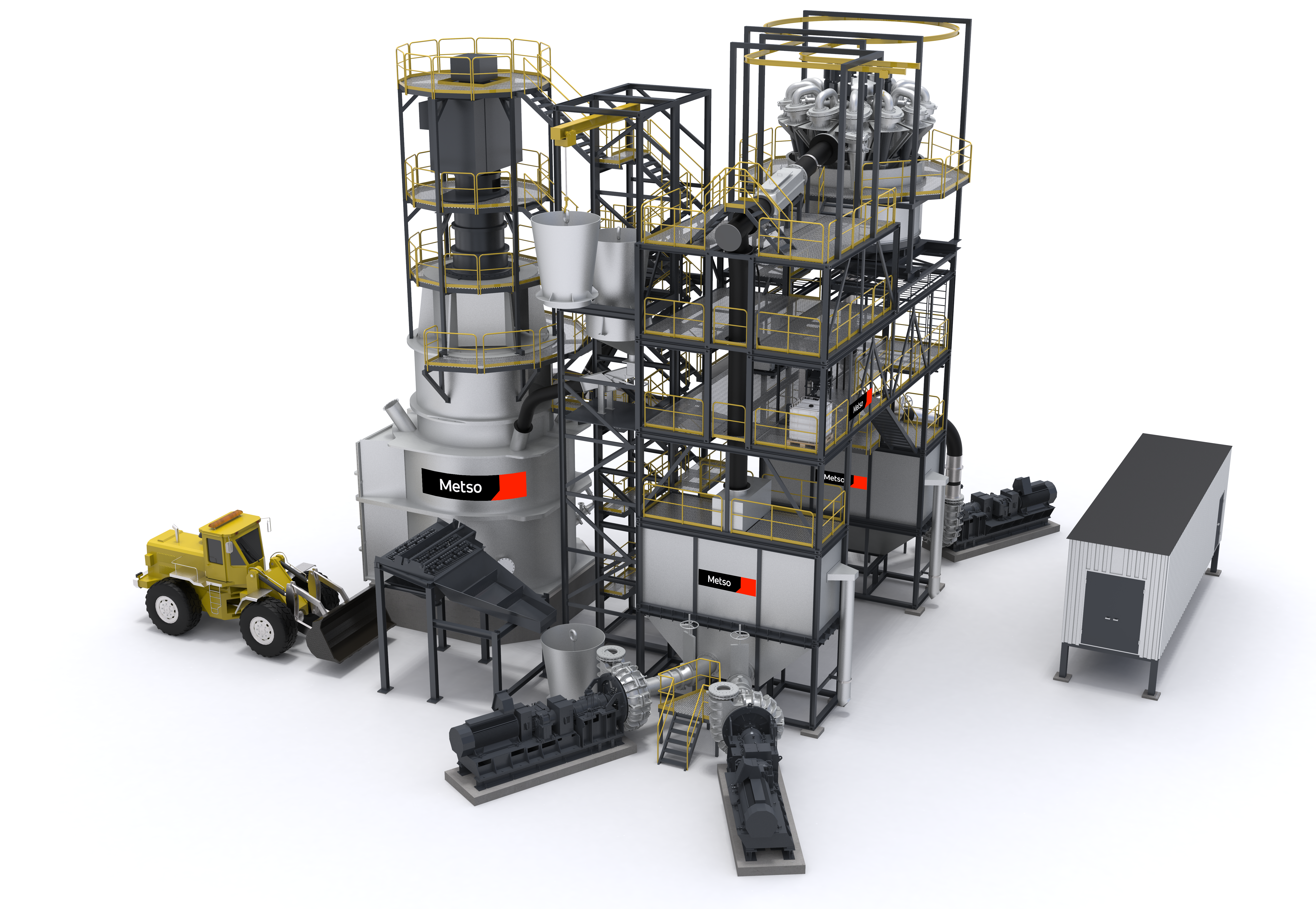

Ideal for grinding finer products, stirred mills are known for their energy efficiency and compact design, reducing floor space requirements. These mills are based on gravity-induced and fluidized technologies, allowing for the optimum equipment solution for all comminution circuits covering secondary, tertiary, fine, ultrafine, regrind, and lime slaking applications.

