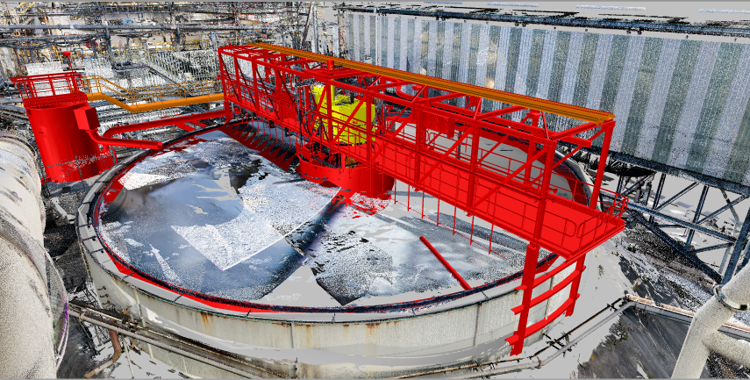

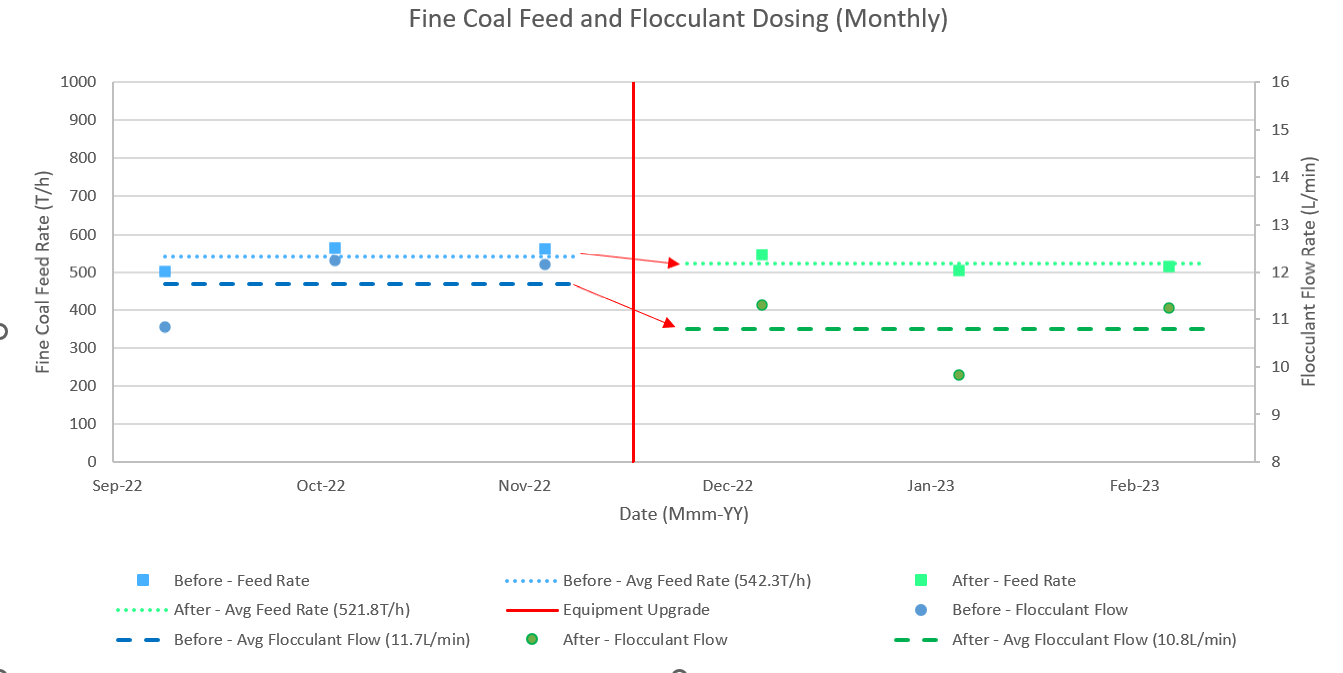

A thickener upgrade, as well as modernisations within the feed system, has been successfully implemented at a metallurgical coal site in New South Wales, Australia. The plant plays a vital role in producing high-quality hard coking coal for steelmaking. One of its essential processes involves thickeners, which are utilized in coal product and tailings thickening duties. These thickeners have a significant impact on water and energy consumption, as well as adjacent processes.

