Reaching your sustainability targets?

Find out how our flotation, thickener and analyzer services help to achieve your sustainability targets

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

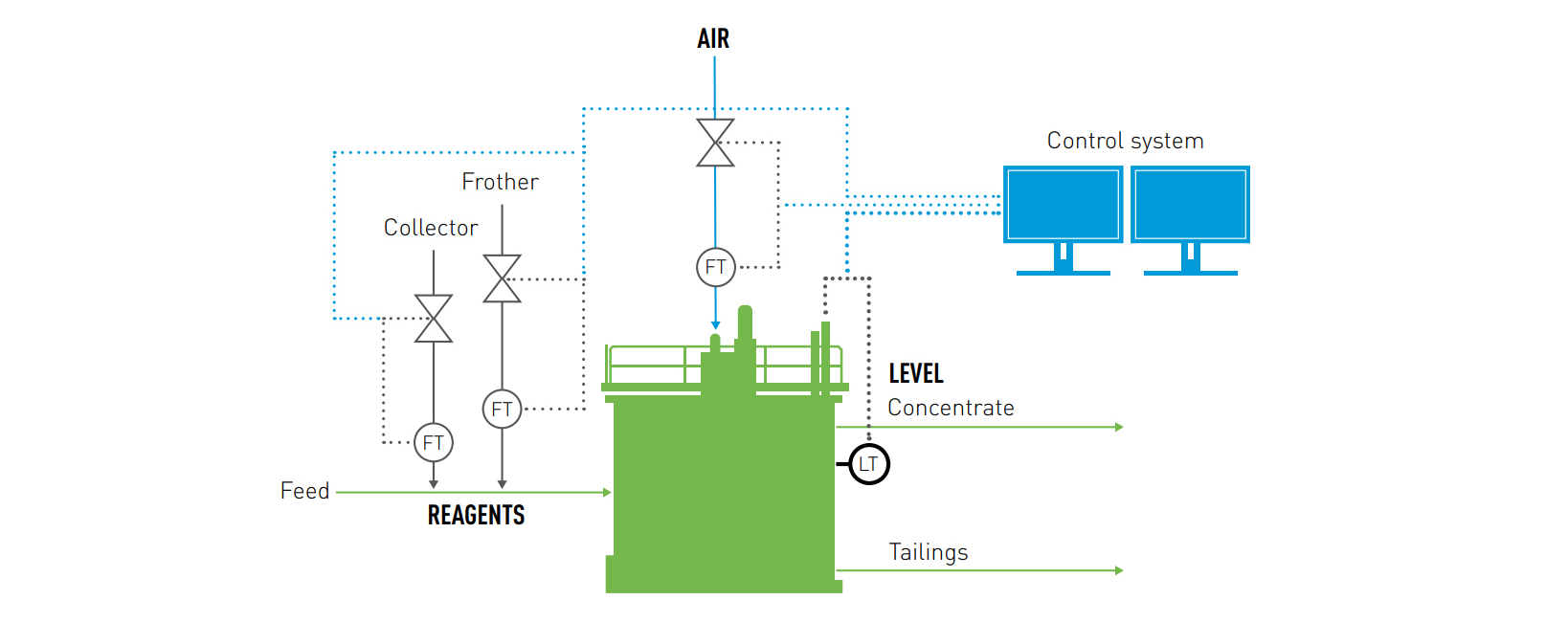

Automatic airflow adjustments

Balanced airflow control

Automatic airflow metering & valve control

Calculate superficial gas velocity & peak air recovery

A common challenge in flotation is that operators do not have sufficient time to continuously adjust the flotation air feed to ensure optimal circuit performance. Manual air regulation is difficult if there are no flow meters available to indicate the amount of air being fed into the cell, and adjusting the airflow based on the observed bubble properties requires skilled personnel, who may not be available if staff turnover is high.

The amount of airflow directly affects flotation performance and so has a major impact on the metallurgical recovery and grade of the concentrate. In addition to bubble/particle interaction, air also helps to control the speed at which concentrate is removed from the cell.

Increasing the air feed produces more bubbles, leading to a greater probability of bubble/particle interaction, which in turn leads to higher recovery overall. However, too much air can lower the concentrate grade and also result in more water being carried out of the cell in the froth layer due to faster-rising bubbles.

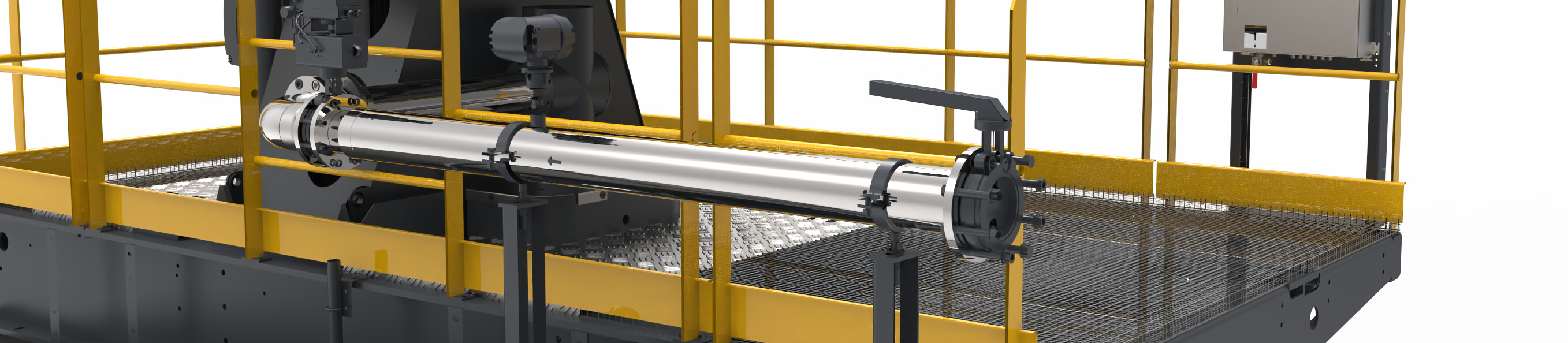

Metso Air Control Upgrade makes operators’ work easier by enabling automatic control of the flotation cell air feed. Airflow is controlled by an air mass flow meter and automatic airflow valve. The meter records the airflow rate through the feed pipe, comparing it to the set point (SP) value, and then relays the information to the automatic control valve, which adjusts the flow according to the SP.

QUESTION |

ANSWER |

| Will I still be able to control the air feed manually if I need to? | While the upgrade brings substantial benefits in terms of achieving production and quality targets, you will still be able to manually control the air feed if necessary. |

| How is the optimal airflow rate determined for each cell? | It is possible for a Metso expert to determine the optimal airflow setpoints. Alternatively, the optimal rate can be determined using our advanced control systems, taking into account production targets and other process variables such as froth level or mass pull. |

| Is it mandatory to use Metso experts and systems when implementing the upgrade? | No, support from Metso experts using our advanced control system is an optional part of the upgrade. |

| Do I need separate air control for every single cell? |

We recommend modernizing all your cells with a separate air control. However, for older Metso models like the OK-38 and OK-16 cells, a single control can be used for two or three cells simultaneously

|