Increasing concave segment lifetime from 6 months to 2 years

“The starting point was that we had frequent, long maintenance stops which affected the availability of the primary crusher,” says Iván Rangel, Maintenance Assessor at Milpillas.

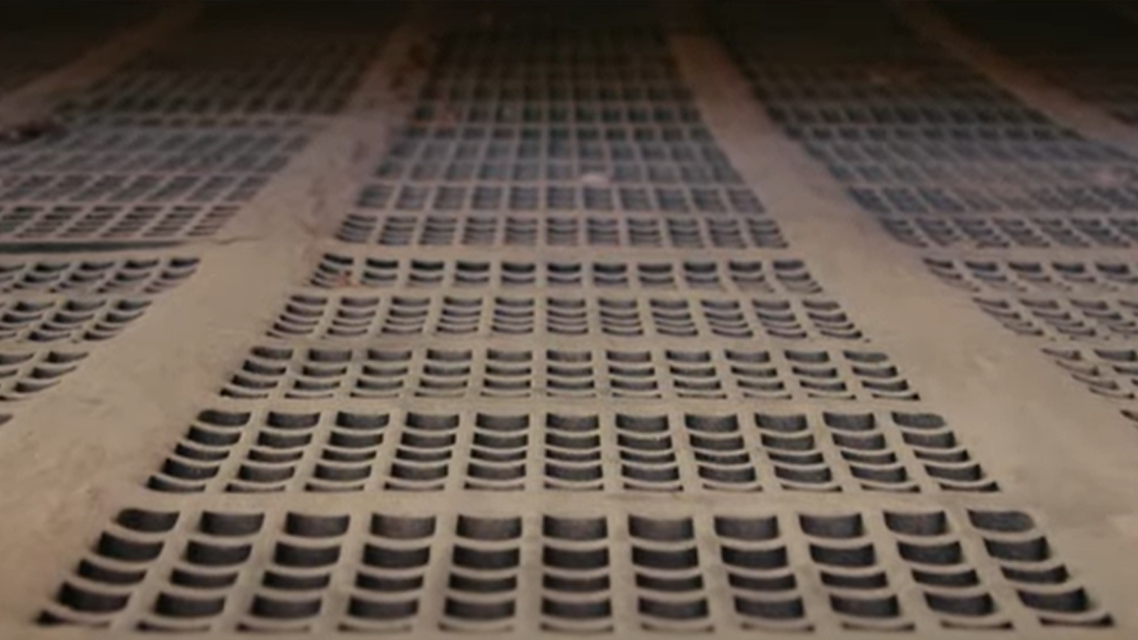

The optimization that Metso provided involved switching to a different alloy and changing the design. The wear life increased to 4 times the original.

“With these new concave segments, we have increased the crusher’s availability, and hence the processing and crushing of material in our processes. By moving from stops every six months to once every two years with the new concaves, our production costs have gone down considerably,” Iván Rangel explains.

“Lower maintenance times and fewer maintenance stops have led to greater production. Above all, and this is fundamental for our group, the maintenance staff are exposed to risk for less time,” he continues.

According to Iván Rangel, the collaboration with Metso has been a win-win situation.

“The collaboration we have had with Metso has been fundamental in reducing production costs, improving the equipment’s availability, and exposing our staff to less risk,” he concludes.