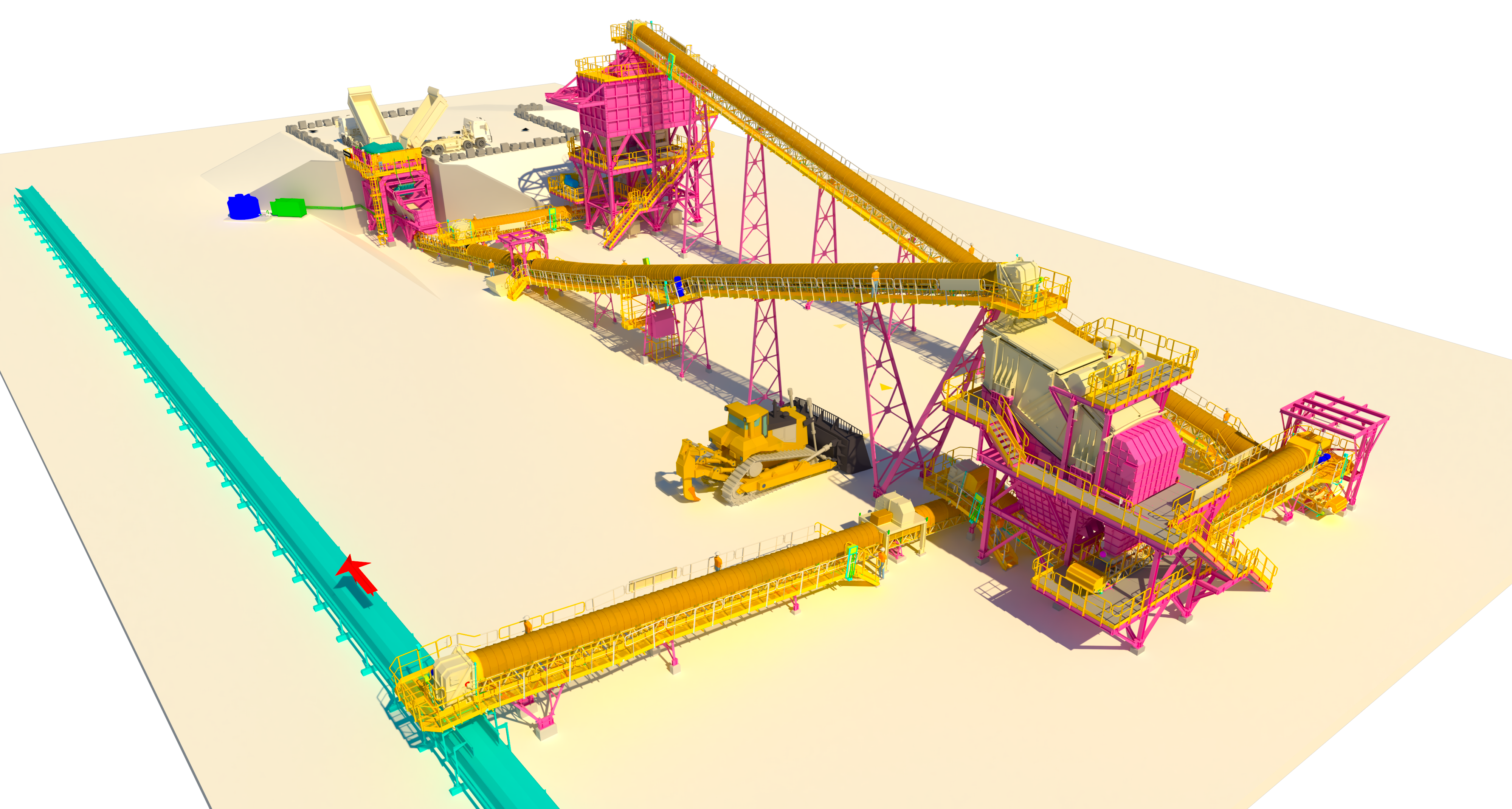

The project kicked off in 2021 when the customer approached us about a need for a new crushing and screening plant. The FIT Recrushing plant capacity had to be able to handle between 400 – 450 TPH. The application was to help the end customer to boost the SAG mill capacity in the main circuit.

The main challenge from MPM was the delivery time. The FIT Recrushing plant would process hard SAG pebble material and send the product back to the main circuit. Therefore, the sooner the FIT Recrushing would be in operation, the sooner both MPM and the end producer would start to see the benefits.

