The refurbishment included new hydraulic cylinders to handle plate compression, cake discharge, plate opening and closing, and pressure control. These functions are crucial for achieving efficient solid-liquid separation and cake removal and ensuring continuous and reliable filter operation.

Real-time monitoring of each cylinder was implemented to detect misalignment and prevent breakdowns by proactively stopping the filter. Since installation, no misalignment alarms have been triggered, resulting in increased availability from 60-70% to over 95%.

In 2022, a second filter retrofit and upgrade were conducted with the same scope as the previous one, allowing for interchangeable parts among all the filters. The first installation was done in collaboration with the customer, whereas the second retrofit was conducted by Metso on an advisory basis based on all the mine operator’s experience and training gained from the first retrofit.

Operator training was also provided to familiarize the customer with the functioning principles of the VPA filter. Maintenance practices have been adjusted due to the improved wear life of the parts and reduced maintenance requirements.

More functionality and automation with filter upgrade

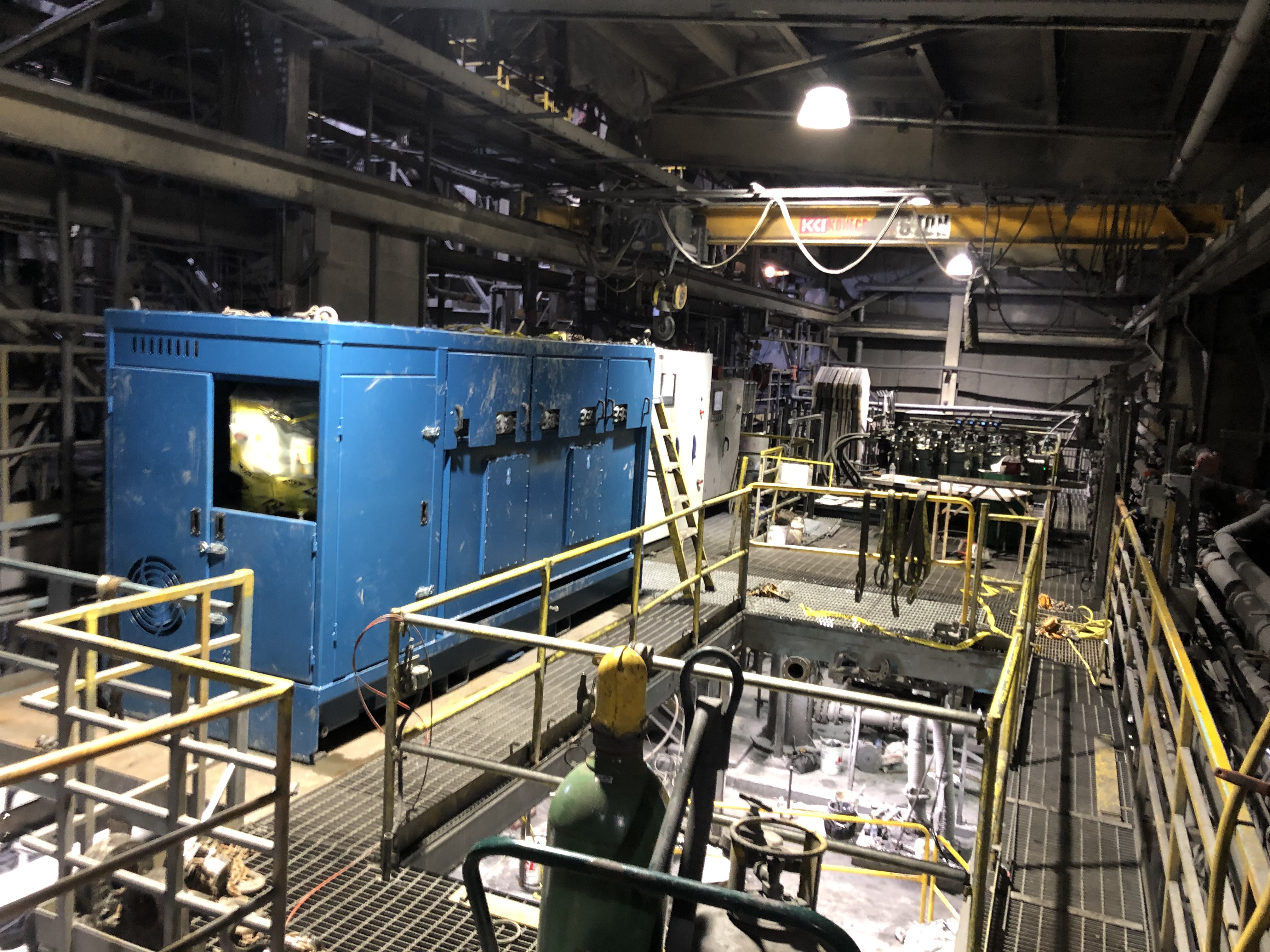

The filters were also upgraded with modern technology for additional functionality and automation. A Programmable Logic Controller (PLC) was installed to ensure precise control, reliable operation and safety by monitoring, controlling and automating various filter functions.

Another addition to the filter was a new generation Hydraulic Power Unit (HPU) which is responsible for generating hydraulic power, maintaining pressure control, integrating with the filter's control system, optimizing energy efficiency, monitoring performance and ensuring safety. The new HPU requires half the amount of oil than the older units, making it more environmentally friendly. It plays a vital role in enabling efficient and reliable operation of the VPA filter for effective solid-liquid separation.

Position sensors were also incorporated to monitor pressure, contribute to automation and control and provide valuable data for analysis and performance evaluation. These functions help improve the efficiency, productivity and reliability of the VPA filter.

The retrofit and upgrade project was completed with zero harm according to the highest safety standards.