Read the customer case:

How Metso leading-edge SX-EW technology is helping to maximize RoI at the world’s largest SX facility, Grupo México’s ESDE III copper SX-EW plant

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

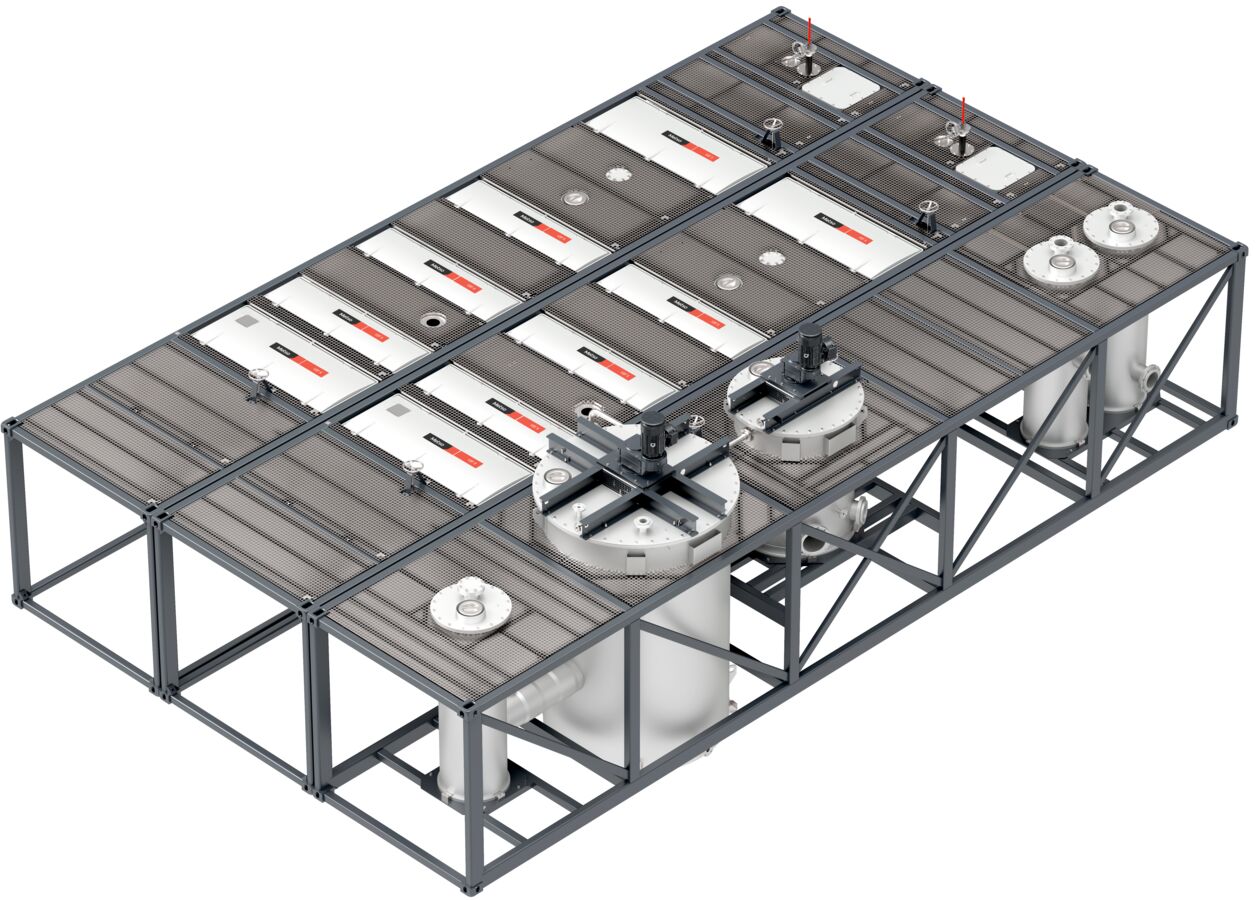

World’s largest Cu SX plants use Metso VSF® SX technology

Minimized volatile organic compounds emissions & energy consumption

20% reduction in lead time with less on-site installation work

With the growing demand for higher purity metals, the increasing use of new metals such as battery metals, and the need for lower operation and investment costs, together with more reliable and environmentally friendly process, solvent extraction process is gaining wider ground in hydrometallurgy applications.

Today, around 25% of the world's copper is recovered by solvent extraction, which has been found to be the most cost-effective method of producing high-quality cathode material.

For nearly 40 years, Metso has been developing its wide range of solvent extraction technologies, delivering both equipment and processes to its customers. Our VSF (Vertical Smooth Flow) plants offer lower lifetime costs, significantly shorter lead times, and sustainable life-cycle technology built on decades of experience in solvent extraction. Metso is the only technology provider that offers a highly predefined but still tailor-made total delivery package based on your needs.

In the solvent extraction process phase, metal in the pregnant leach solution (PLS) is concentrated and purified into electrolytes. The pure electrolyte is then used in electrowinning to produce a chemically and physically high-quality product.

Core benefits:

Metso offers optimised solutions and complete plants for the production of high-quality copper cathodes through innovative leaching, solvent extraction and electrowinning technologies. Metso technology package for solvent extraction plants may contain basic and/or detailed engineering as well as proprietary and key equipment supply.

|

CORE |

ENABLERS |

SERVICES |

|

Crud treatment Unit SX plant core basic engineering

|

DispersionSense (view inside SX settlers) Ventilation gas scrubbers Instrumentation |

Spares Startup Troubleshooting Flowsheet development and studies Kinetic batch testing of leaching

|

We collect and process your data on this site to better understand how it is used. You can give your consent to all or selected purposes or decline the non-essential ones. Essential cookies, which are necessary for the basic website functionality such as page navigation, cannot be declined. Without these cookies, the website would not function properly. For more details, please refer to our Privacy Notice.

Privacy Notice