Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

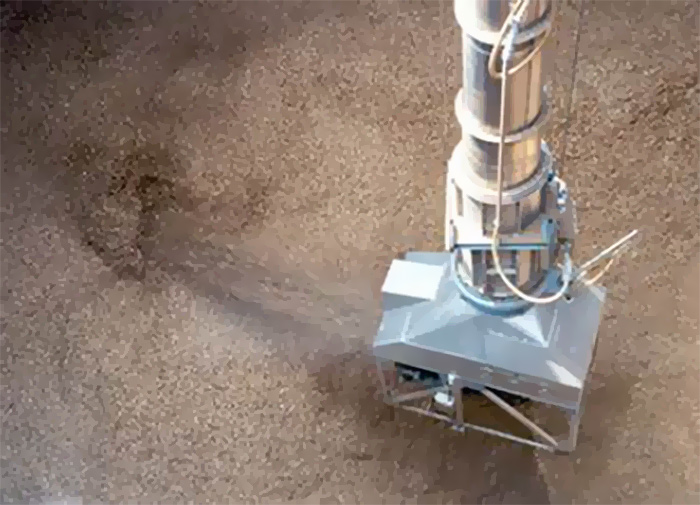

Ship trimmers and throwers are the ideal method for uniform loading into a ship’s hold or increasing your stockpile capabilities with their short endless belt that operates over two pulleys driven at high speed. A pair of idler discs form a conveying arc. A chute directs material onto the belt at the rear slope and material travels around the short conveying arc pressed against the belt by centrifugal force. Material leaves the belt as a high speed stream. Their swivel joint allows them to pivot and cover a large loading or stockpiling area.

Portal centrifugal-action bulk material pilers are also available which handle materials brought to one point that can be stockpiled in a wide range of heights and distances. Portable pilers eliminate the need for overhead conveyor structures. Storage piles can be created indoors or outdoors with one compact, portable machine.

Common use cases:

Trimmers and throwers are used for shiploading, stockpiling, and container loading.

Applicable industries: