ACT Advanced process control

The addition of the ACT advanced process control system brought stability to the process and well as consistency to the plant’s operation. Less disturbance means less variance in process performance. Higher availability leads to more efficient utilization of capital as equipment is used at full capacity all the time – while a good human operator can reach production levels close to optimal, a good system will keep production at an optimal level.

Benefits of the ACT system include:

- Increased process stability and performance

- Efficient utilization of the process

- An open and easy-to-learn system with process visualizations

- Easily interfaces and connects to all existing plant control systems

Metallurgical improvement

The plant had an ideal flowsheet offering statistics on a line-by-line comparison study displaying before and after results. The comparison study was used to evaluate the metallurgical performance which revealed a significant improvement measuring a 1.9% higher recovery of nickel and 2.1% increase in copper without effecting the grade.

Summary

Our customer’s feedback was very positive stating Outotec was a reliable and trustworthy partner from start to finish.

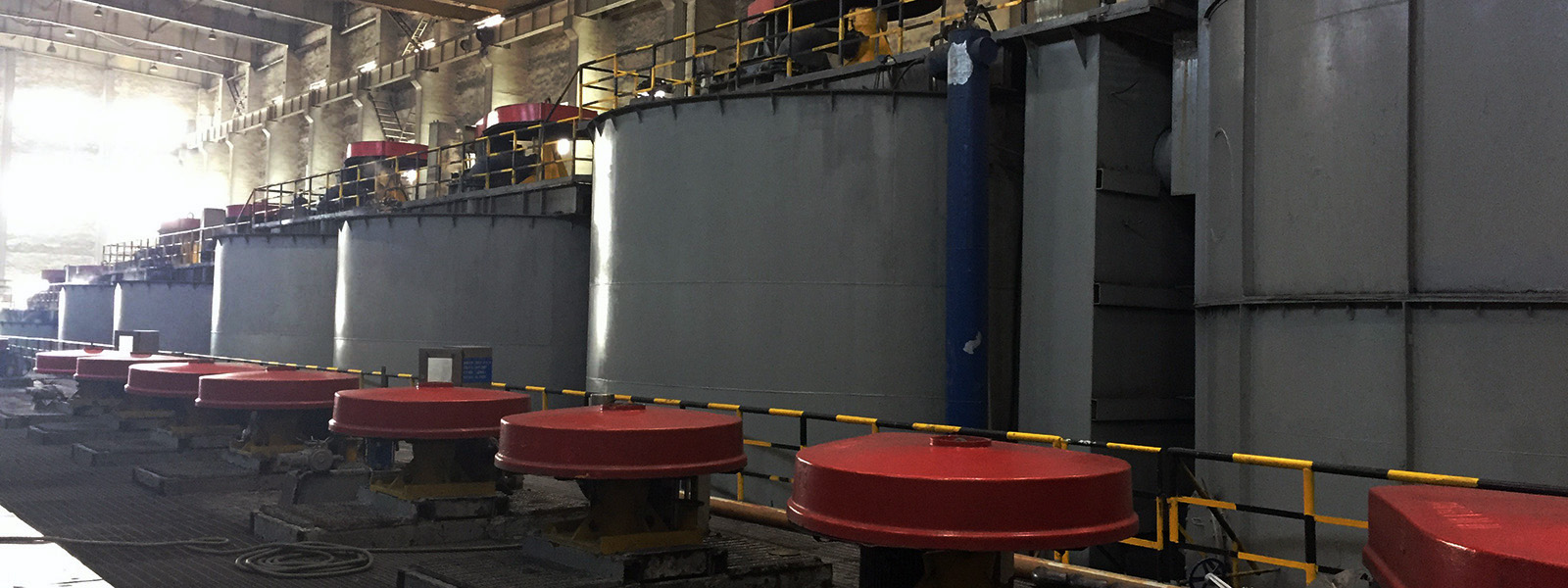

Shift operators stated they were hesitant upon installation of the frothspeed controls, but now maintain that they cannot operate without it. The maintenance foreman indicated that during the first inspection the condition of the FloatForce mechanisms we like new and are a big step forward compared to the previous mixing mechanisms.

Outotec and Jinchuan Group continue their cooperation. This is the first operational FloatForce in large flotation cells located in China, and also the first retrofit project performed on this brand and type of flotation machine globally. This is a milestone project for Outotec China and the Beneficiation business line.

*This case study has been written prior to the merger of Metso an Outotec.