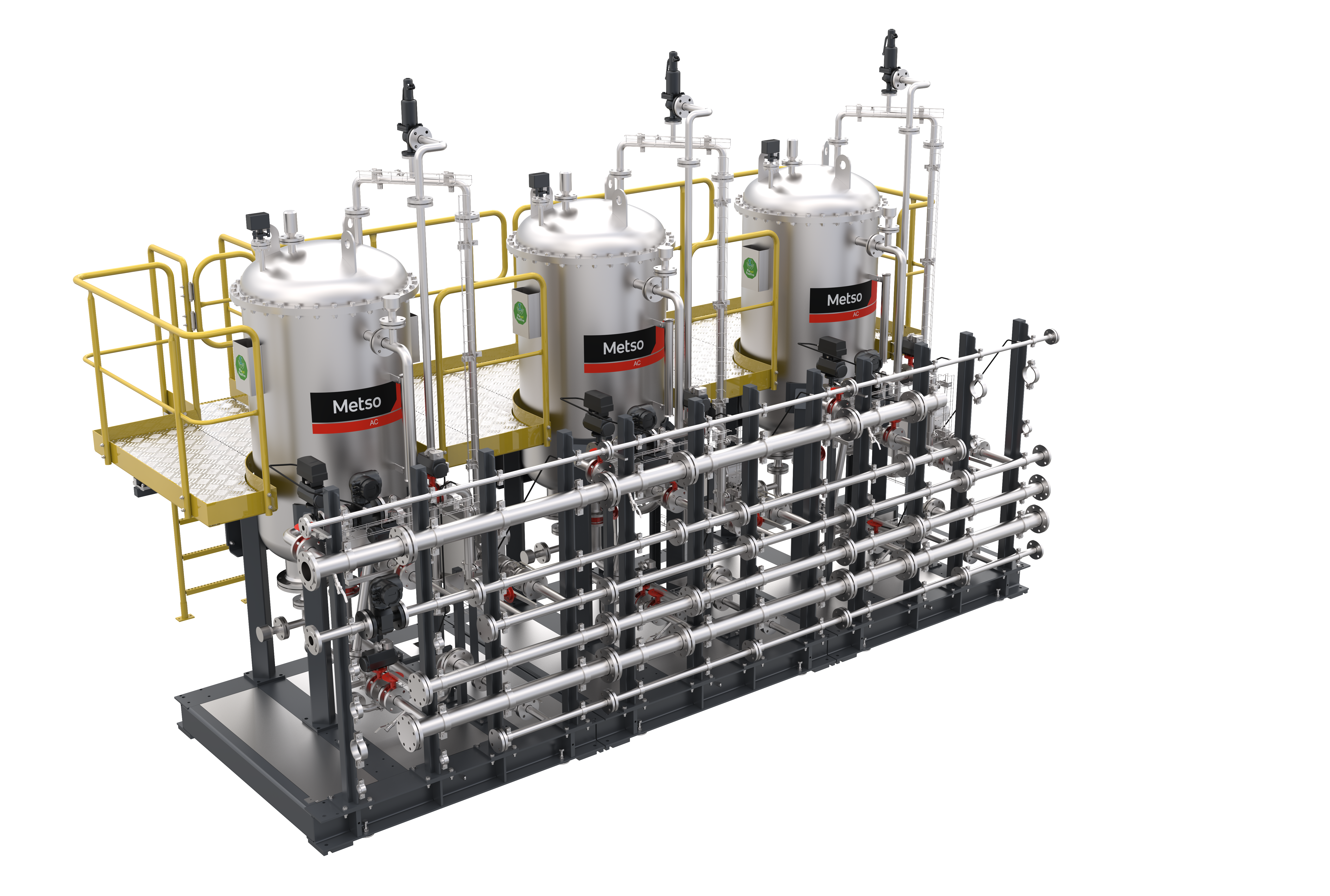

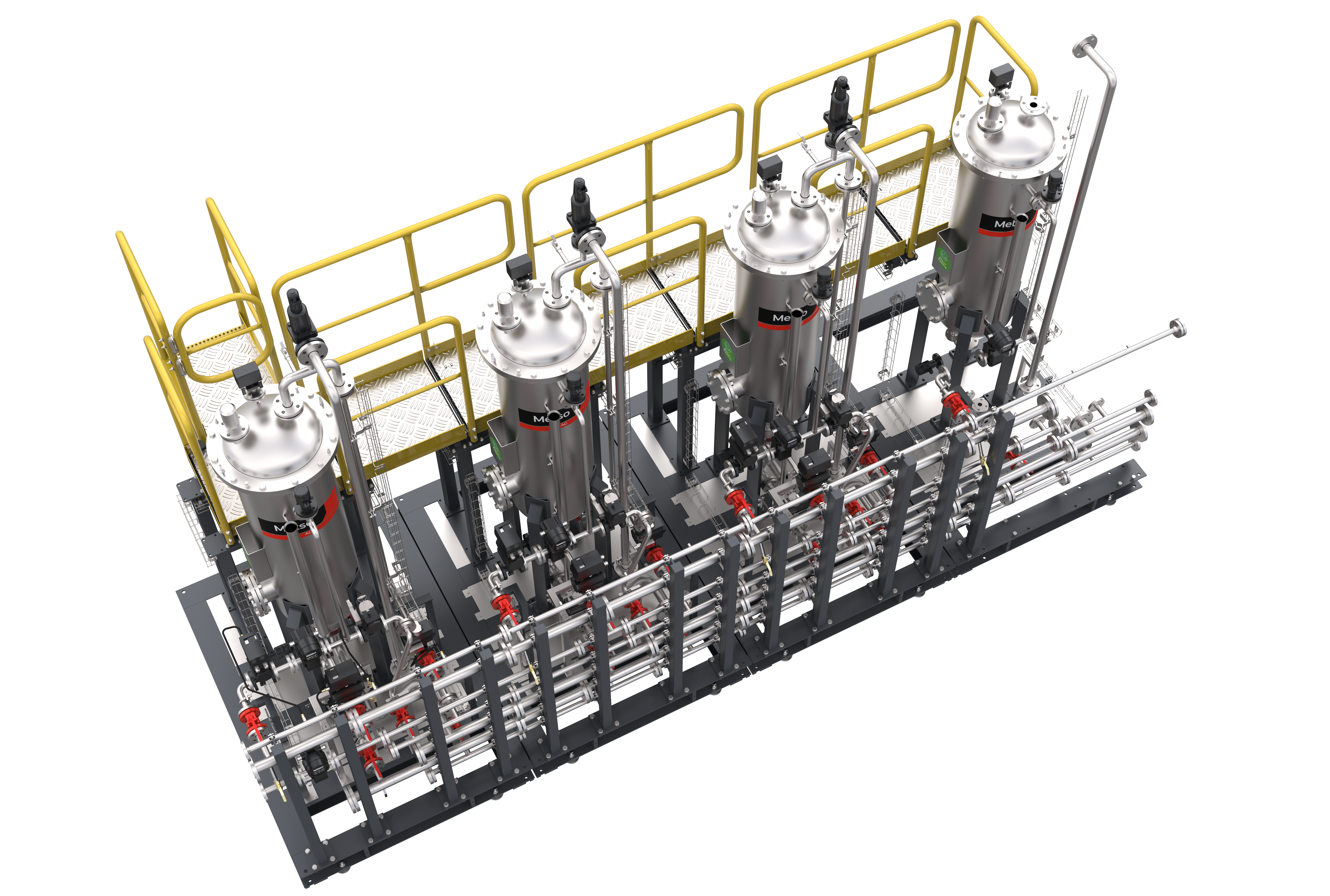

4 different filter sizes

Low operating pressure, low operating cost

Up to 15% less energy usage due to low operation pressure and lacking of moving parts

Up to 90% reduced water consumption due to use of filtrate in filter back wash

- Utilizes the already proven cost-effective, modular design and operation philosophy as in the Metso DM filter product family