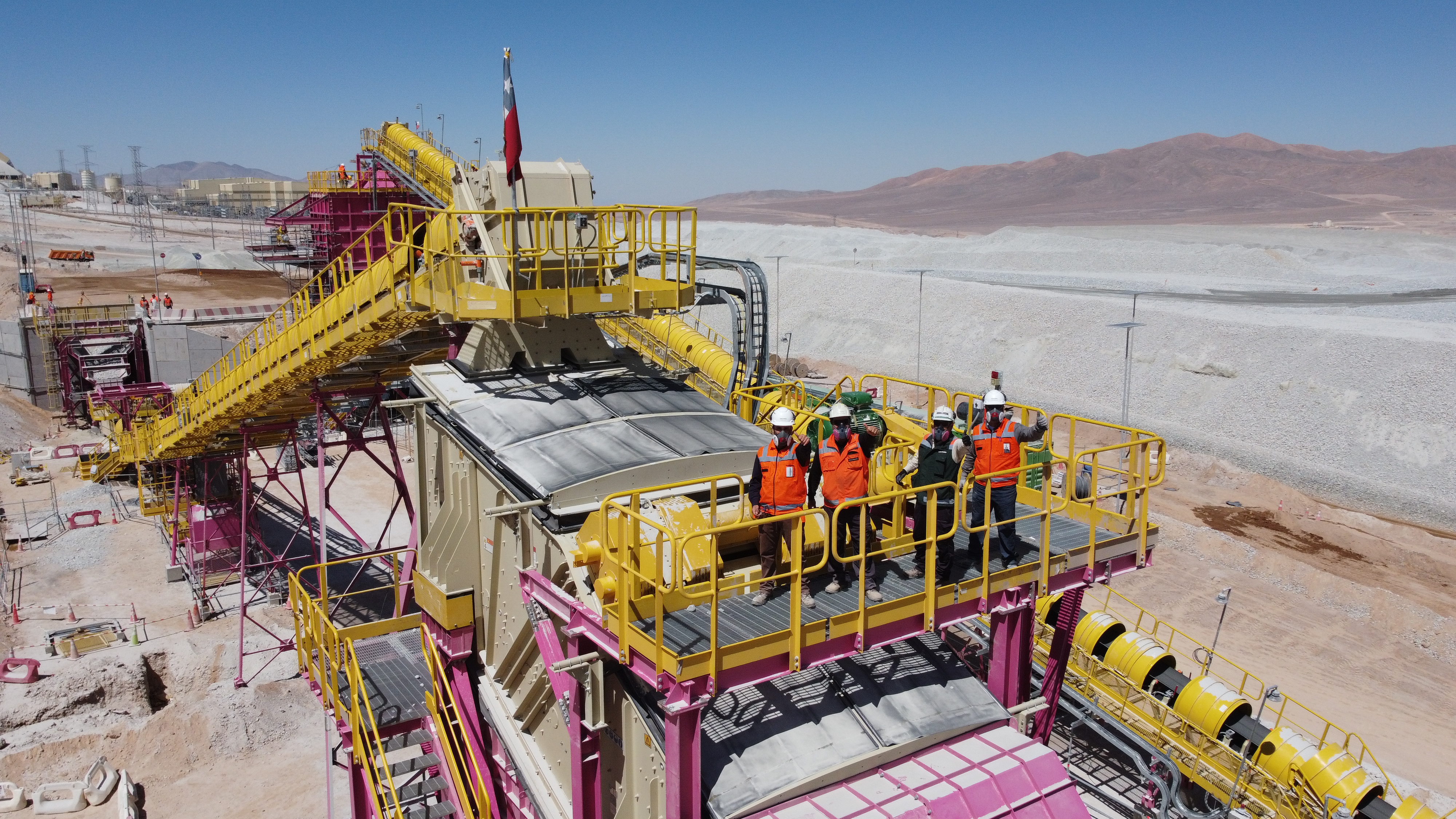

There were two additional challenges: the plant was running with a material different from what was originally specified, and the number of steel media balls coming from the SAG mill was much higher than expected. Both were limiting the efficiency of the operation.

“This was a very collaborative effort with the customer. Knowing a holistic view on the challenges they were facing was key to know exactly the optimal solution to recommend,” says Fábio Watanabe, Project Manager, at Metso Brazil.