How it works

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

Robust design and construction

Minimum working parts

Main drives comprise long travel, harrow, barrel rotation and conveyor

Speed variables

Special design to handle sticky material

Automatic operation, if required

Low maintenance due to minimum working parts

Durable and dependable

Maximum possible homogeneity of material properties and particle size distribution in the resultant blend

Better blending

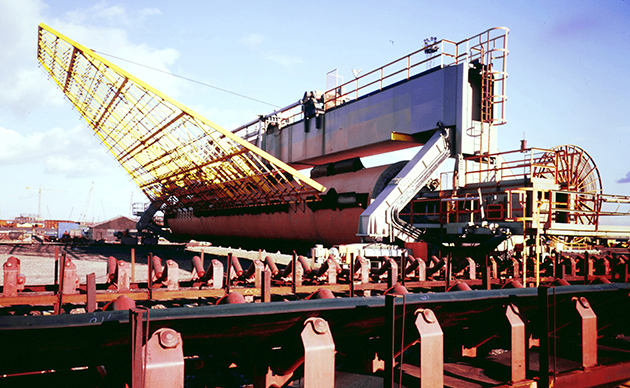

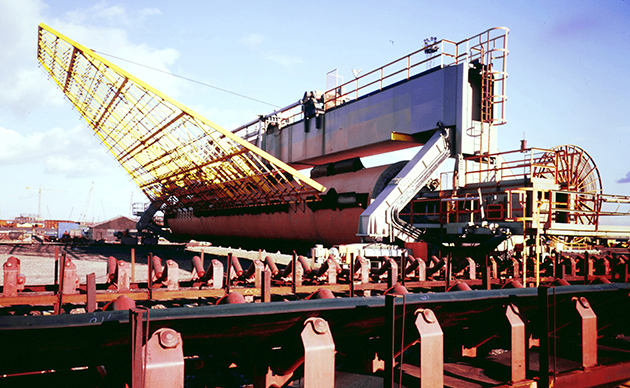

A barrel reclaimer comprises of a bridge spanning the stockpile which is supported on “A” frames at each side, these are carried on motor-driven bogies which run on rails laid on each side of the pile. The heart of the machine is a rotating barrel supported from the main structure. This barrel is fitted with a large number of reclaiming buckets arranged along its length and around it circumference, which pick up the material that has been fed to the base of the pile by means of a harrow which traverses across the pile face. The oscillating rake system disturbs the material in the stockpile across its entire width causing it to slide down the slope of the stockpile into the path of the rotating buckets.

Material collected in the buckets is discharged in a layered stream onto a belt conveyor contained within the barrel, and is then delivered to a downstream conveyor running alongside the stockpile.

Where the plant layout dictates an in-line pile arrange, bi-directional machines can be provided. In these, the barrel drive is reversible and buckets are oriented to suit either direction of rotation. In addition, a harrow is provided on each side of the machine.

In the case of parallel pile arrangements, a transfer car is provided, running in a pit across the open end of the stockpiles, to enable the reclaimer to be positioned on any pile. Alternatively, the machine may be equipped with slewing bogies to permit transverse travel on rails laid at ground level. Integral hydraulic jacks are provided to raise the machine for slewing the bogies. With this design, the need for the transfer car and its pit are eliminated.

Bulk ports and terminals

Coal-fired electric power stations

Cogeneration plants

Cement plants

Sulphur and phosphate terminals

Fertilizer plants

Woodyards

Transfer facilities

Any facility where efficient stockpile management and reclaiming of raw materials is essential.