- Low energy consumption due to low pumping pressure

- Increases the quality and intake of the plant’s end product

- Suitable for both greenfield and brownfield operations

- Increases recovery and recycling of valuable process chemicals

- Safe to use and operate due to sealed pressure vessel and piping

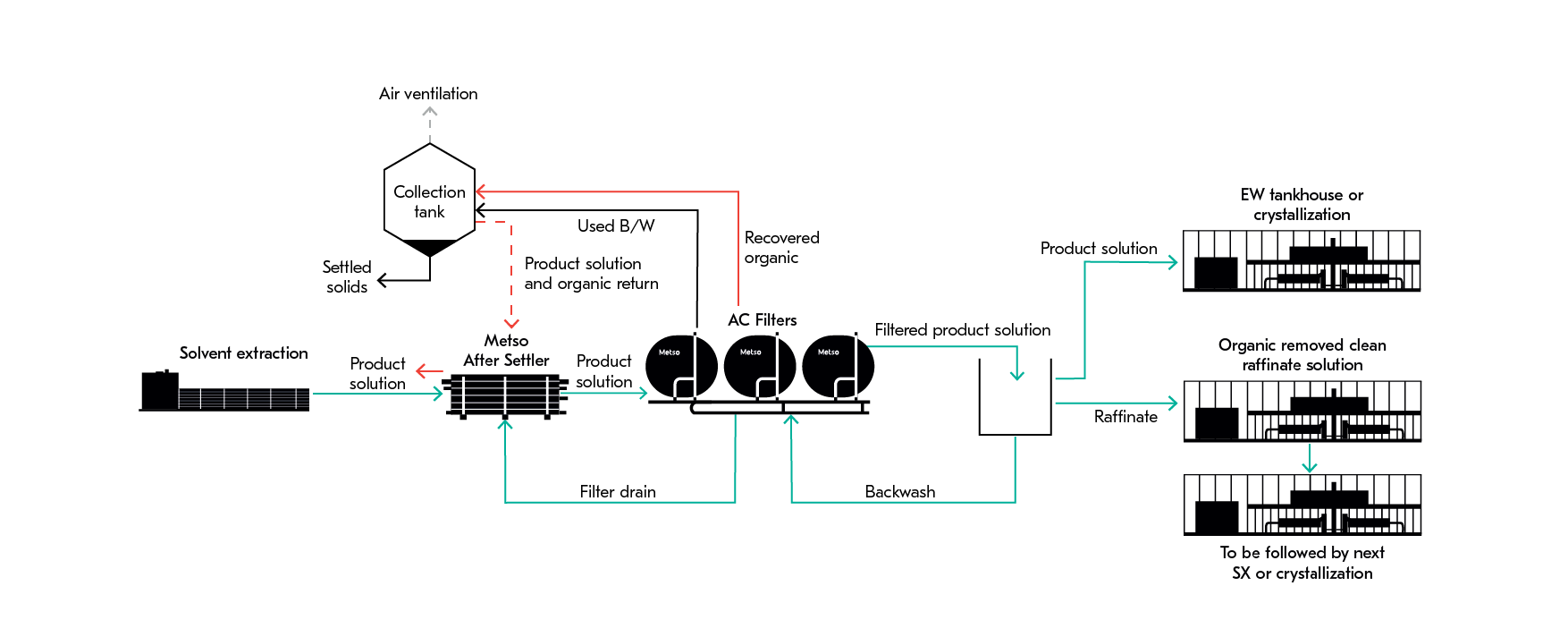

AC filter is used to remove organics in battery metals processes. It strengthens the existing Metso filtration portfolio with the capability to serve a larger variety of industries and processes. Together with the Dual Media (DM) filter, Metso now has a complete filtration portfolio for solvent extraction (SX), electrowinning and crystallization processes.

AC filter becomes an ideal choice when the solution is already free from suspended solids and when a very clean solution filtrate is needed. It is also used for raffinates, when a very clean solution is needed to follow SX steps in order to ensure that the remaining solvents and reagents from previous extraction step do not pass to the following step.

Metso’s filtration expertise is built on almost one hundred years of R&D and process knowledge, and is supported by the company’s globally unique Dewatering Technology Center (DTC) in Lappeenranta, Finland. The DTC plays a crucial role in Metso’s filtration solution innovations and acts as a hub for close university cooperation related to separation technology research. Metso has performed over 14,000 filtration tests and has delivered over 5,000 filters around the world.