The partnership between Dundee Precious Metals and Metso has been a journey towards digital transformation, showcased in previous cases together such as Courier® 6G SL analyzer and the success story with Geminex™ metallurgical digital twin. Metso's integral role in this journey is evident at two Dundee Precious Metals sites, Ada Tepe and Chelopech, where substantial progress in performance has been made due to the implementation of Metso’s digital solutions.

“We have gone through a digital revolution together with Dundee Precious Metals,” says Jari Moilanen, Director, Digital Solutions, Metso. “We have built the infrastructure and have implemented our ways in which we automate and optimize the unit operations of the plant - and we are seeing results.”

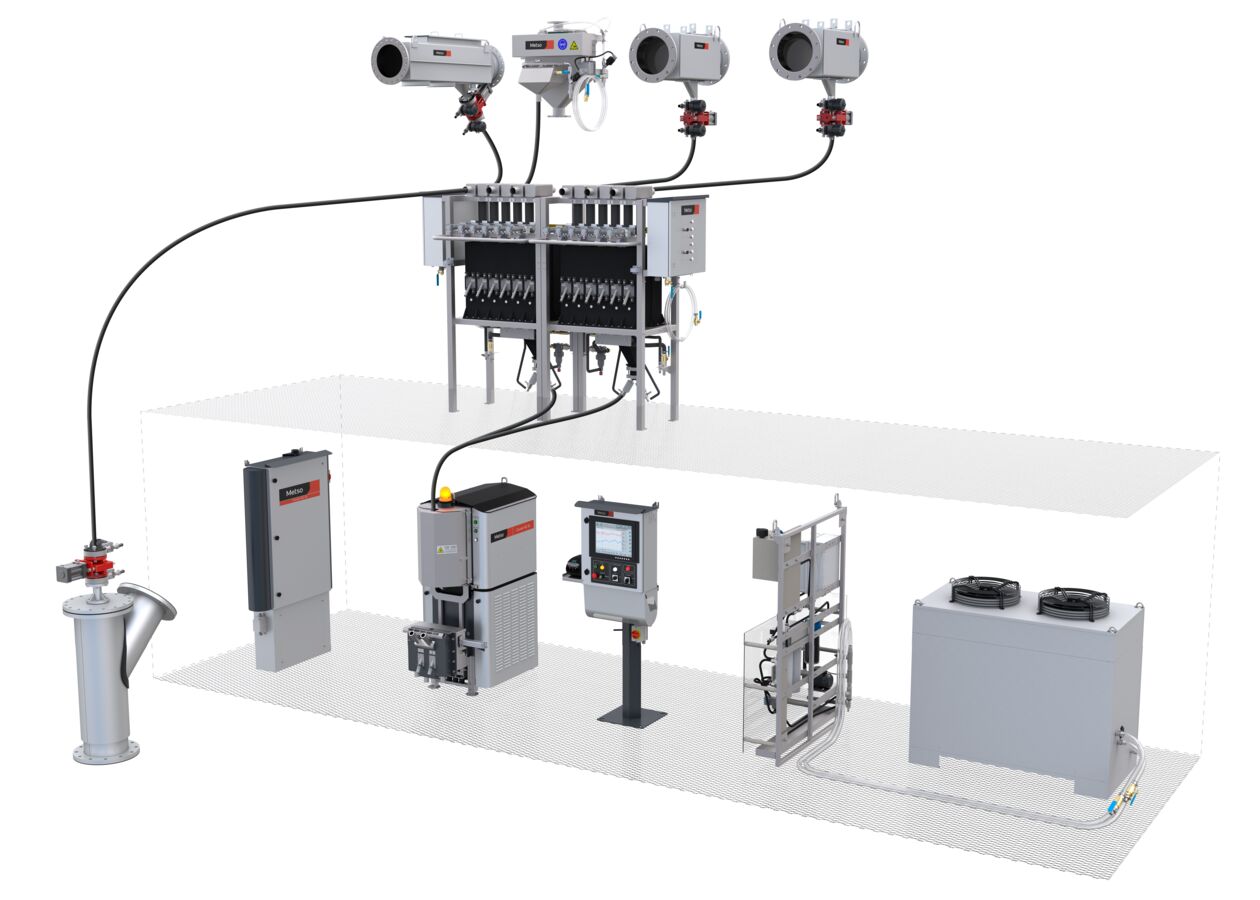

A key player in their upgraded processes has been the utilization of Metso Optimizers. The duty of optimizers is to control key variables of processes and enhance overall plant performance. For the Ada Tepe and Chelopech sites, this applies to grinding, flotation, thickening and now filtration.

"Our aims were smarter processes and informed decisions," says Desislava Sabeva, Chief Metallurgist, Dundee Precious Metals Chelopech. "Metso's expertise was crucial in achieving our operational targets."

Inspired by the success in Africa, Dundee Precious Metals reached out to Metso to see if our optimizers would work at their mining sites in Bulgaria, namely Ada Tepe (an open-pit gold mine) and Chelopech (an underground copper mine). Metso orchestrated workshops to audit the instrumentation and infrastructure to prepare both sites for seamless optimizer integration.

“The importance of optimizers cannot be understated, since they compensate for the variations that are coming from inputs to the process,” explains Moilanen. “Optimizers perform quick and time-consuming actions in a way that would be challenging for humans to replicate. So, optimizers are working with unit processes such as grinding, flotation, dewatering, thickening or filtration, and helping them adapt to the variability and run the process at given set points.”