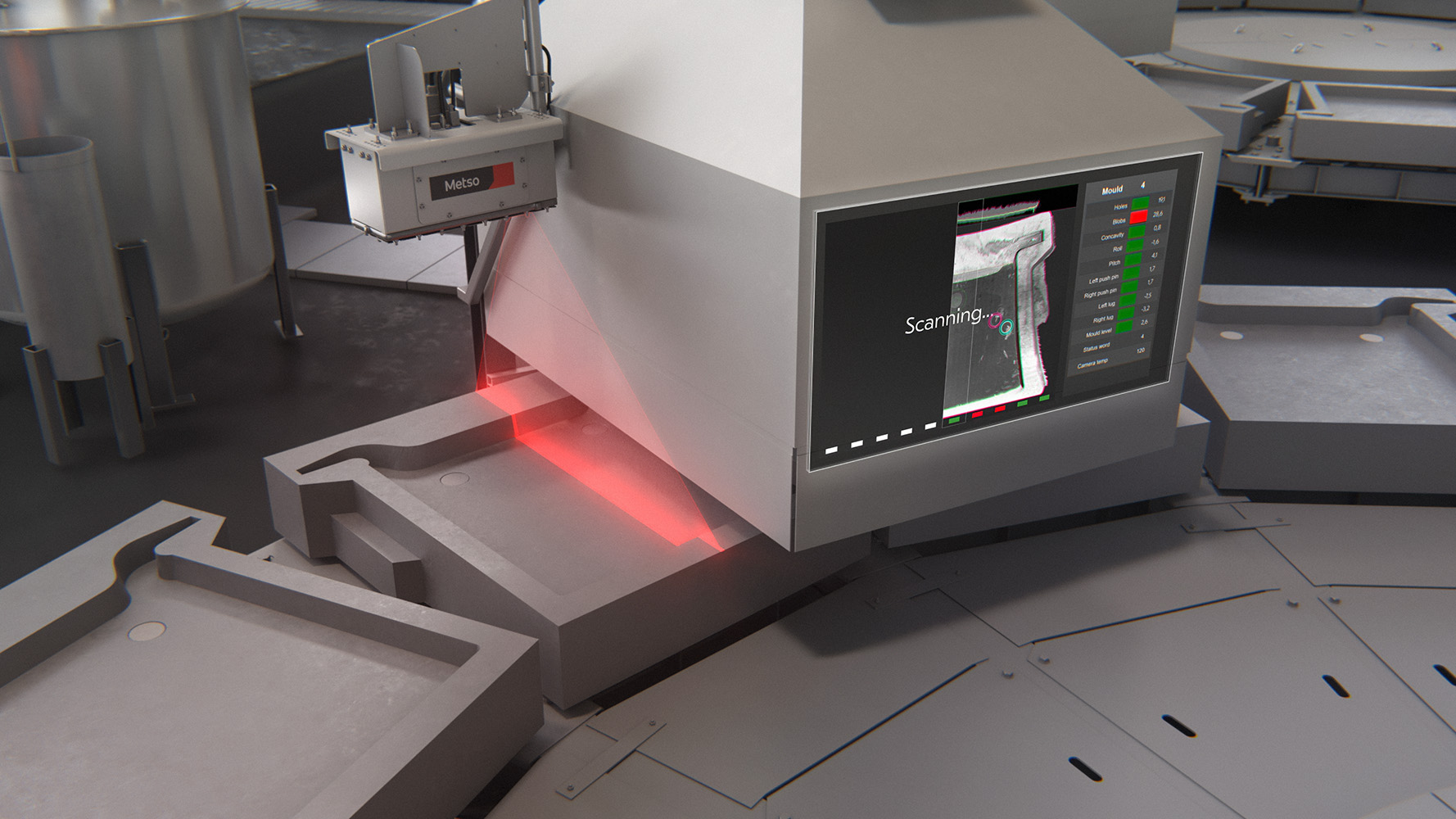

- Minimizes rejection rates through high reliability and anode quality

- Uses accurate and reliable self-adjusting operation

- Results in a fast and flexible material-handling chain

- Gives you safe and simple operation due to easy monitoring and robust control system

- Improves safety with new systems that are available without hydraulics