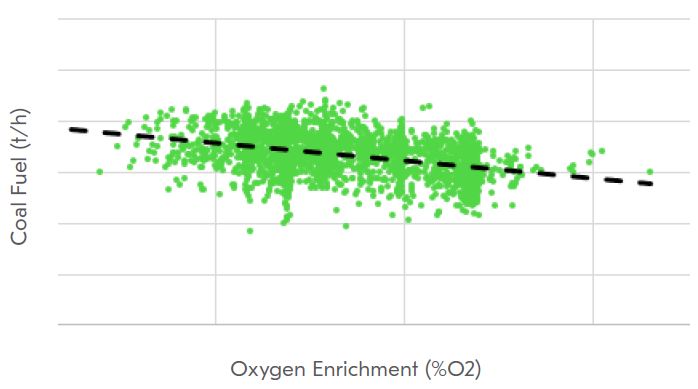

Through close collaboration during the engineering design and commissioning phases of the project, Metso Outotec was able to assist DAYE in improving performance of their Ausmelt TSL copper smelter by increasing oxygen enrichment of the process air up to 75%. Due to an innovative lance modification, this upgrade resulted in a variety of short-term and long-term benefits, including financial, operational, as well as environmental.