Suitable for greenfield and brownfield upgrade applications offering improvements and performance of precipitation tank and seed storage tank

Used to increase yield, reduce cost and safety risk, and improve operational security

Has been implemented in number of mixing tanks globally since 1990s

Benefits

We can retrofit existing precipitation tanks and seed storage tanks with the latest swirl flow agitation technology to help you resolve issues like heavy scale growth, ineffective solids suspension during stop-starting, or sediment build-up, bogging at the tank bottom, lower agitator life – significantly improves process performance and reduces maintenance costs and time compared to existing conventional agitation equipment while increasing suspension availability and sustainability.

- Enhances solids suspension, reduced sedimentation

- Increased throughput

- Increased natural cooling

- Increases suspension time

- Lower capital Investment & low maintenance cost

- Reduce energy up to 10% (according to slurry concentration)

- Reduced scaling-, erosion-, wear-rate, less mechanical failure

- Less pump failure caused by sedimentation, air entrainment

- Equipment lifetime extends up to 20 years

- Easy restart after power failure

- No need for personnel to enter the tank for agitator maintenance

Features

- Simplified agitator engineering: short shaft, no internal structures

- Lower tip speed

- Less scaling, less sedimentation, erosion, wear

- Robust agitator design and match for your process

- Increased solids loading

- Increased solids suspension time

- Up to 1 million US$ saved for each 10 years, comparing with draft tube de-installing /replacement with new equipment

- Proven design through over 25 years operation practice in plants

- Applicable for any geometry of tank bottom: cone, flat, etc.

The swirl flow agitator unit is suitable for several applications including: precipitation tanks, seed storage tanks, and acid tanks used in the Alumina refinery process.

Innovative basic features

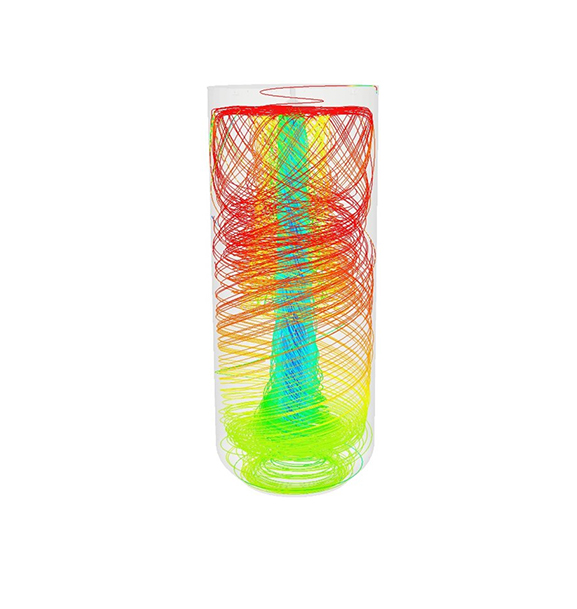

Compared to conventional agitation technology Swirl Flow precipitation increased operating factor and tank volume, and the low conversion cost makes it the preferred option over replacement of a damaged draft tube.

The most common process problem occurring with precipitation is scales on the agitator as well as tank inner wall, sedimentation and bogging at the tank bottom, which may cause damage of the agitator, worn out and have a severe impact on process uptime and increase maintenance times. Bogging can be prevented by using the Metso swirl flow agitator. We offer agitators as an upgrade, modifications for the existing tank and for the new agitator.

Scope

The following scope is an example and may vary depending on your case:

- Test work and engineering

- Delivery the swirl flow agitator solution

- Delivery including matched driving system: motor, gearbox, VFD, agitator

- Optional support structure or modifications to existing structure

- Existing agitator upgrade, modification

- On-site services

- Advising on Installation and commissioning

- Process advisory services