Background

During the copper smelting process, it is common for a certain amount of copper to be lost to slag. In order to minimise this loss, the slag is further treated to recover the valuable metal. One treatment method is via froth flotation in a Slag Flotation Plant.

With its smelter operational for many decades, one customer recently replaced its slag flotation plant to further optimise metals recovery. Outotec has already worked closely with the customer over many years, with its smelting, refining, anode casting and process control technologies all used at this particular site.

Slag Flotation Plant

The slag from the customer’s smelter furnace is processed at the Slag Flotation Plant (SFP) via various minerals processing technologies. The SFP plays an important role in extracting maximum value from the ore. In 2016, during the early installation phase of the customer’s new SFP, Outotec undertook a Maintenance Assessment with the aim of proposing a performance-based maintenance solution.

Complete maintenance solution

Outotec was subsequently awarded the contract for the maintenance of the SFP. Initially a two-year contract, it commenced in November 2016. Equipment scope comprises a primary crusher, SAG mill, ball mill, regrind mill, floats, thickeners, and filters, along with conveyors, pumps and automation. All equipment is non-Outotec.

Scope

The scope of the performance-based maintenance agreement reflects the customer’s long term commitment to best practice OH&S and plant performance. Outotec’s maintenance agreement, for example, includes the disciplines of management and leadership, maintenance, reliability, planning and scheduling, continuous improvement, and health and safety. Central to this agreement are Key Performance Indicators (KPIs) with jointly agreed targets in OH&S, productivity, and maintenance management.

Performance-based agreements = shared risk

This performance-based maintenance model at the customer’s site uses a fixed monthly price plus a KPI-based bonus/penalty model. Such a model not only gives our customer peace of mind in the budgeting process but also allows for shared risk in the implementation of necessary actions to achieve performance levels.

This shared-risk service agreement, designed to reduce costs and improve the effectiveness of maintenance operations, is a true ‘win-win’ partnership. Outotec’s technical knowledge and maintenance management add value by enabling customers to focus on their core competencies and maintain their competitive edge.

Customers also have access to business processes and tools for management of the plant, including, for example, continuous improvement methodology and reliability management. The Outotec team continuously measures and evaluates the site’s practices and performance relative to global best practice standards. This allows the team to identify gaps, pinpoint improvement and propose actions to deliver results.

Maintenance team

The on-site team consists of a site manager, reliability engineer, planners, health and safety representatives as well as skilled personnel in electrical, instrumentation, fitting, welding and an on-site medic. Maintenance of the SFP is 24/7, 365 days a year, with Outotec plant maintenance covering both day and night shifts.

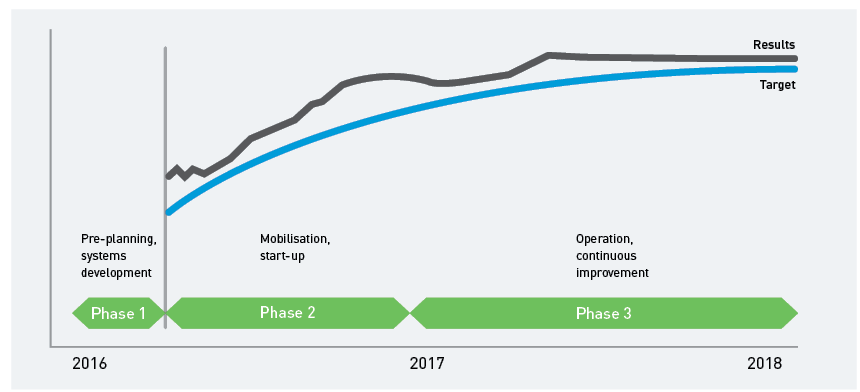

A systematic phased approach

Our maintenance of the customer’s SFP is delivered by a systematic, phased management and maintenance team. It consists of three main phases: pre-planning and systems development, mobilization and start-up, and operation and continuous improvement.

Phase 1 – pre-planning, systems development

During the 1st phase, the operational and strategic maintenance plans are created. It is important to have a long term action plan to deliver sustainable success. The CMMS system is configured and populated with items such as maintenance tasks, equipment trees, criticality levels, maintenance plans, standard work instructions and spares/inventory data set-up. From a personnel perspective, suitable local maintenance sub-contractors are identified as well as the necessary preparation for health and safety, staffing, planning, and training. Specialists within Maintenance and Reliability, IT, Supply Chain and Human Resources support the preparations.

Phase 2 – mobilization, start-up

The second phase focuses on the establishment of our team on-site and includes inductions, training in maintenance practices, implementation of key maintenance management processes including communication, reporting, performance management, continuous improvement and Root Cause Analysis (RCA).

Phase 3 – operation, continuous improvement

Following the startup and initial mobilization phase at site, continuous improvement of the site’s maintenance activities is now center stage. With the right approach, systems, and people in place, the probability of unexpected downtime is greatly reduced. Early Root Cause Analysis (RCA), Continuous Improvement (CI) and action planning are an ongoing focus of the Outotec maintenance team.