Benefits

- Improved thickener control and performance

- Improved reliability

- Increased flotation reagent dosing flexibility

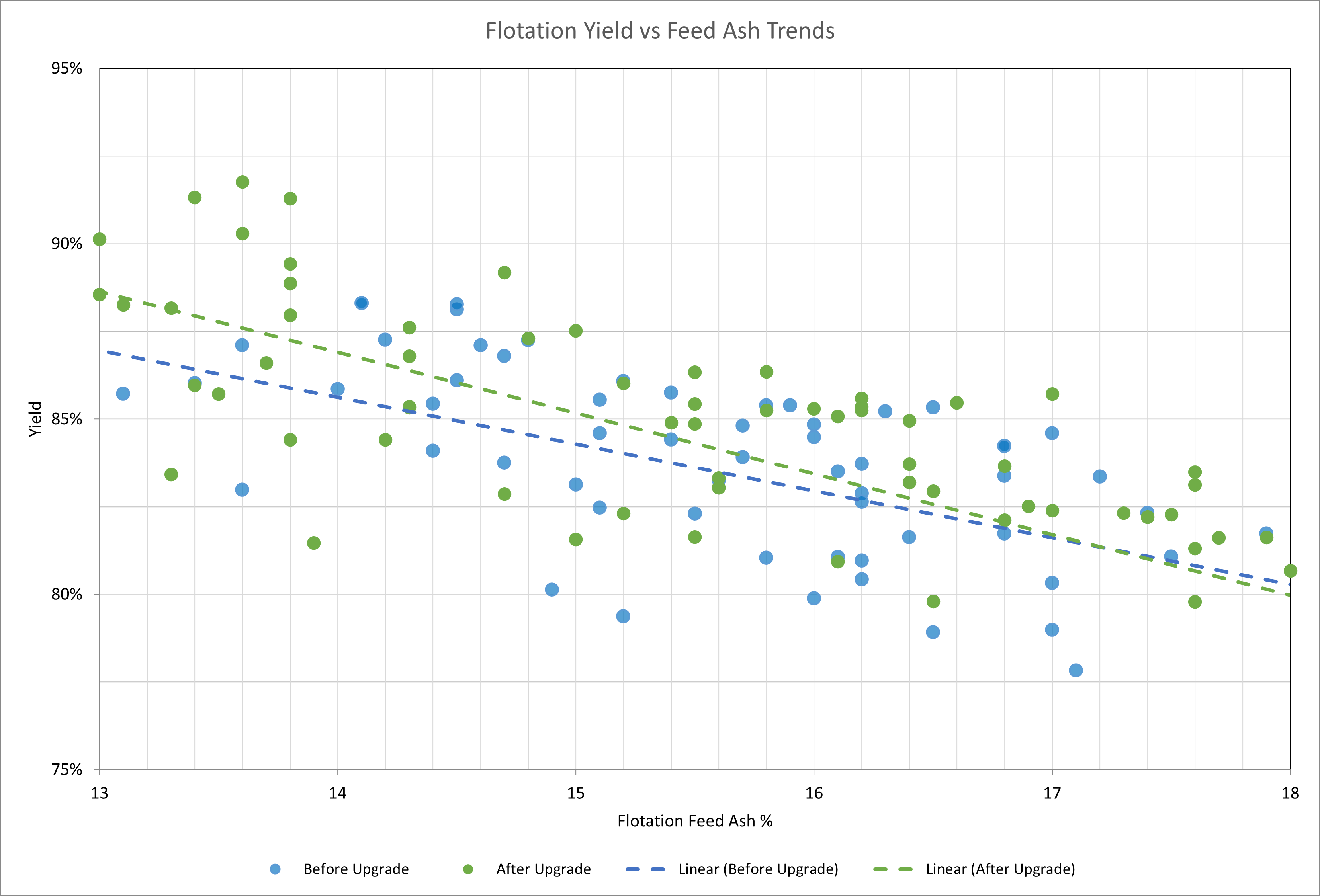

- Reduced froth loading

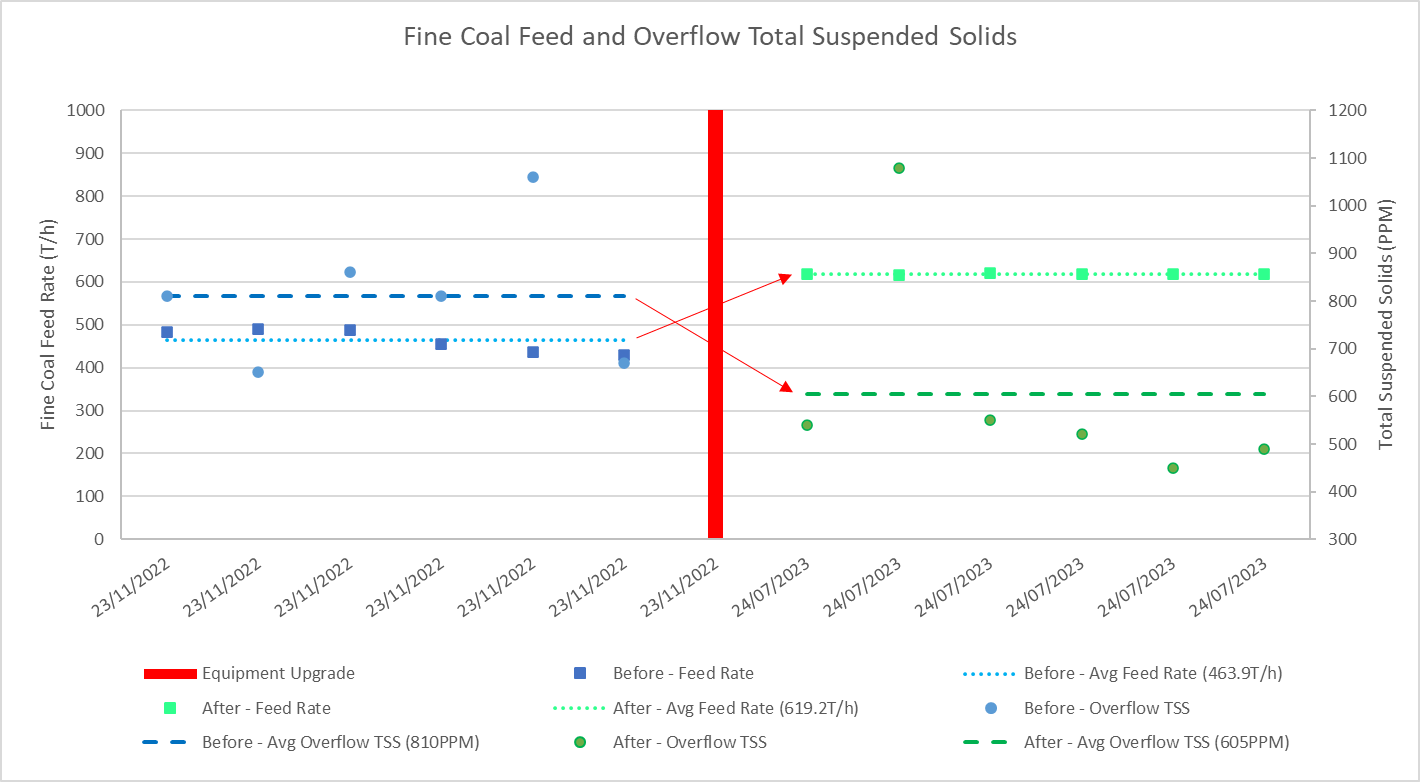

- Better overflow clarity

- Improved thickener operational stability

- Increased safety and sustainability

- Reduced wear

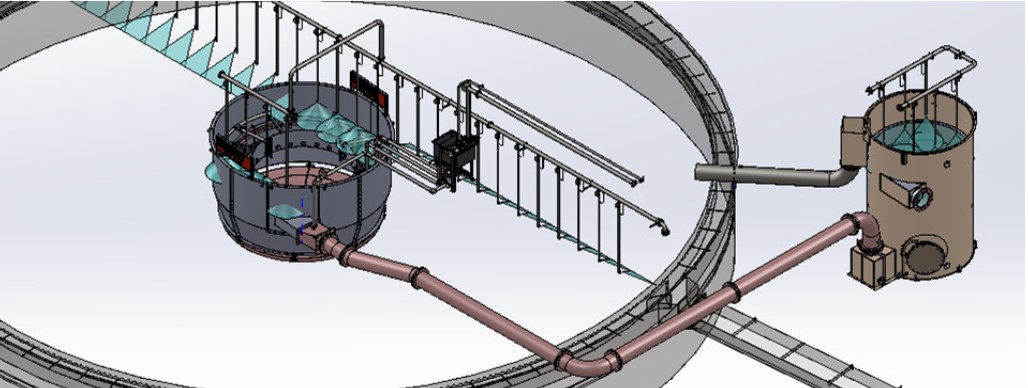

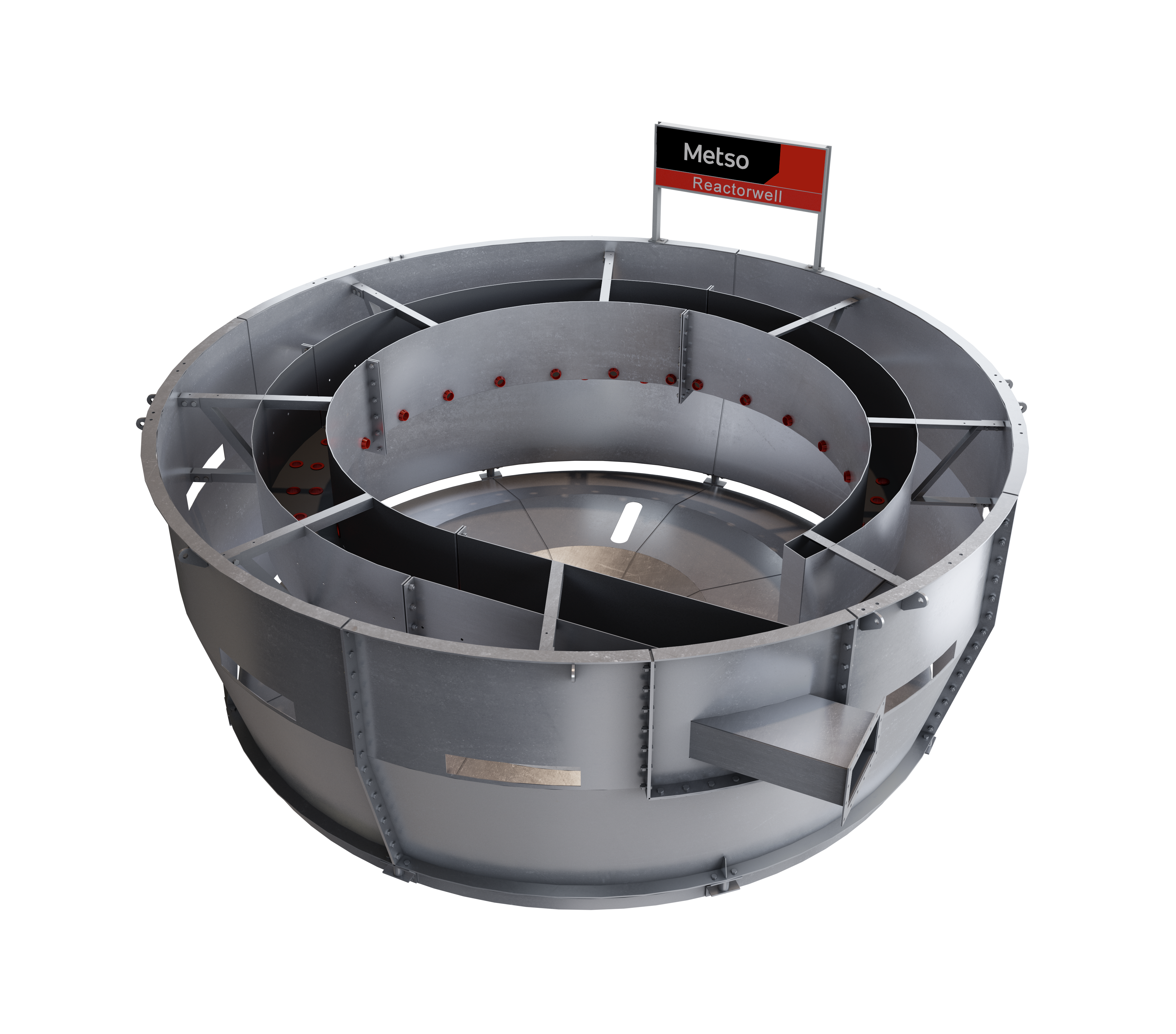

In today’s world, water is becoming an increasingly scarcer and more valuable resource. Thus, the importance of reliable and high-performing thickener technology continues to grow. In addition to that, as society moves towards circularity and reducing waste, the re-use of existing installed equipment through modernization and upgrades is becoming increasingly important in the world of minerals processing. These growing demands ultimately prompted the site to utilize Metso’s vast experience and knowledge to complete a thorough assessment and upgrade of their existing equipment. While the initial focus was asset end-of-life management and reliability, Metso’s meticulous audit identified significant potential performance enhancements, such as modifications to the feed system, the inclusion of an external thickener feed tank, and more.