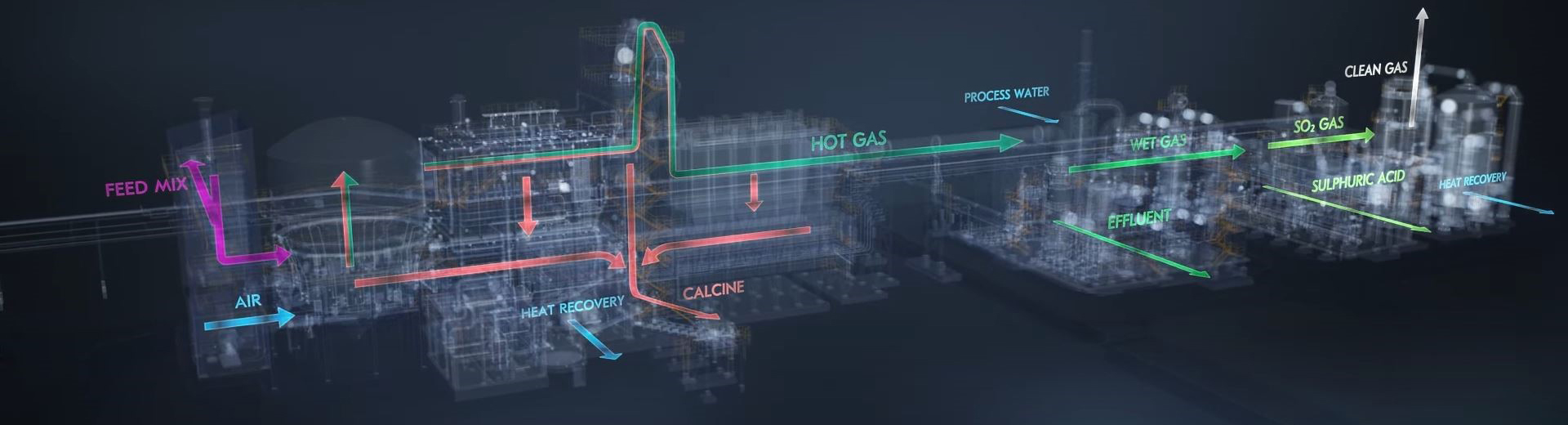

Our refinery concept has been developed through continuous R&D and covers the entire Bayer process, offering everything from pre-feasibility to EPC project implementation of process islands. We design a completely customized solution based on your specific needs that will minimize both upfront capital investment and lifetime operating costs. Our integrated refinery solutions are ideal for both greenfield projects and the expansion and optimization of existing brownfield operations.

- Integrated process design approach

- Combination of technologies tailored to suit your specific ore composition

- Optimal integration of all process islands and equipment

- Optimization of closed circuit based on an in-depth understanding of the process

- Alumina refinery offering

- Test work and concept studies for alumina characterization and project scoping

- Pre-feasibility studies

- Basic and detail engineering

- Project implementation

- Expansion studies, upgrade studies, and implementation

Based on a fully integrated refinery design to suit your specific requirements, we can deliver solutions for the following process steps in red-side, white-side, and ancillary areas:

- Bauxite enrichment

- Grinding

- Pre-desilication

- Digestion

- Sand separation and washing

- Red mud separation and washing

- Red mud treatment and disposal

- Security filtration

- Precipitation and hydrate classification

- Evaporation

- Organic control

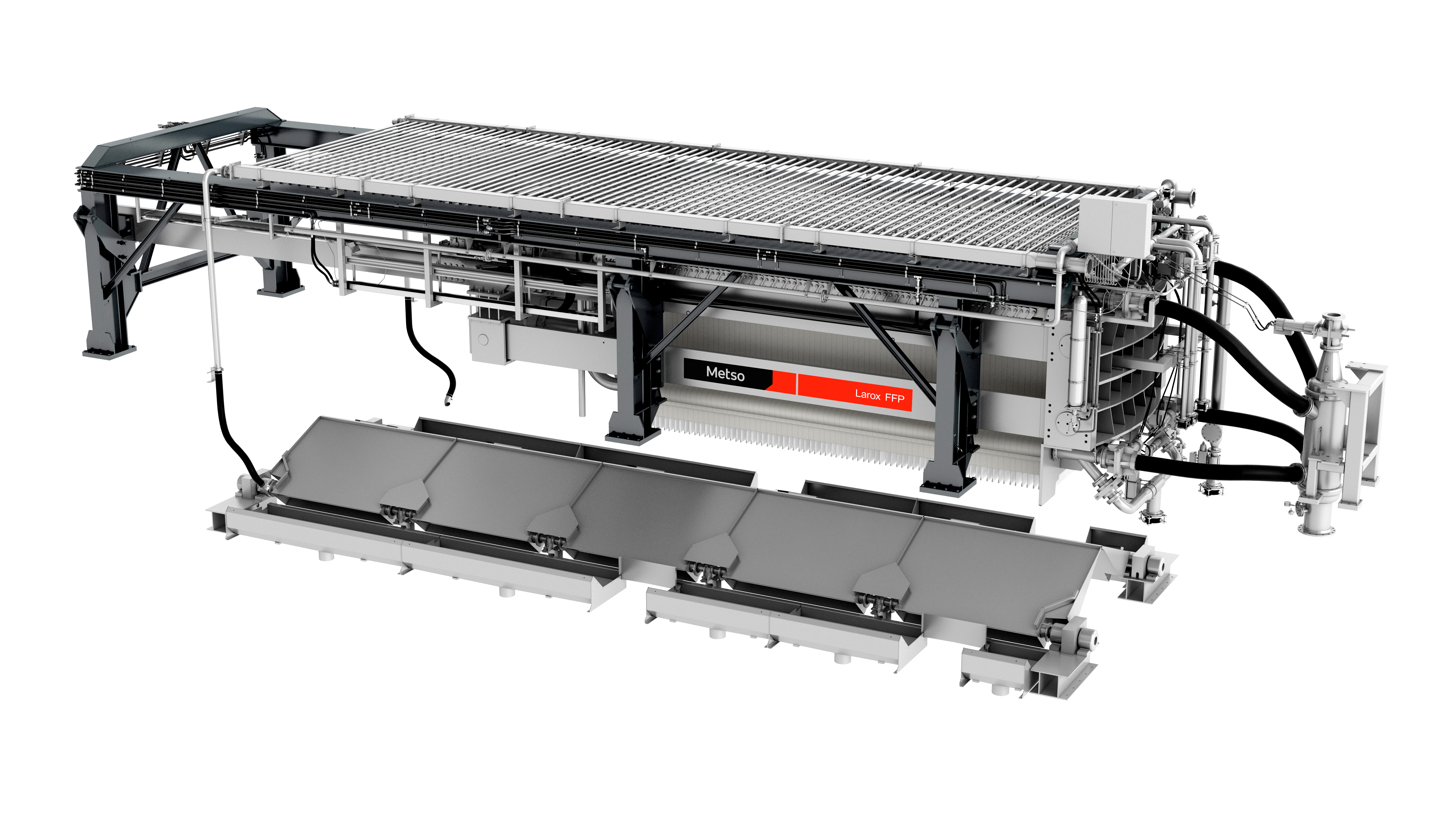

- Aluminum trihydrate washing and filtration

- Calcination

- Alumina storage