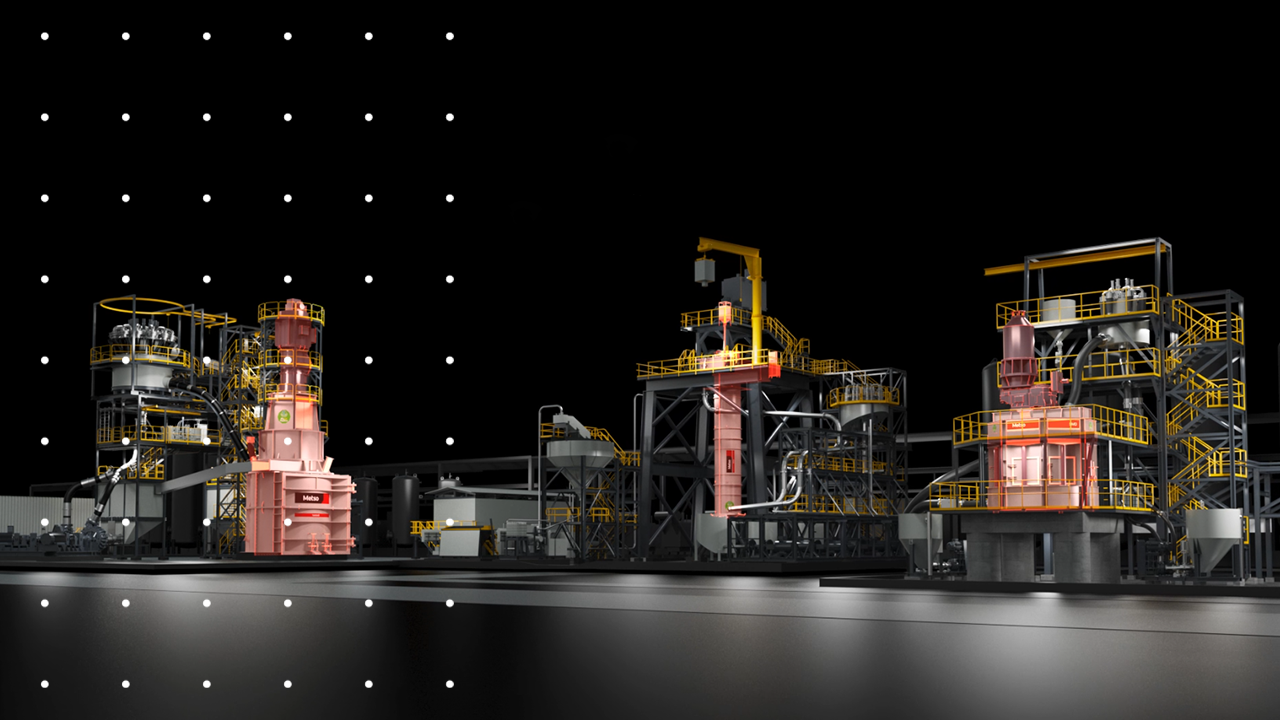

Metso offers a wide portfolio of stirred milling technologies: Vertimill®, HIGmill™, and Stirred Media Detritor (SMD).

The Metso stirred mills are suitable for a large range of product sizes. The standardized range includes chamber units of up to 50,000 liters and the world’s largest industry units with up to 6,500 kW of installed power. Floor space use is optimized, which reduces investment costs, and installation is easy. All our stirred mills are part of the Metso Plus product portfolio, thanks to the sustainability benefits they deliver.

Mature by performance

Metso stirred mills continue to be the industry leader in performance and exceed expectations. With our energy efficiency, increased uptime and reduced plant footprint, find CAPEX and OPEX advantages compared to similar stirred milling technology. Even for brownfield applications, we make integration simple and quick.

Unique by experience

Metso has over 50 years of experience in testing, innovating and delivering stirred mills technology. This includes over 500 installations worldwide in diverse applications from an industry-leading portfolio.

Unmatched services offering

Metso not only delivers the mill that will optimize your operation but is with you from installation to the end of the mill lifetime. With a comprehensive parts and services offering, always expect maximum performance.