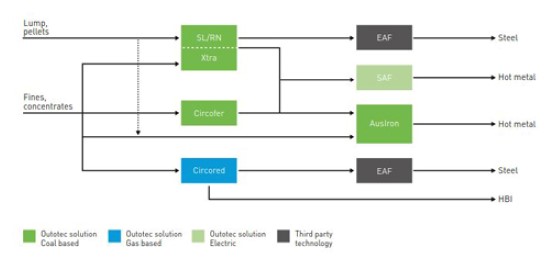

Our direct and smelting reduction offering covers:

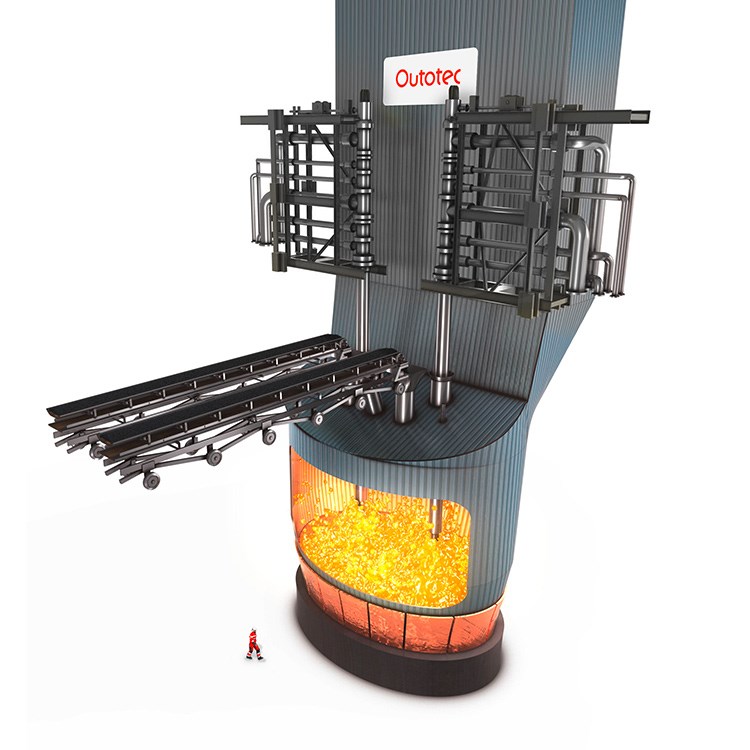

- Design, engineering, delivery, and services for traditional SL/RN direct reduction plants based on a rotary kiln, with non-coking coal as the reductant and fuel.

- Design, engineering, delivery, and services for SL/ RN-Xtra plants, which use a combination of a pre-hardening grate and traditional SL/RN kiln for the treatment of iron ore fines.

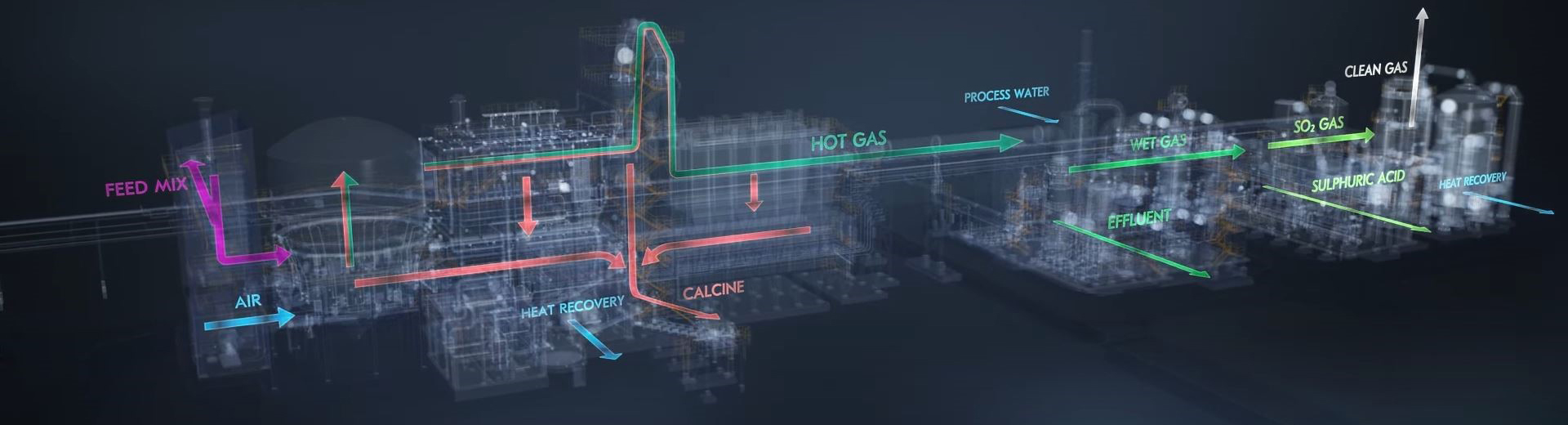

- Hydrogen-based Circored fine ore reduction plants with both circulating (CFB) and bubbling (BFB) fluidized bed reactors.

- Services for our shaft-furnace direct reduction plants built by Outotec based on a Midrex® license.