- Reduced OPEX due to efficient heating and processing

- Reduced emissions

- Ease of maintenance

- Safety features to prevent high-consequence risks

- Clean off-gases

Features

Supporting your operations, from plant design expertise to equipment, parts and services for every stage of your process.

Are you looking to increase production, reduce risks, lower operating costs and enhance environmental performance? Then you are in the right place.

From the design and supply of products for a greenfield plant, to the addition of a single machine for an existing production line, we are here to help.

Rely on OEM experts because not all parts are created equal. Spare and wear parts built to perform.

Helping you get the most out of your equipment and processes.

The Outotec Anode Furnace is supplied with all key equipment for operation of the furnace.

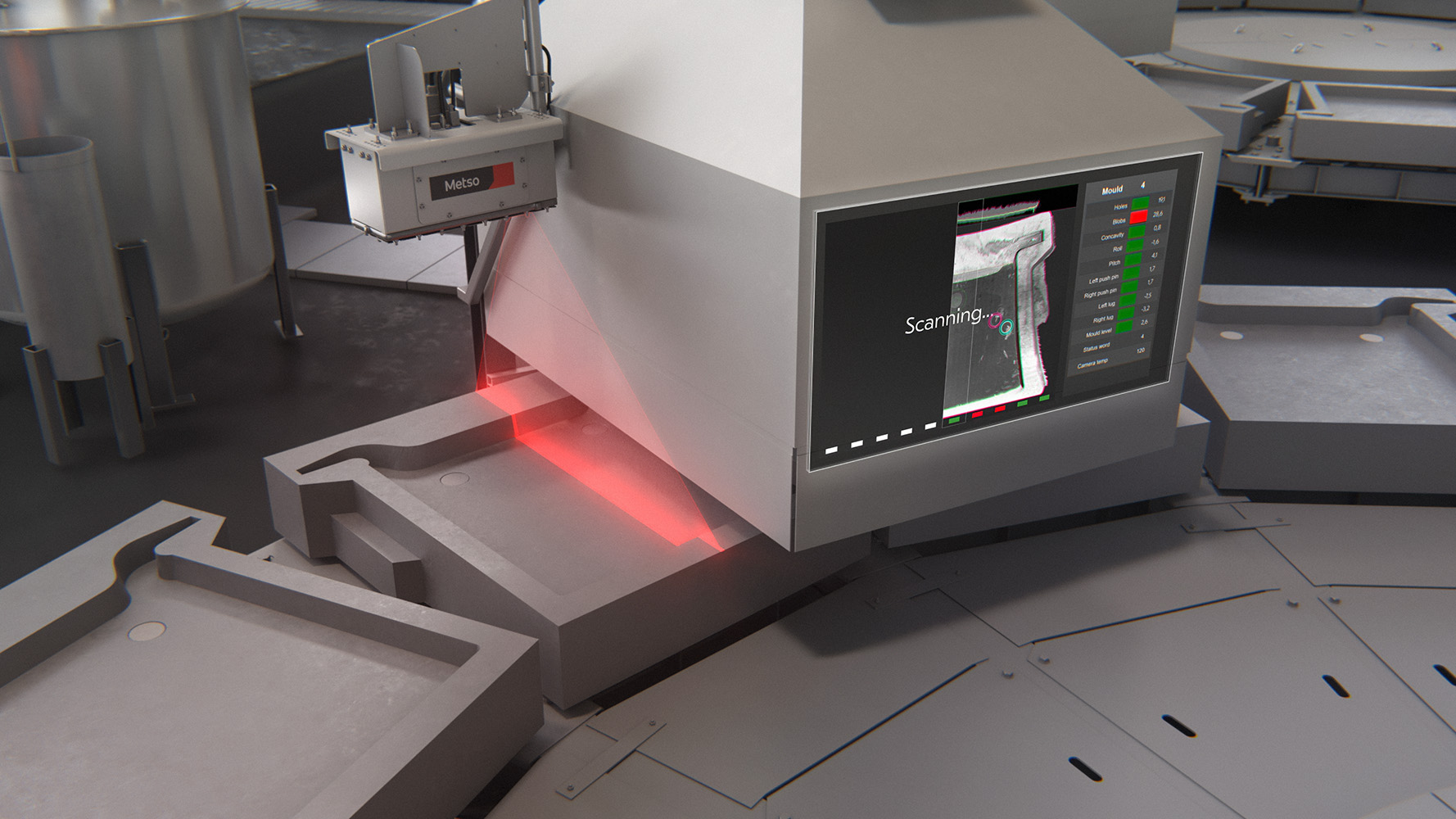

The furnace design is matched with customer needs in brown- and greenfield applications. Metso’s holistic competence in smelter process optimization and integration of automation systems ensures that the furnaces are seamlessly integrated into the processing chain. The delivery project combined with services and on-site support ensures a smooth commissioning and start-up.