Installation logistics and support

The Outotec workshop ensured every component, nut and bolt was organised to facilitate an efficient and seamless install. For example, items which were to be used first in the install were packed last, so they would be unpacked first at site. We also provided clearly visible and documented match marking prior to workshop disassembly, as well as detailed drawings to facilitate a study lift and erection sequencing. Packing of all components was designed to maximise ease of handling and minimize the possibility of transport damage. Comprehensive installation drawings and instructions were also provided to facilitate a speedy and seamless installation.

Quality management is key

Quality management is always key, particularly with large vessels such as thickeners. With the bolted design, quality is better controlled, as most QA is performed in the workshop. Quality management also extends to Outotec’s established systems and procedures, managing the entire process from design through to delivery and beyond.

Results

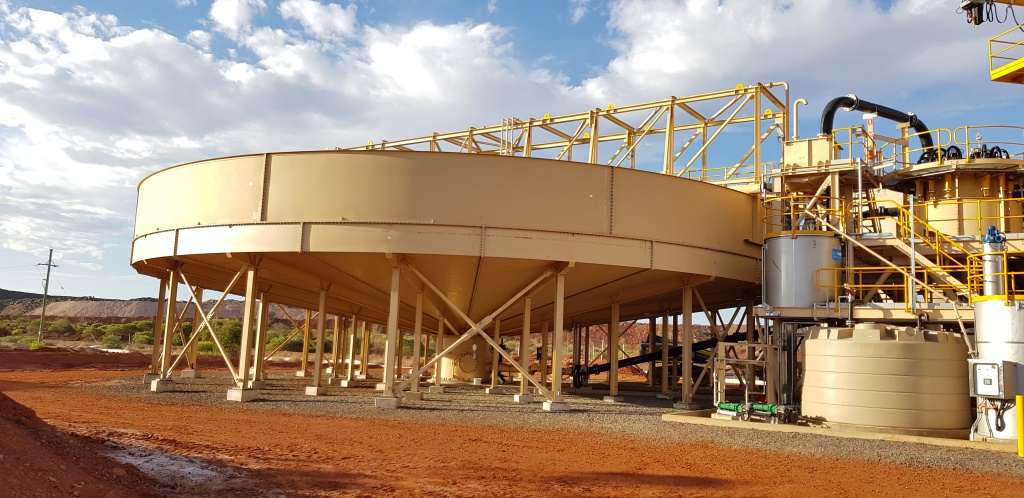

The GRES construction team, using day shift only, fully installed the thickener in just 14 days. The 26m thickener was commissioning-ready in 14 days. The pre-commissioning site check was completed in 16 hours in total.

GRES Senior Project Engineer, Matt Sala Tenna, commented “All went well. Fabrication quality, packaging and marking of all materials was good so it was easy to assemble and find parts”. The quality of the supply from Outotec and quality of Outotec IOM / install drawings was good too which helps us on site” he added.

Since commissioning, the thickener has been performing to expectations.

“The installation of this piece of equipment has allowed the processing plant to not only produce a product suitable for underground backfill but also reduce the processing plant’s lime consumption significantly” explains Cleo Leunig, Processing Manager at Carosue Dam. “The thickener has allowed a quicker return of process water back into the circuit and has reduced lime consumption by ~3kg/t” she continued.

*This case study has been written prior to the merger of Metso and Outotec.